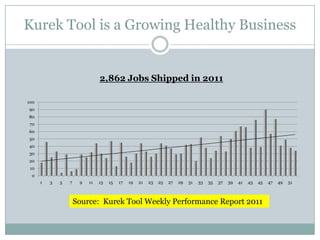

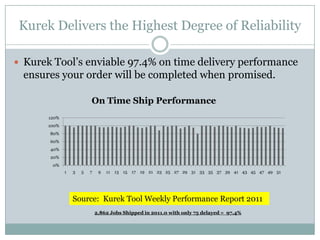

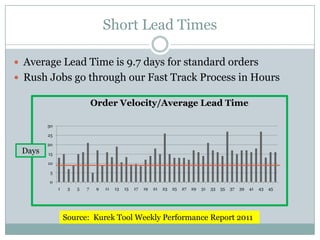

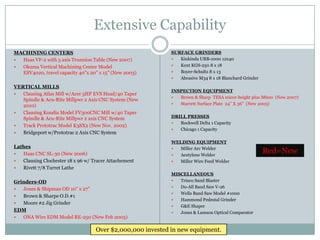

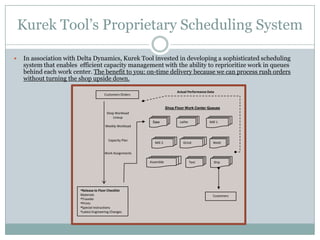

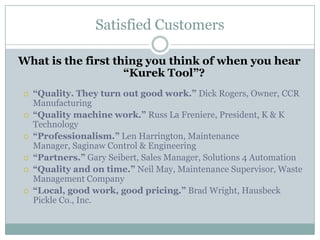

Kurek Tool is a precision machining business that prides itself on quality work, reliability, and short lead times. It has experienced steady growth, shipping over 2,800 jobs in 2011. The company invests heavily in new equipment and uses a proprietary scheduling system to achieve on-time delivery rates over 97%. Customers praise Kurek Tool for its professionalism, quality work, and partnership approach.