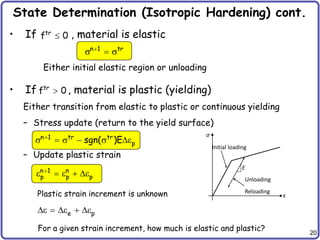

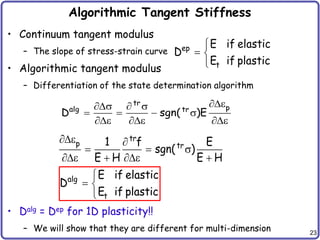

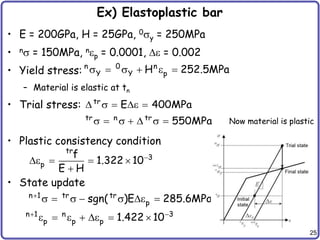

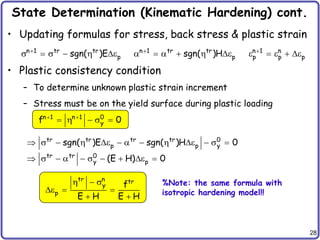

The document is a chapter by Prof. Samirsinh Parmar on 1D elastoplasticity, covering key concepts such as the difference between elasticity and plasticity, hardening models, and mathematical formulations related to elastoplastic behavior. It also includes sections on practical applications, analysis procedures, and algorithms for isotropic hardening, alongside MATLAB code and exercises for further understanding. Additionally, it discusses finite element formulations used in elastoplastic analysis, providing a comprehensive guide for civil engineering applications.

![14

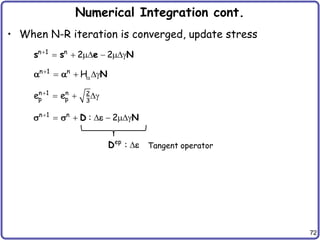

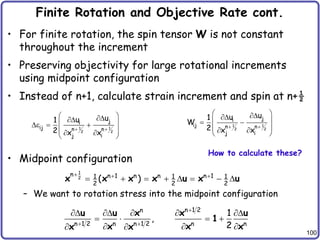

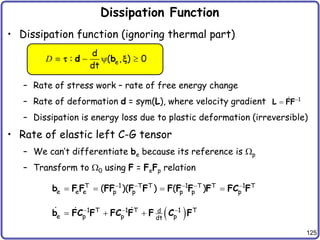

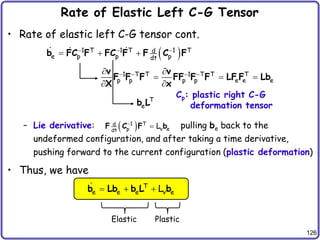

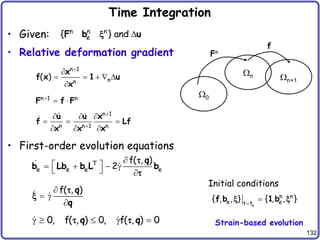

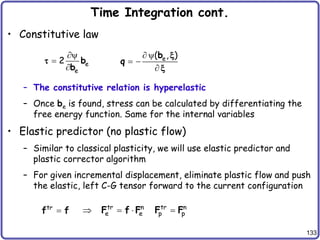

1D Finite Element Formulation

• Load increment

– applied load is divided by N increments: [t1, t2, …, tN]

– analysis procedure has been completed up to load increment tn

– a new solution at tn+1 is sought using the Newton-Raphson method

– iteration k has been finished and the current iteration is k+1

• Displacement increments

– From last increment tn:

– From previous iteration:

x1 x2

u1 u2

P1 P2

L

k n 1 k n

k n 1 k 1 n 1 k

d d d

d d d

1

2

u

u

d](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-14-320.jpg)

![15

1D FE Formulation cont.

