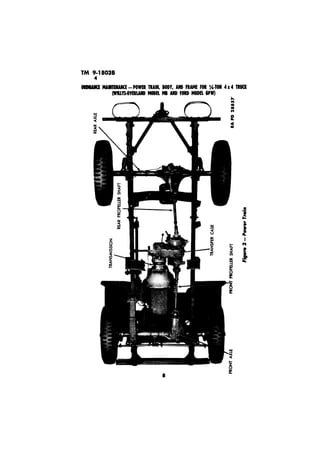

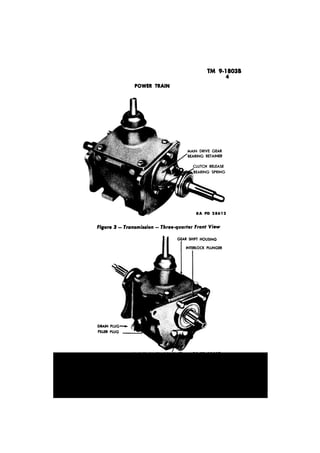

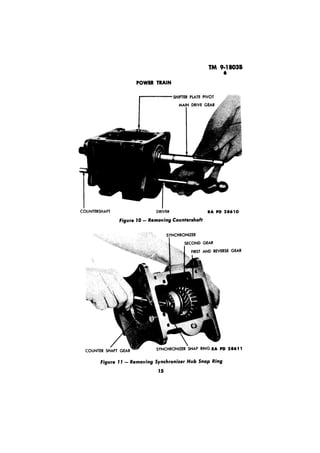

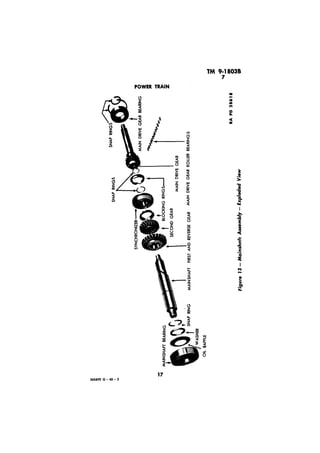

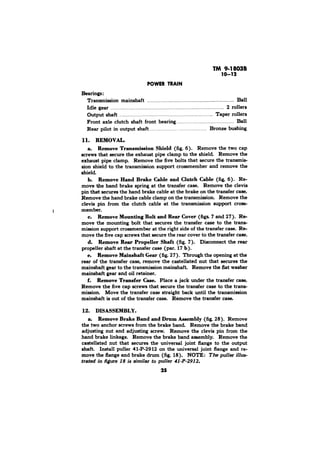

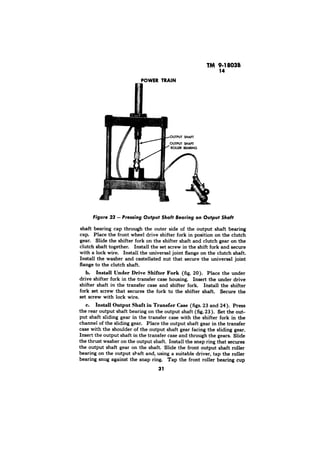

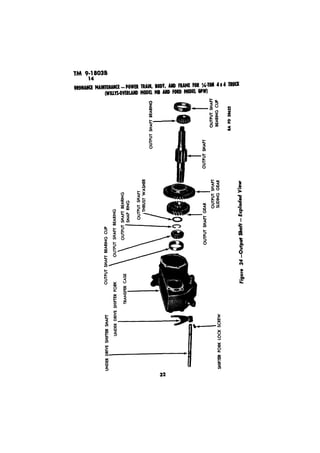

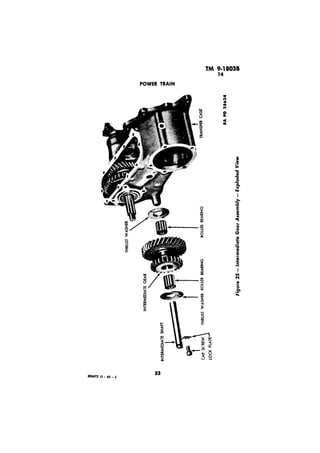

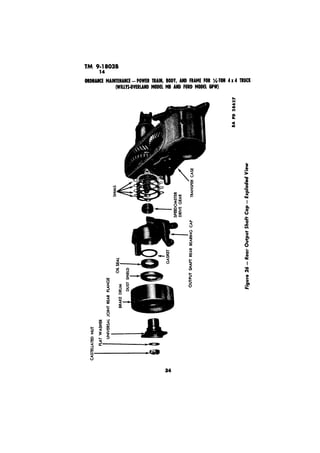

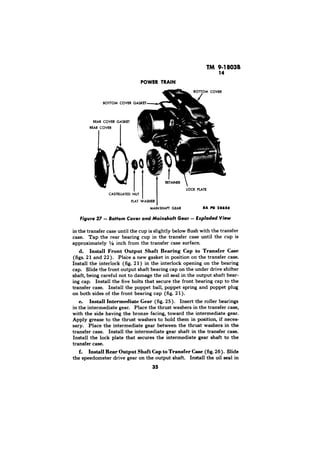

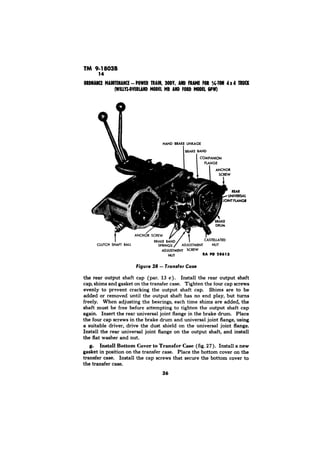

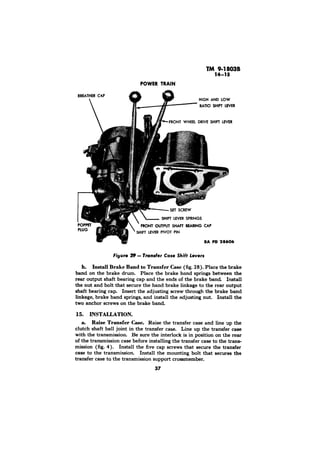

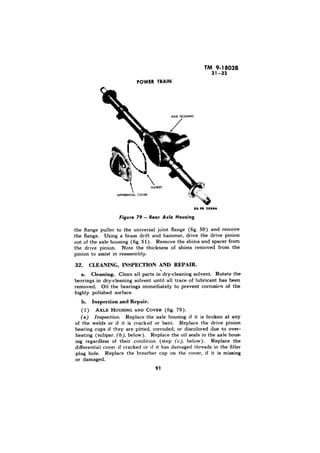

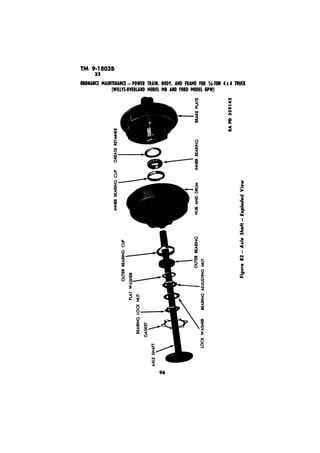

