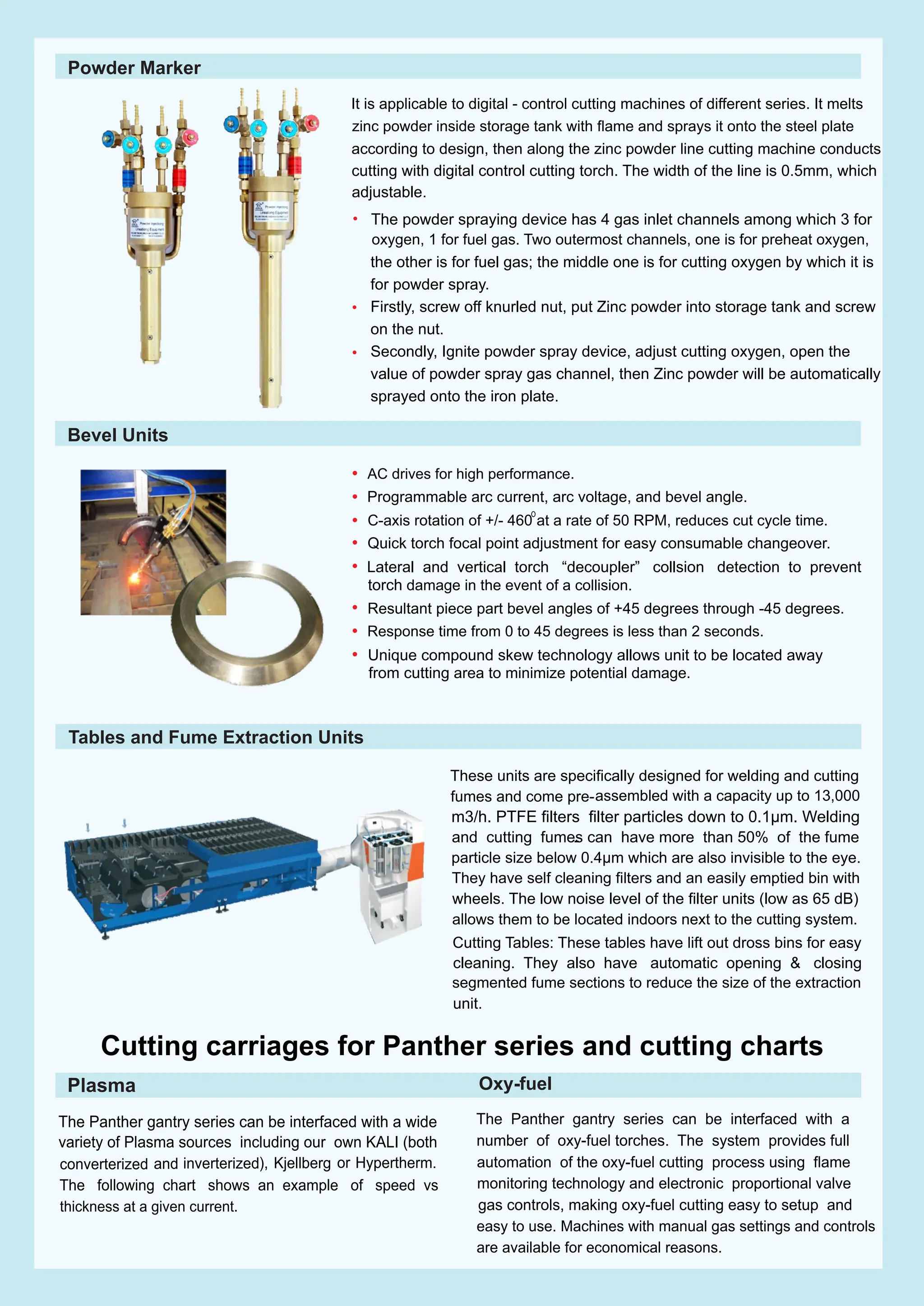

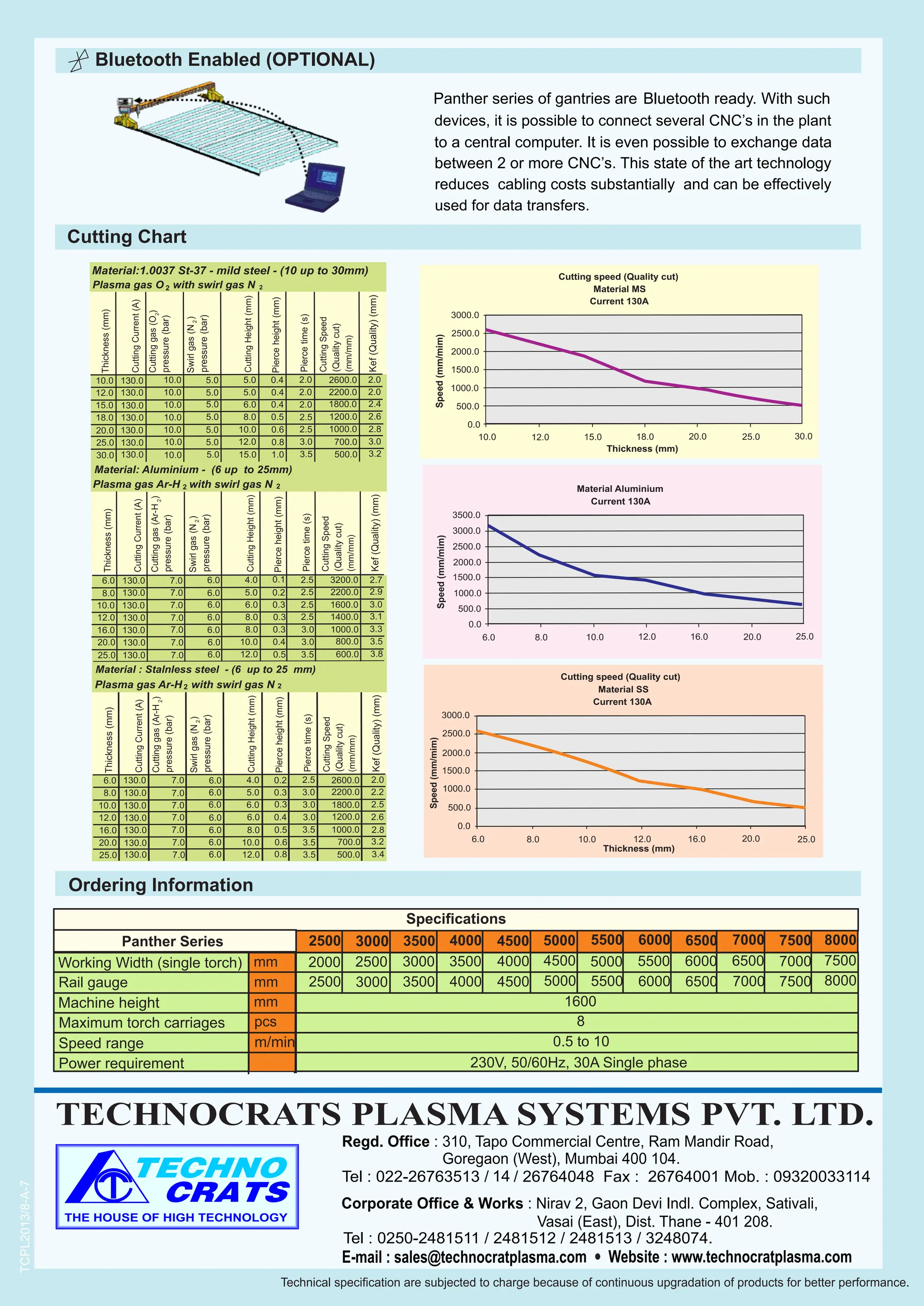

The Panther series gantry systems feature high-speed, dual-sided cutting capabilities with precision technologies for consistent performance over time. Key specifications include advanced cutting methods (plasma and oxy-fuel), high accuracy and repeatability, and a robust service network offering real value. The systems are also equipped with user-friendly interfaces, automatic features for height control, and options for connectivity, significantly enhancing operational efficiency.