• Interpolation

• Weak form (1 element)

– Internal force = external force

1

1 2

2

u

u(x) [N N ]

u

N d

1

2

u

d 1 1

u

dx L L u

e

B d

u

e

N d

B d

L

T T n 1 k 1 T n 1 2

0

Adx , R

s

d B d F d 1

2

u

u

d](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-15-320.jpg)

![32

MATLAB Program combHard1D

%

% 1D Linear combined isotropic/kinamtic hardening model

%

function [stress, alpha, ep]=combHard1D(mp, deps, stressN, alphaN, epN)

% Inputs:

% mp = [E, beta, H, Y0];

% deps = strain increment

% stressN = stress at load step N

% alphaN = back stress at load step N

% epN = plastic strain at load step N

%

E=mp(1); beta=mp(2); H=mp(3); Y0=mp(4); %material properties

ftol = Y0*1E-6; %tolerance for yield

stresstr = stressN + E*deps; %trial stress

etatr = stresstr - alphaN; %trial shifted stress

fyld = abs(etatr) - (Y0+(1-beta)*H*epN); %trial yield function

if fyld < ftol %yield test

stress = stresstr; alpha = alphaN; ep = epN;%trial states are final

return;

else

dep = fyld/(E+H); %plastic strain increment

end

stress = stresstr - sign(etatr)*E*dep; %updated stress

alpha = alphaN + sign(etatr)*beta*H*dep; %updated back stress

ep = epN + dep; %updated plastic strain

return;](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-32-320.jpg)

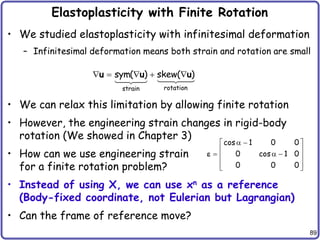

![33

Ex) Two bars in parallel

• Bar 1: A = 0.75, E = 10000, Et = 1000, 0sY = 5, kinematic

• Bar 2: A = 1.25, E = 5000, Et = 500, 0sY = 7.5, isotropic

• MATLAB program

%

% Example 4.5 Two elastoplastic bars in parallel

%

E1=10000; Et1=1000; sYield1=5;

E2=5000; Et2=500; sYield2=7.5;

mp1 = [E1, 1, E1*Et1/(E1-Et1), sYield1];

mp2 = [E2, 0, E2*Et2/(E2-Et2), sYield2];

nS1 = 0; nA1 = 0; nep1 = 0;

nS2 = 0; nA2 = 0; nep2 = 0;

A1 = 0.75; L1 = 100;

A2 = 1.25; L2 = 100;

tol = 1.0E-5; u = 0; P = 15; iter = 0;

Res = P - nS1*A1 - nS2*A2;

Dep1 = E1; Dep2 = E2;

conv = Res^2/(1+P^2);

fprintf('niter u S1 S2 A1 A2');

fprintf(' ep1 ep2 Residual');

fprintf('n %3d %7.4f %7.3f %7.3f %7.3f %7.3f %8.6f %8.6f %10.3e',...

iter,u,nS1,nS2,nA1,nA2,nep1,nep2,Res);

Bar1

Bar2

Rigid 15](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-33-320.jpg)

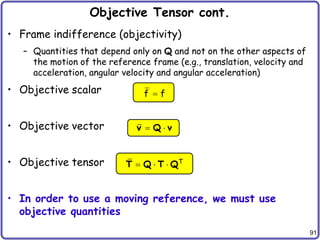

![34

Ex) Two bars in parallel cont.

while conv > tol && iter < 20

delu = Res / (Dep1*A1/L1 + Dep2*A2/L2);

u = u + delu;

delE = delu / L1;

[Snew1, Anew1, epnew1]=combHard1D(mp1,delE,nS1,nA1,nep1);

[Snew2, Anew2, epnew2]=combHard1D(mp2,delE,nS2,nA2,nep2);

Res = P - Snew1*A1 - Snew2*A2;

conv = Res^2/(1+P^2);

iter = iter + 1;

Dep1 = E1; if epnew1 > nep1; Dep1 = Et1; end

Dep2 = E2; if epnew2 > nep2; Dep2 = Et2; end

nS1 = Snew1; nA1 = Anew1; nep1 = epnew1;

nS2 = Snew2; nA2 = Anew2; nep2 = epnew2;

fprintf('n %3d %7.4f %7.3f %7.3f %7.3f %7.3f %8.6f %8.6f %10.3e',...

