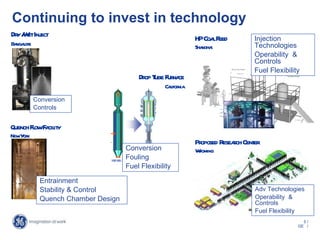

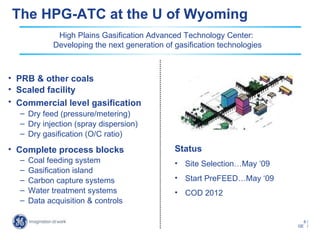

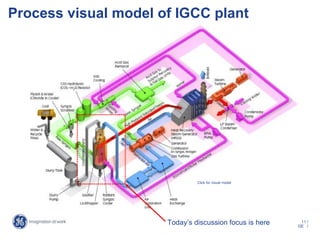

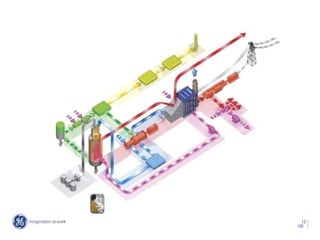

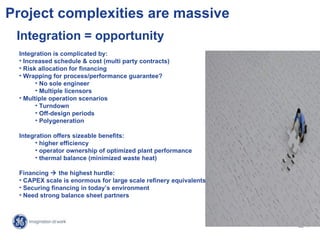

The document discusses GE's experience and leadership in gasification technologies, describing their proposed configuration for an indirect coal-to-liquids plant using Illinois #6 coal to produce 28,000 barrels per day of diesel and 14,000 barrels per day of naphtha. It outlines critical elements like syngas quality treatment, and notes project complexities involving integration challenges and the enormous capital costs required for large-scale plants. Key performance metrics highlighted include a CO2 production rate of 0.23 tonnes per barrel of CTL product and a water requirement of 2.3 barrels of water per barrel of CTL.