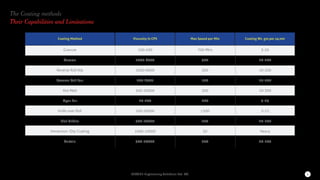

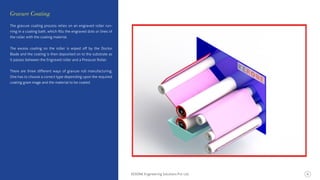

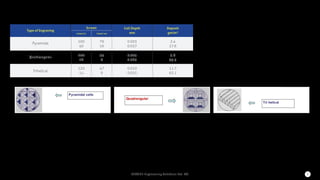

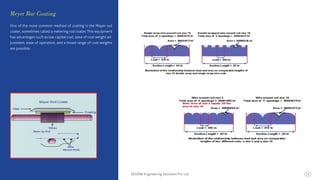

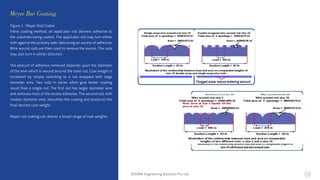

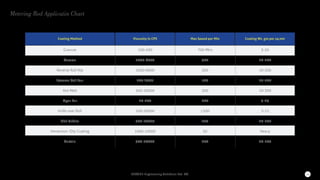

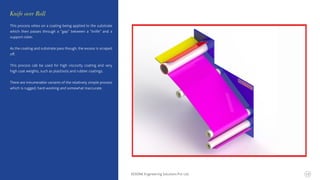

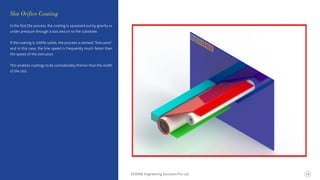

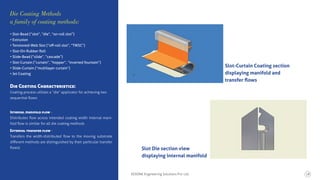

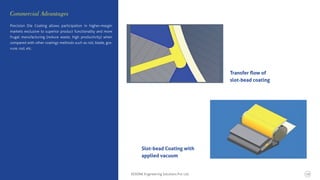

Kerone Engineering Solutions aims to be a global leader in specialized industrial heating, cooling, and drying solutions while focusing on customer-centric engineering and high ethical standards. The document details various coating methods in manufacturing, comparing their processes, applications, and advantages, including gravure, reverse roll, and knife over roll coatings. It emphasizes the importance of choosing the right equipment and adhesive properties for effective coating application.