iter,u,nS1,nS2,nA1,nA2,nep1,nep2,Res);

end

Iteration u s1 s2 ep1 ep2 Residual

0 0.0000 0.000 0.000 0.000000 0.000000 1.50E+1

1 0.1091 5.591 5.455 0.000532 0.000000 3.99E+0

2 0.1661 6.161 7.580 0.001045 0.000145 9.04E 1

3 0.2318 6.818 7.909 0.001636 0.000736 0.00E+0](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-34-320.jpg)

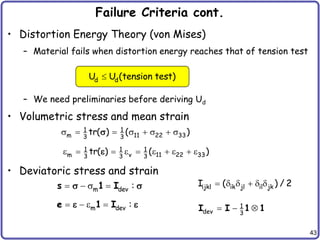

![44

Failure Criteria cont.

• Example: Linear elastic material

• Distortion energy density

[ 2 ] : :

1 1 I D

s e e

m m

m

(3 ) 2 ( )

(3 2 ) 2

deviatoric

volumetric

s e e

e

1 e 1

1 e

m m

(3 2 )

2

s e

s e

1 1

d 2 4

U : :

s e s s

3

1 1 1

m m m m

2 2 2 2

U : ( ) : ( ) :

s e s e

1 s 1 e s e

s e

Bulk modulus

3 2

K

3

](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-44-320.jpg)

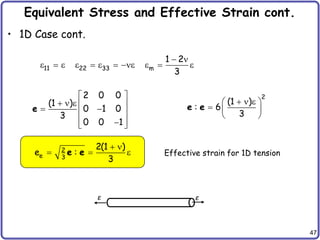

![49

Von Mises Criterion cont.

• J2: second invariant of s

• Von Mises yield function

2

1 1

2 2 2

J [ : tr( ) ] :

s s s s s

2

2 Y

3J 0

s

2

3

Y

2

: 0

s

s s

2

Y

3

: 0

s

s s

2

Y

3

0

s

s

Yield function

s1

s2

2

Y

3

s

s

radius

Elastic

state

Impossible

state

Material

yields

Yield surface is circular in

deviatoric stress space](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-49-320.jpg)

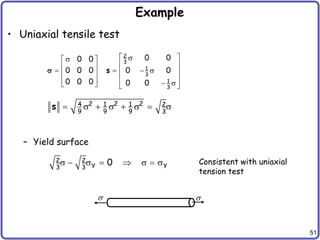

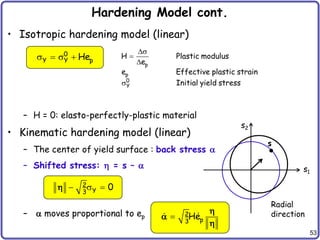

![54

Hardening Model cont.

• Combined Hardening

– Many materials show both isotropic and kinematic hardenings

– Introduce a parameter [0, 1] to consider this effect

– Baushinger effect: The yield stress increases in one directional

loading. But it decreases in the opposite directional load.

– This is caused by dislocation pileups and tangles (back stress).

When strain direction is changed, this makes the dislocations easy

to move

– Isotropic hardening: = 0

– Kinematic hardening: = 1

0

2

Y p

3

[ (1 )He ] 0

s

2

p

3

He

](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-54-320.jpg)

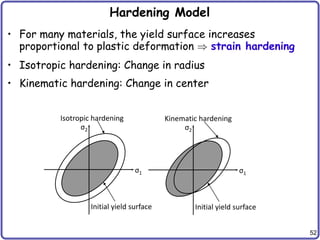

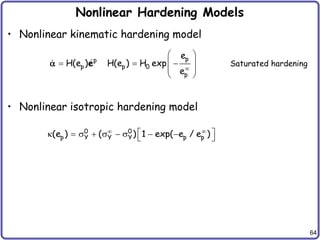

![65

Example: Linear hardening model

• Linear combined hardening model, associative flow rule

• 5 params: 2 elastic (, ) and 3 plastic (, H, sY

0) variables

• Plastic consistency parameter

k s p

0 2

p Y p 3

(e ) (1 )He He

s

0

2

p Y p

3

f( , ,e ) [ (1 )He ] 0

s s

2

p p

3

p

f f f

f : : e : : (1 )He 0

e

s N s N

s

g

g

g

p

p

2 2

3 3

2

p 3

2 2 2

H H

e

s e e e N

e N](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-65-320.jpg)

