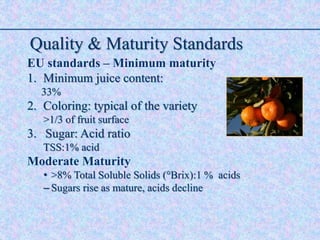

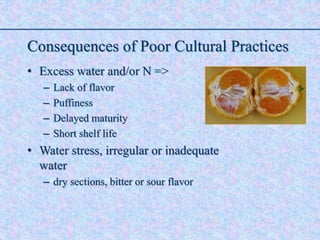

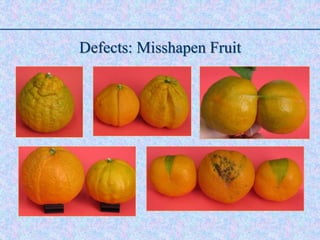

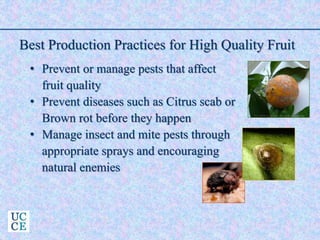

This document discusses harvesting citrus for quality. It outlines factors that influence citrus quality like maturity, sugar to acid ratio, and freedom from defects. Good production practices like pruning, pest management and fertilization promote quality fruit. Fruit should be harvested at maturity by hand and handled gently to avoid damage. Maturity is assessed using tests for juice content, sugar levels, and acidity. Meeting minimum maturity standards is important for exports and high-end markets. Following best harvesting and post-harvest practices ensures citrus reaches consumers in top condition for the best prices.