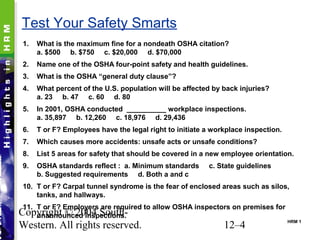

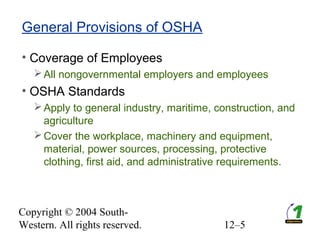

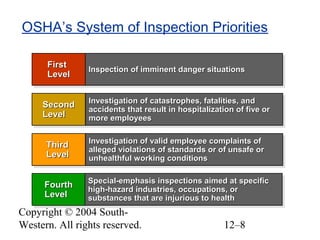

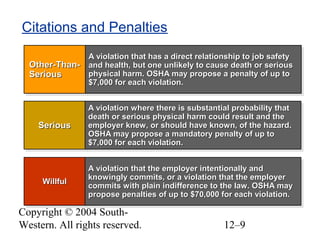

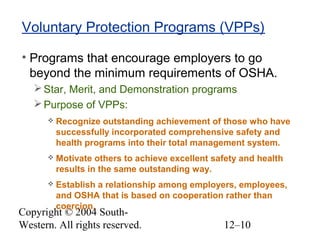

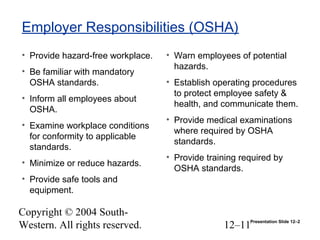

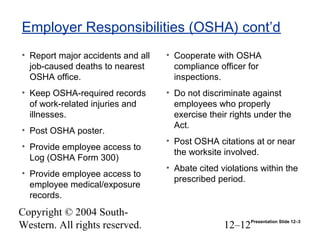

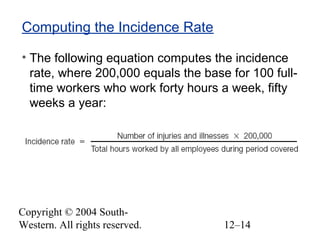

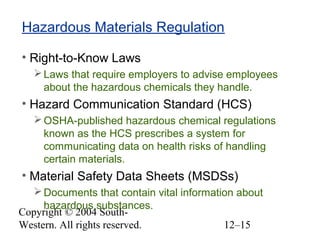

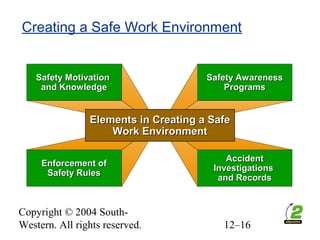

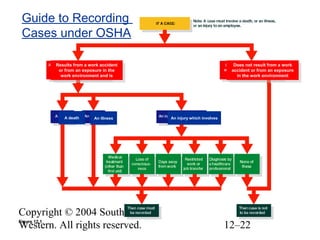

The document discusses the Occupational Safety and Health Act (OSHA) and workplace health and safety. It provides objectives for understanding OSHA provisions, employer and employee responsibilities under OSHA, and computing incidence rates. Specifically, it aims to summarize OSHA standards and guidelines, how to create a safe work environment, identify health hazards, and methods for coping with stress.