![78

Implementation of Elastoplasticity

• We will explain for a 3D solid element at a Gauss point

• Voigt notation

• Inputs

(a) Finite Element (b) Reference Element

x

z

(1,1,–1)

(1,1,1)

(–1,1,1)

(–1,1,–1)

x1

x2

x3

x4

x5

x6

x7

x8

x2

x1

x3

(1, –1,–1)

(1, –1,1)

(–1, –1,1)

T

11 22 33 12 23 13

{ } [ ]

s s s s s s

s

T

11 22 33 12 23 13

{ } [ 2 2 2 ]

e e e e e e

e

T

I I1 I2 I3

d d d

d

T

n n n n n n n

11 22 33 12 23 13

s s s s s s

s

T

n n n n n n n n

11 22 33 12 23 13 p

e

x](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-78-320.jpg)

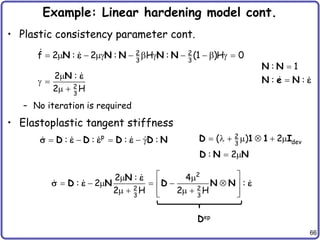

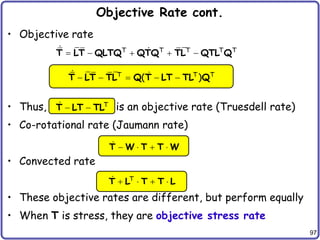

![80

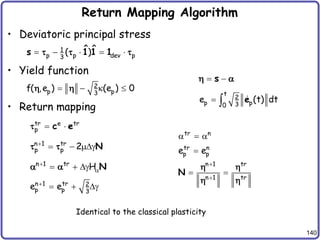

Return Mapping Algorithm

• Elastic predictor

– Unit tensor

– Trial stress

– Trace of stress

– Shifted stress

– Norm

– Yield function

T

1 1 1 0 0 0

1

tr n

C

s s e

tr tr tr

11 22 33

tr( ) s s s

s

tr tr n

1

3

tr( )

s s

tr tr 2 tr 2 tr 2 tr 2 tr 2 tr 2

11 22 33 12 23 13

( ) ( ) ( ) 2[( ) ( ) ( ) ]

tr 0 n

2

Y p

3

f (1 )He

s

](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-80-320.jpg)

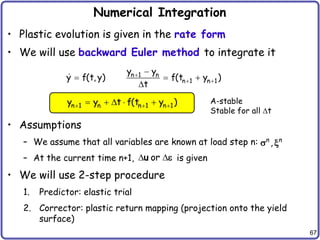

![82

Implementation of Elastoplasticity cont.

• Consistent tangent matrix

• Internal force and tangent stiffness matrix

• Solve for incremental displacement

• The algorithm repeats until the residual reduces to zero

• Once the solution converges, save stress and plastic

variables and move to next load step

2 2

1 2

2 tr

3

4 4

c c

2 H

g

alg T

1 2 2 dev

(c c ) c

D D NN I

ext int

T

[ ]{ } { } { }

K u f f

4 NG

int T n 1

I K K

I 1K 1

( )

f B J

s

4 4 NG

alg

T

T I J K K

I 1 J 1K 1

( )

K B D B J

2 1 1

3 3 3

1 2 1

3 3 3

1 1 2

dev 3 3 3

1

2

1

2

1

2

0 0 0

0 0 0

0 0 0

0 0 0 0 0

0 0 0 0 0

0 0 0 0 0

I](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-82-320.jpg)

![83

Program combHard.m

%

% Linear combined isotropic/kinematic hardening model

%

function [stress, alpha, ep]=combHard(mp,D,deps,stressN,alphaN,epN)

% Inputs:

% mp = [lambda, mu, beta, H, Y0];

% D = elastic stiffness matrix

% stressN = [s11, s22, s33, t12, t23, t13];

% alphaN = [a11, a22, a33, a12, a23, a13];

%

Iden = [1 1 1 0 0 0]';

two3 = 2/3; stwo3=sqrt(two3); %constants

mu=mp(2); beta=mp(3); H=mp(4); Y0=mp(5); %material properties

ftol = Y0*1E-6; %tolerance for yield

%

stresstr = stressN + D*deps; %trial stress

I1 = sum(stresstr(1:3)); %trace(stresstr)

str = stresstr - I1*Iden/3; %deviatoric stress

eta = str - alphaN; %shifted stress

etat = sqrt(eta(1)^2 + eta(2)^2 + eta(3)^2 ...

