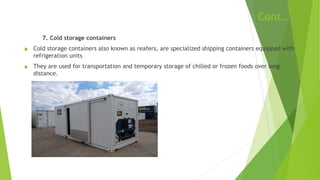

Chilling refers to reducing the temperature of food above freezing but below 15 degrees Celsius to slow microbial growth and chemical reactions. This preserves sensory and nutritional properties while inhibiting spoilage. Effective chilling requires proper temperature control, packaging, storage conditions, humidity, airflow and equipment like refrigerators, blast chillers and cold rooms. Chilling can impact texture, nutrients, moisture and biochemical changes in foods but is crucial for preserving quality and safety when followed correctly.