Embed presentation

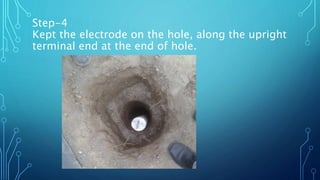

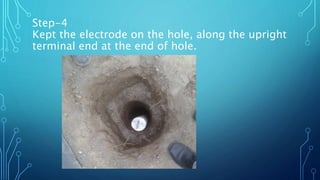

This document describes the process of installing a chemical pipe earthing system as an alternative to a conventional earthing system using salt and charcoal. The chemical pipe earthing system uses an electrode made of galvanized iron inserted into a bored hole filled with bentonite, a chemical compound that maintains conductivity without being corrosive like salt. A six-step process is outlined for installing the electrode and connecting it to equipment via a buried copper strip to safely earth the electric circuit.