+ 2*(eta(4)^2 + eta(5)^2 + eta(6)^2));%norm of eta

fyld = etat - stwo3*(Y0+(1-beta)*H*epN); %trial yield function

if fyld < ftol %yield test

stress = stresstr; alpha = alphaN; ep = epN;%trial states are final

return;

else

gamma = fyld/(2*mu + two3*H); %plastic consistency param

ep = epN + gamma*stwo3; %updated eff. plastic strain

end

N = eta/etat; %unit vector normal to f

stress = stresstr - 2*mu*gamma*N; %updated stress

alpha = alphaN + two3*beta*H*gamma*N; %updated back stress](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-83-320.jpg)

![84

Program combHardTan.m

function [Dtan]=combHardTan(mp,D,deps,stressN,alphaN,epN)

% Inputs:

% mp = [lambda, mu, beta, H, Y0];

% D = elastic stiffness matrix

% stressN = [s11, s22, s33, t12, t23, t13];

% alphaN = [a11, a22, a33, a12, a23, a13];

%

Iden = [1 1 1 0 0 0]';

two3 = 2/3; stwo3=sqrt(two3); %constants

mu=mp(2); beta=mp(3); H=mp(4); Y0=mp(5); %material properties

ftol = Y0*1E-6; %tolerance for yield

stresstr = stressN + D*deps; %trial stress

I1 = sum(stresstr(1:3)); %trace(stresstr)

str = stresstr - I1*Iden/3; %deviatoric stress

eta = str - alphaN; %shifted stress

etat = sqrt(eta(1)^2 + eta(2)^2 + eta(3)^2 ...

+ 2*(eta(4)^2 + eta(5)^2 + eta(6)^2));%norm of eta

fyld = etat - stwo3*(Y0+(1-beta)*H*epN); %trial yield function

if fyld < ftol %yield test

Dtan = D; return; %elastic

end

gamma = fyld/(2*mu + two3*H); %plastic consistency param

N = eta/etat; %unit vector normal to f

var1 = 4*mu^2/(2*mu+two3*H);

var2 = 4*mu^2*gamma/etat; %coefficients

Dtan = D - (var1-var2)*N*N' + var2*Iden*Iden'/3;%tangent stiffness

Dtan(1,1) = Dtan(1,1) - var2; %contr. from 4th-order I

Dtan(2,2) = Dtan(2,2) - var2;

Dtan(3,3) = Dtan(3,3) - var2;

Dtan(4,4) = Dtan(4,4) - .5*var2;

Dtan(5,5) = Dtan(5,5) - .5*var2;

Dtan(6,6) = Dtan(6,6) - .5*var2;](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-84-320.jpg)

![85

Program PLAST3D.m

function PLAST3D(MID, PROP, ETAN, UPDATE, LTAN, NE, NDOF, XYZ, LE)

%***********************************************************************

% MAIN PROGRAM COMPUTING GLOBAL STIFFNESS MATRIX RESIDUAL FORCE FOR

% PLASTIC MATERIAL MODELS

%***********************************************************************

%%

....

%LOOP OVER ELEMENTS, THIS IS MAIN LOOP TO COMPUTE K AND F

for IE=1:NE

DSP=DISPTD(IDOF);

DSPD=DISPDD(IDOF);

%....

% LOOP OVER INTEGRATION POINTS

for LX=1:2, for LY=1:2, for LZ=1:2

%

% Previous converged history variables

NALPHA=6;

STRESSN=SIGMA(1:6,INTN);

ALPHAN=XQ(1:NALPHA,INTN);

EPN=XQ(NALPHA+1,INTN);

....

% Computer stress, back stress & effective plastic strain

if MID == 1

% Infinitesimal plasticity

[STRESS, ALPHA, EP]=combHard(PROP,ETAN,DDEPS,STRESSN,ALPHAN,EPN);

....

