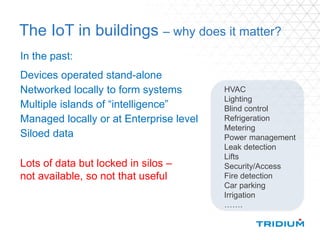

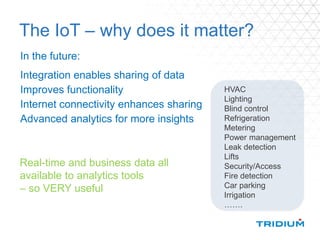

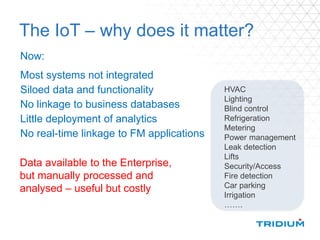

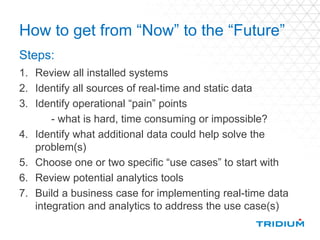

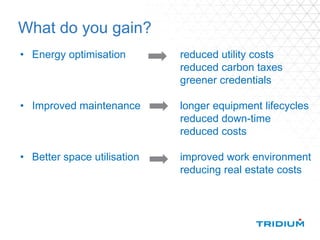

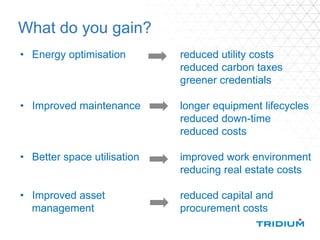

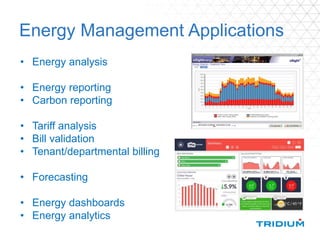

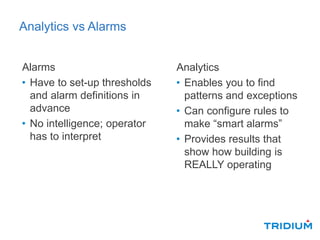

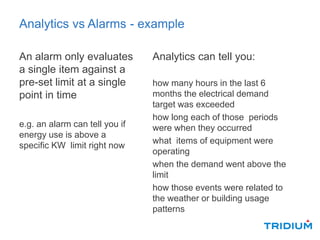

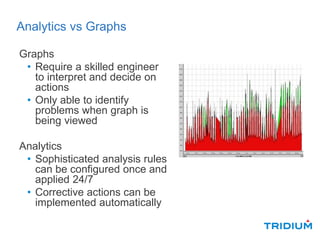

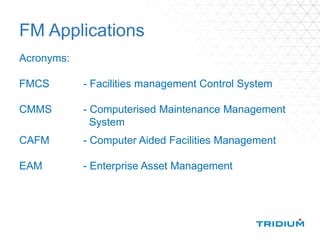

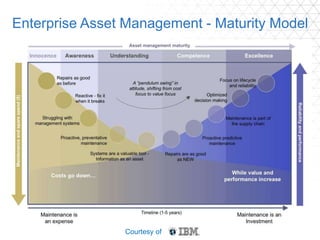

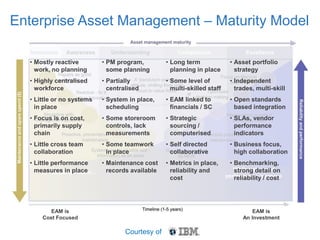

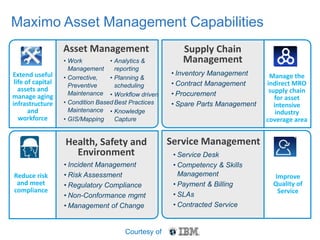

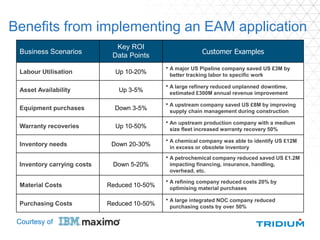

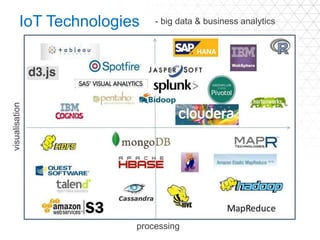

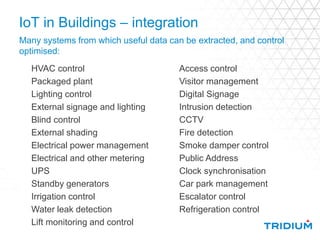

The document discusses the Internet of Things (IoT) and its applications in facilities management. It begins by defining the IoT as the network of physical objects embedded with sensors, software and connectivity that allows them to collect and exchange data. It describes how the IoT enables monitoring and control of devices, analytics using large amounts of connected device data, and integration of systems across industries like manufacturing, cities and commercial buildings. For facilities management, the IoT allows data from different building systems to be shared and analyzed for improved functionality, energy optimization, and predictive maintenance. The document outlines a process for facilities managers to implement the IoT and provides examples of energy management, building analytics and facilities management applications that can be used. It also discusses