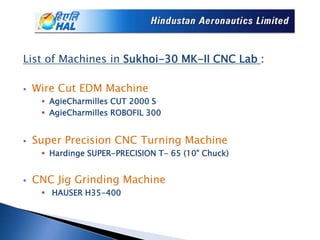

Hindustan Aeronautics Limited (HAL) was established on October 1, 1964, through the merger of multiple companies and achieved Navratna status in 2007. HAL aims to become a significant global player in the aerospace industry, focusing on self-reliance in the design, development, and manufacturing of aerospace equipment. The document details various products, CNC machines, and specifications related to HAL's operations and technologies.