%

% Tangent stiffness

if LTAN

if MID == 1

DTAN=combHardTan(PROP,ETAN,DDEPS,STRESSN,ALPHAN,EPN);

EKF = BM'*DTAN*BM;

....](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-85-320.jpg)

![95

Cauchy Stress Is an Objective Tensor

• Proof from the relation between stresses

• Proof from coordinate transformation of stress tensor

– Coordinate transformation is opposite to rotation

s T

1

J

FSF

S S

s s

T T T T T T

1 1 1

J J J

FSF QFSF Q Q FSF Q Q Q

x

y

z

x

y

z

b1

b2

b3

s s

1 2 3

( ) ( ) ( ) 1 2 3

xyz xyz xyz

[ ] [ ] [ ] [ ] [ ]

b b b

T T T b b b Q

s s

T

x y z xyz

[ ] [ ] [ ] [ ]

Q Q

s s T

xyz xyz

[ ] [ ][ ] [ ]

Q Q](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-95-320.jpg)

![102

Program rotatedStress.m

%

% Rotate stress and back stress to the rotation-free configuration

%

function [stress, alpha] = rotatedStress(L, S, A)

%L = [dui/dxj] velocity gradient

%

str=[S(1) S(4) S(6);S(4) S(2) S(5);S(6) S(5) S(3)];

alp=[A(1) A(4) A(6);A(4) A(2) A(5);A(6) A(5) A(3)];

factor=0.5;

R = L*inv(eye(3) + factor*L);

W = .5*(R-R');

R = eye(3) + inv(eye(3) - factor*W)*W;

str = R*str*R';

alp = R*alp*R';

stress=[str(1,1) str(2,2) str(3,3) str(1,2) str(2,3) str(1,3)]';

alpha =[alp(1,1) alp(2,2) alp(3,3) alp(1,2) alp(2,3) alp(1,3)]';](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-102-320.jpg)

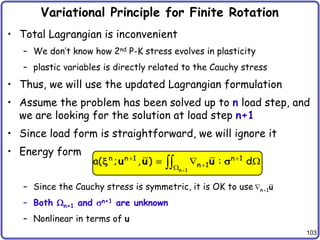

![107

Linearization cont.

• Linearization of energy form cont.

– Express inside of [ ] in terms of

– Constitutive relation:

– Spin term

n 1

n 1

n n 1 T

n 1 n 1

J T

n 1 n 1

L[a( ; , )] : div( ) ( ) d

: div( ) ( ) d

u u u u u

u W W u u

x s s s

s s s s s

alg alg

J

n 1

: : ( )

D D u

s e

n 1

u

m k

i

m i l

u u

u

1 1

im mj mj mj ik ml mk il

2 x x 2 x

1

lj ik kj il n 1 kl

2

W ( ) ( )

( )[ ]

s s s

s s u

1

im mj il jk ik jl n 1 kl

2

W ( )[ ]

s s s u

k

k

u

ij ij kl n 1 kl

x

[ ]

s s u

j

m

u

im il jk n 1 kl

x

[ ]

s s u](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-107-320.jpg)

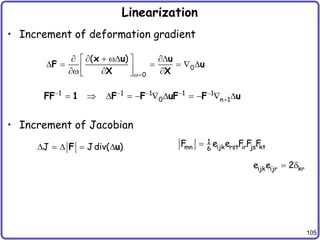

![108

Linearization cont.

• Linearization of energy form cont.

– Initial stiffness term (we need to separate this term)

– Define

n 1

J T

n 1 n 1

L[a( , )] : div( ) ( ) d

u u u W W u u

s s s s s

1

jl ik jk il il jk ik jl ij kl

2

( )

s s s s s

m m m m k

i

r s r s j l

T

n 1 n 1

u u u u u

u

1

rs jl ik

2 x x x x x x

: sym( ) : ( , )

( )

s s

u u u u

s s

* 1

ijkl ij kl il jk jl ik ik jl jk il

2

( )

s s s s s

D

Rotational effect of Cauchy stress tensor](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-108-320.jpg)

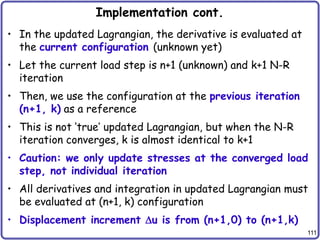

![109

Linearization cont.

