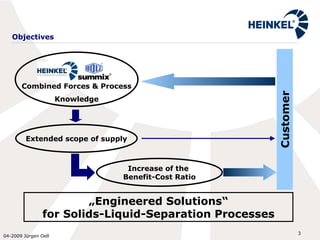

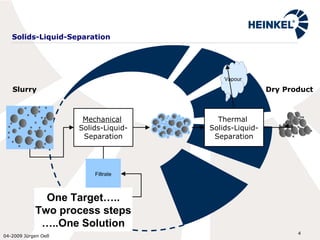

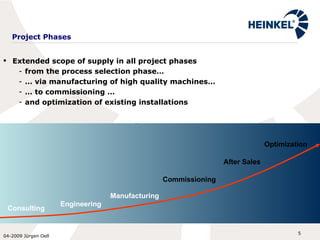

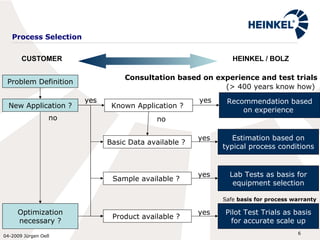

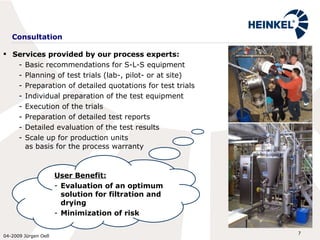

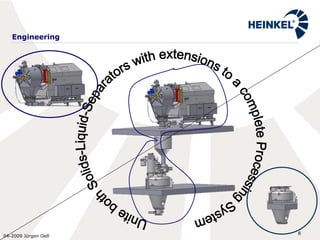

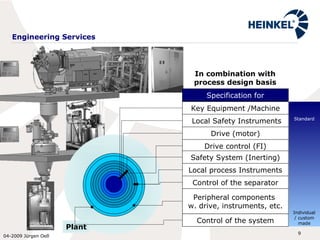

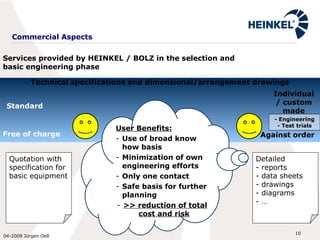

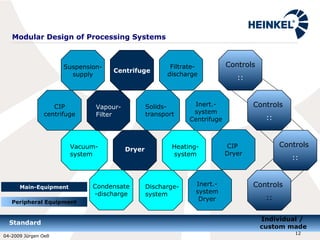

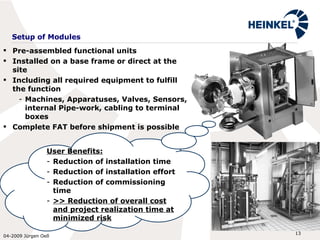

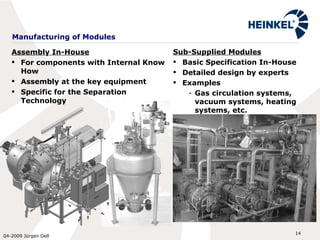

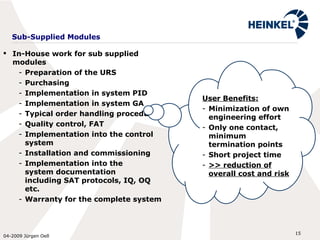

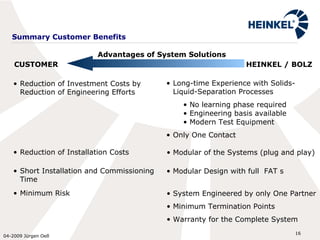

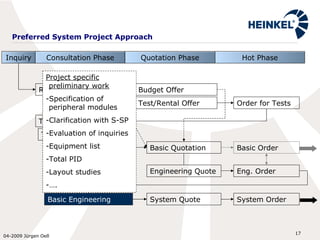

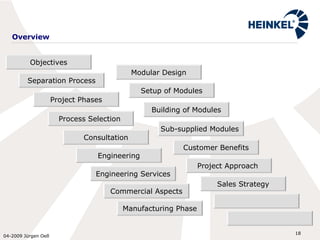

Separation Systems Engineered Solutions provides filtration and drying systems with an extended scope of supply. They offer consultation, engineering, manufacturing, commissioning, and optimization services. Their modular system design approach reduces costs and risks for customers by providing a single point of contact and minimizing engineering efforts through their extensive experience and testing facilities.