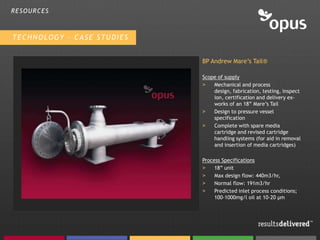

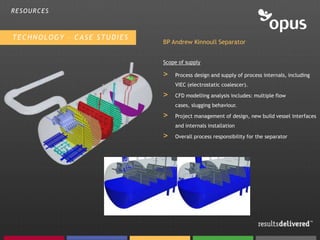

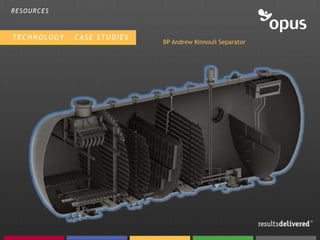

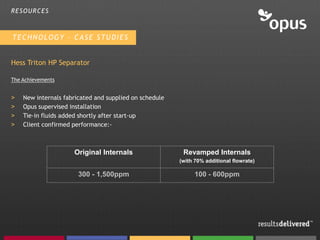

This document provides an overview of resources offered by the company, including consultancy services, technology, and environmental services. The technology section lists various oil and gas production process equipment and studies. Several case studies are then described showing applications of production separators, fluid treatment units, degassers, and hydrocyclones on offshore platforms and FPSOs. Upgrades are discussed that improved performance for various clients.