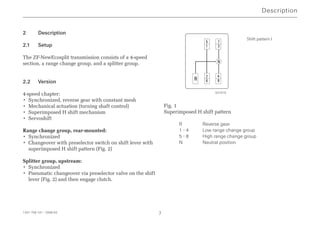

This document provides operating instructions for a ZF synchromesh transmission. It begins with an overview of the transmission components and shift actuation methods. It then provides guidance on starting the vehicle, engaging the clutch, shifting gears, engaging power take-offs, parking, towing, and maintenance. Proper operation and maintenance are emphasized to ensure reliability and cost-effective driving.

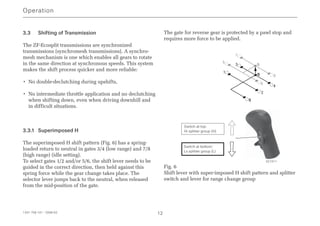

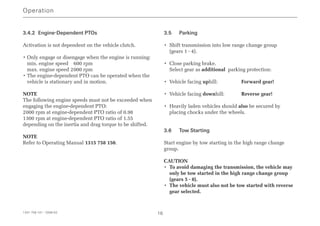

![3.7 Towing

Vehicles may only be towed under the following

conditions:

• Emergency steering pump fitted

• High range selected, shift lever in neutral position

• Towing distance of max. 100 km

• The max. permissible towing speed should be defined

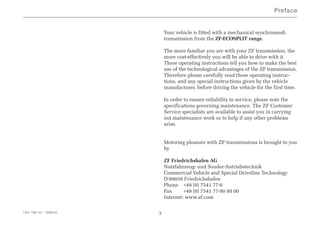

depending on axle ratio and tire size using the diagram

provided (also refer to Fig. 8).

NOTE

Vehicle manufacturer specifications MUST be observed.

CAUTION

If one of the aforementioned conditions is not satisfied,

the propshaft must always be deflanged from the rear

axle or the stub shafts must be removed in order to

prevent transmission damage from occurring.

If you suspect transmission damage, the propshaft must

also be deflanged from the rear axle or the stub shafts

must be removed.

Fig. 8

Example (reading): iAxle = 6, Rdyn = 0.5 m

Towing speed from diagram:

Vmax = 25 km/h

NOTE

Relevant local legislation relating to max. towing speeds

must be observed.

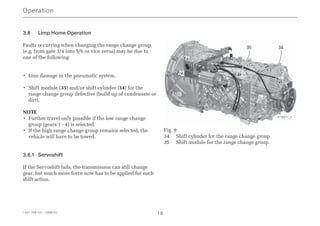

Operation

1341 758 101 - 2006-02 17

2.0

3.0

4.0

5.0

6.0

7.0

8.0

10 15 20 25 30 35 40 45 50

[i Axle]

V [km/h]

Rdyn 0.5 [m] (z.B. 275/80R22.5)

Rdyn 0.6 [m] (z.B. F24)

Rdyn 0.4 [m] (z.B. 245/70R19.5)

027279_en](https://image.slidesharecdn.com/zfecosplit1341758101operatinginstructions-220827153154-2cdd1e15/85/ZF-Ecosplit-1341_758_101-Operating-Instructions-pdf-17-320.jpg)