• Linearization of energy form cont.

• N-R iteration

* n n 1 n n 1

k k 1 k

a ( , ; , ) ( ) a( ; , ),

u u u u u u u

x x Z

n 1

alg

n n 1 *

n 1 n 1

* n n 1

L[a( ; , )] : ( ) : : ) d

a ( , ; , )

u u u D D u u u

u u u

x s

x

Bilinear

History-dependent

(implicit)](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-109-320.jpg)

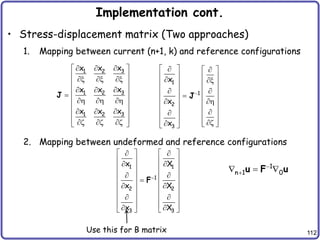

![110

Implementation

• We will explain using a 3D solid element at a Gauss point

using updated Lagrangian form

• The return mapping and consistent tangent operator will

be the same with infinitesimal plasticity

• Voigt Notation

• Inputs

T

11 22 33 12 23 13

{ } [ ]

s s s s s s

s

T

11 22 33 12 23 13

{ } [ 2 2 2 ]

e e e e e e

e

T

I I1 I2 I3

d d d

d

T

n n n n n n n

11 22 33 12 23 13

s s s s s s

s

T

n n n n n n n n

11 22 33 12 23 13 p

e

x](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-110-320.jpg)

![114

Implementation cont.

• Internal force

• Tangent stiffness matrix

• Initial stiffness matrix

4 NG

int T n 1

I k 1 K K

I 1K 1

( )

f B J

s

4 4 NG

alg

T *

T I J K K

I 1 J 1K 1

[ ( ) ]

K B D D B J

11 11 11 12 13

22 22 22 12 23

33 33 33 23 13

*

1 1 1

12 12 11 22 13 23

2 2 2

1 1 1

23 23 13 22 33 12

2 2 2

1 1 1

13 13 23 12 11 33

2 2 2

0

0

0

0 ( )

0 ( )

0 ( )

s s s s s

s s s s s

s s s s s

s s s s s s

s s s s s s

s s s s s s

D

T

4 4 NG

G G

S I J K K

I 1 J 1K 1

[ ]

K B B J

I,1

I,2

I,3

I,1

G

I,2

I

I,3

I,1

I,2

I,3

N 0 0

N 0 0

N 0 0

0 N 0

0 N 0

[ ]

0 N 0

0 0 N

0 0 N

0 0 N

B

9x9

[ ]

0 0

0 0

0 0

s

s

s

This summation is similar to

assembly (must be added to the

corresponding DOFs)](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-114-320.jpg)

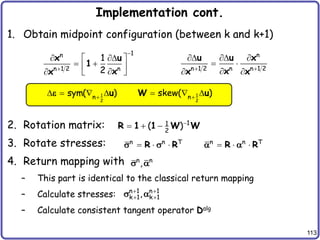

![115

Implementation cont.

• Solve for incremental displacement

• Update displacements

• When N-R iteration converges

– Stress and history dependent variables are stored (updated) to

the global array

– Move on to the next load step

ext int

T S k 1

[ ]{ } { } { }

K K d f f

n 1 n 1

k 1 k k 1

k 1 k 1 k 1

d d d

d d d](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-115-320.jpg)

![116

Program PLAST3D.m

function PLAST3D(MID, PROP, ETAN, UPDATE, LTAN, NE, NDOF, XYZ, LE)

%***********************************************************************

% MAIN PROGRAM COMPUTING GLOBAL STIFFNESS MATRIX RESIDUAL FORCE FOR

% PLASTIC MATERIAL MODELS

%***********************************************************************

....

% Computer stress, back stress & effective plastic strain

elseif MID == 2

% Plasticity with finite rotation

FAC=FAC*det(F);

[STRESSN, ALPHAN] = rotatedStress(DEPS, STRESSN, ALPHAN);

[STRESS, ALPHA, EP]=combHard(PROP,ETAN,DDEPS,STRESSN,ALPHAN,EPN);

....