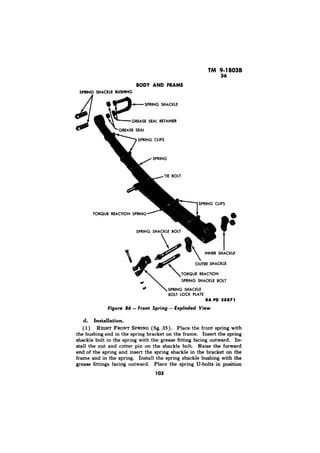

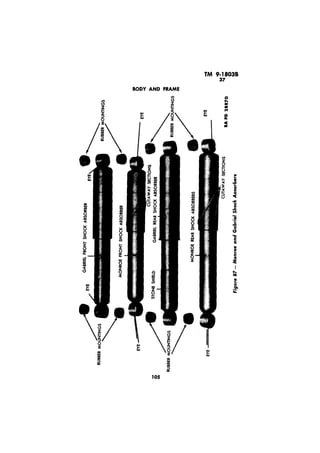

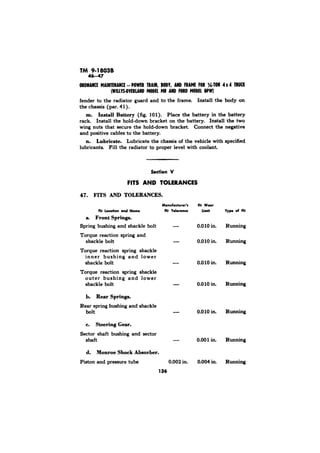

This document provides descriptions and specifications for the power train components of a vehicle, including the transmission, transfer case, front and rear axles, and related linkages. It describes the transmission as a 3-speed unit with synchronized second and high gears. Specifications are provided for components like gears, shafts, ratios, and bearings. Procedures are outlined for disassembly, cleaning, inspection, and identifying parts that require replacement.