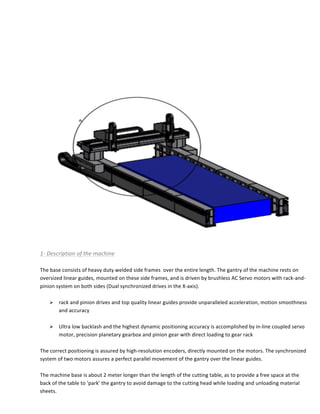

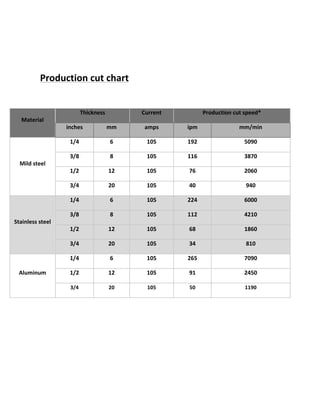

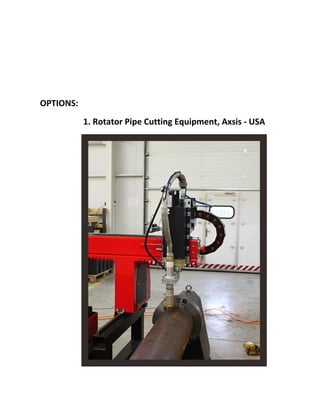

The document describes a CNC gantry plasma cutting system from Axsis in the USA. The system has a cutting area of 2m x 6m and includes an Air Plasma power source from Hypertherm that can cut materials up to 38mm thick. Optional equipment include a rotary pipe cutting attachment and fume extraction system. The summary provides the key details about the plasma cutting system and its specifications.