%

% Tangent stiffness

if LTAN

elseif MID == 2

DTAN=combHardTan(PROP,ETAN,DDEPS,STRESSN,ALPHAN,EPN);

CTAN=[-STRESS(1) STRESS(1) STRESS(1) -STRESS(4) 0 -STRESS(6);

STRESS(2) -STRESS(2) STRESS(2) -STRESS(4) -STRESS(5) 0;

STRESS(3) STRESS(3) -STRESS(3) 0 -STRESS(5) -STRESS(6);

-STRESS(4) -STRESS(4) 0 -0.5*(STRESS(1)+STRESS(2)) -0.5*STRESS(6) -0.5*STRESS(5);

0 -STRESS(5) -STRESS(5) -0.5*STRESS(6) -0.5*(STRESS(2)+STRESS(3)) -0.5*STRESS(4);

-STRESS(6) 0 -STRESS(6) -0.5*STRESS(5) -0.5*STRESS(4) -0.5*(STRESS(1)+STRESS(3))];

SIG=[STRESS(1) STRESS(4) STRESS(6);

STRESS(4) STRESS(2) STRESS(5);

STRESS(6) STRESS(5) STRESS(3)];

SHEAD=zeros(9);

SHEAD(1:3,1:3)=SIG;

SHEAD(4:6,4:6)=SIG;

SHEAD(7:9,7:9)=SIG;

EKF = BM'*(DTAN+CTAN)*BM + BG'*SHEAD*BG;

....](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-116-320.jpg)

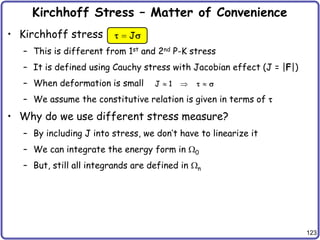

![137

Return Mapping in Principal Stress Space

• Principal stress vector

• Logarithmic elastic principal strain vector

• Free energy for J2 plasticity

• Constitutive relation in principal space

– Linear relation between principal Kirchhoff stress and logarithmic

elastic principal strain

T

p p1 p2 p3

[ , , ]

T T

1 2 3 1 2 3

[e e e ] [log log log ]

e

2 2 2 2

1

1 2 3 1 2 3

2

ˆ

( , ) [e e e ] [e e e ] K( )

e x x

e

p

c e

e

e 2

dev

3

ˆ ˆ

( ) 2

c 1 1 1

T

ˆ [1, 1, 1]

1 1

dev 3

ˆ ˆ

( )

1 1 1 1

Good for large elastic strain](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-137-320.jpg)

![139

Return Mapping in Principal Stress Space cont.

• Plastic evolution in principal stress space

– Fundamentally the same with classical plasticity: Classical

plasticity [s(6×1) and C(6×6)], but here [p(3×1) and ce(3×3)]

– During the plastic evolution, the principal direction remains

constant (fixed current configuration)

– Only principal stresses change

tr e tr

p

c e

p

tr e

p p

p

f̂( , )

g

q

c

p

n 1 n

f̂( , )

g

q

q

x x

p p

ˆ ˆ

0, f( , ) 0, f( , ) 0

g g

q q

](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-139-320.jpg)

![142

Consistent Tangent Operator

• Relation b/w material and spatial tangent operators

– FirFjs: transform stress to material frame = FSFT

– FkmFln: differentiate w.r.t. E and then transform to spatial frame

• But,

• Let

• We want , but we have

S

D

E

T T

: : [ ( ) ] : : [ ( ) ] ( ) : : ( )

E D E F u F D F u F u c u

e e e e

rs

ijkl ir js km ln rsmn ir js km ln

mn

S

c F F F F D F F F F

E

ij

ijkl

kl

c

e

3

n 1 n 1 i

pi

i 1

m

c e

2

p alg e 2

dev

tr

4

4 A [ ]

g

c c N N 1 N N

e

T

w w

F F

E

e](https://image.slidesharecdn.com/chap-4feaforelastoplasticproblems-230201060657-7c6360bb/85/Chap-4-FEA-for-Elastoplastic-Problems-pptx-142-320.jpg)