The document summarizes the optimization of a TEG dehydration unit using recent advances in technology. Three technologies were selected to decrease the capital and operating costs and weight of the unit: liquid turbochargers, pervaporation membranes, and injection of semi-lean TEG. Simulation showed liquid turbochargers reduced energy consumption by 70%. Membranes decreased reboiling energy but were very costly. Semi-lean injection reduced equipment size but required design changes. The hybrid process doubled capital costs from the conventional design due to high membrane costs. Further research is needed to lower membrane prices and make them economically viable.

![2 1. Introduction and Project Charter

Natural gas that comes out of a well is saturated water. It often also contains other compounds

such as Hydrogen Sulfide, souring the gas. These components must be removed following the scheme

of figure 1.1. Moreover, several crucial reasons why water need to be taken out are presented below:

• It can trigger the production of hydrates and of crystals. When transport of the natural gas is

lead through long pipes, the chance of clogging becomes high and the removal of these plugs is

expensive.

• Water can cause corrosion to the pipelines.

• It can cause slugging flow conditions which increases the pressure drop over the pipeline.

• In presence of water, the heating value of gas decreases radically. [1] [2] [3]

One of the most used dehydration processes is Glycol dehydration, with about 30,000 units in

operation in the USA alone. This method can be performed with any Glycol solvent, but the mostly

tri-ethylene glycol (TEG) is used. This process started to be used in the 1970’s and has not changed

much since. In a contactor column of perforated trays or a packing, the wet gas stream and the TEG

stream will meet in counter current. After absorption the TEG rich in water goes to a regenerator,

where the water is taken out in a still column. The pressure difference between these two processes

is usually very high, going from 160-170 bar to atmospheric.

As mentioned before, the dehydration of Natural Gas using TEG has been used for over 40 years.

Not much has changed to the way this process works over all the years. However, with a growing

interest in process intensification and many developments in this field, it could be possible to decrease

the size of the TEG unit while maintaining or even increasing the effectiveness.

Parts of the system in which a potential weight loss can be significant are the TEG inventory and

the size of the regeneration system. Examples of techniques that will be looked into are pervaporation

membranes and microwave heating, among others, having the potential to reduce the size and price

of the unit significantly.

1.2. Objectives

The assignment, provided by Frames group, is to find and design a new dehydration unit by introducing

new innovations in order to lower the CAPEX, OPEX and weight of the conventional TEG dehydration

unit for an offshore platform using recent advances in science.

Therefore, the first task that needs to be done is the definition of the conventional process.Then,

the CAPEX, OPEX and weight of it will be set as benchmark. In the next stage, improvements will be

proposed and their impact will be estimated especially in terms of CAPEX, OPEX and weight. Finally,

conclusions and remarks will be posed about the proposed design of the unit.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-10-320.jpg)

![4 1. Introduction and Project Charter

1.3.3. Plant capacity and location

The capacity of the plant will be 380617 kg/h of wet natural gas which comes as feed stream to the

unit. Once the mass balance and streams study is completed, it results that the plant will produce

around 340000 kg/h of dry gas which includes small amount of water (24 mg/Sm3) coming out of the

unit. This means that 2594 kg/h (purity wt 99.4%) of lean TEG are needed to absorb the 131 kg/h of

water which needs to be removed. Given that the expected results are subject to 10% of turn down,

the capacity of the plant must hold these fluctuations too.

Figure 1.3: Norwegian geographical map,

green areas are open for petroleum and gas

platforms, red and orange are considered to

be opened for industrial uses [4]

The TEG dehydration unit will be located in the

European country Norway, specifically in an offshore

platform of its coasts situated in the North Sea. As

shown in figure 1.3 the whole western part of the Nor-

wegian coast in the North Sea is open for petroleum

and gas industry.

Norway is the world’s second biggest exporter of

natural gas and the fifth biggest exporter of oil, at

the same trying to become one of the world’s most

environmentally friendly industries in this field. This

country has high pollution standards and there is con-

tinued work on reducing emissions and avoiding ac-

cidents or spills. This sector is vital for the country’s

economy, representing about 25% of the gross do-

mestic product, 30% of the state income, more than

50% of export earnings and providing approximately

250,000 jobs, directly and indirectly. In addition, this

industry not only helps to its own wealth fare, but also

is a very important contributor for the innovation and

technological development in other related sectors.[5]

Norway has been producing gas for about 40 years,

but at this moment its production has lowered till 20%

of its highest peak. The development in natural gas

exports from facilities on the Norwegian Continental

Shelf (NCS) has drastically decreased as reported by

the Norwegian Petroleum Directorate (NPD) from 2006 to 2013. [6] The natural gas extraction has

reduced total sales gas volumes with around 4% relative to what was exported from the production

installations. In spite of this trend, optimism is present because of the discovery of new reserves, even

in mature areas. Together, these will amount to 400-600 million barrels of oil equivalents allowing new

projects in Norwegian waters in the next 10-15 years.

Although the production costs are relatively high in the North sea, the quality of the oil and gas,

the political stability of the region, and the close proximity to important markets in western Europe has

made it an important oil and gas producing region. The largest natural gas field in the North Sea, the

Troll gas field, lies in the Norwegian trench dropping over 300 metres. This required the construction

of the enormous Troll A platform to access it. Besides it, in the Ekofisk oil field, the Statfjord platform

is also notable as it was the cause of the first pipeline to span the Norwegian trench.

The average air temperature in summer is 17°C while it is 6°C during the winter. The average

temperatures have been trending higher since 1988, which has been attributed to climate change. Air

temperatures in January range on average between 0 to 4°C and in July between 13 to 18°C. The

salinity averages between 34 to 35 grams of salt per litre of water, having its highest variability where

there is fresh water inflow, such as at the Rhine and Elbe estuaries, the Baltic Sea exit and along the

coast of Norway.

With growing demand for improved gas technology, this field is suitable to process intensification.

As stated in the Petroleum White Paper, the Government has confirmed the strategy for developing the

petroleum and gas with a proactive, parallel commitment to increased recovery from production fields,

developing commercial/profitable discoveries, exploring in open acreage and opening up new areas.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-12-320.jpg)

![1.4. Database 5

1.4. Database

In this section of the project, all relevant data of the compounds involved is tabulated. This is also the

data that is used in the simulations.

1.4.1. Component list

In this project only three different species are observed. TEG, natural gas and water. The natural gas

coming out of the well consist of the components shown in table 1.2. The properties of the different

species are discussed later in this section.

Table 1.2: List of components in Natural gas provided by Frames

Component name Mol. %

H O @saturation

N 0.18

CO 3.58

Methane (CH ) 86.49

Ethane (C H ) 5.33

Propane (C H ) 2.18

i-Butane (C H ) 0.49

n-Butane (C H ) 0.89

i-Pentane (C H ) 0.25

n-Pentane (C H ) 0.24

C + 0.33

1.4.2. Component and thermodynamic properties

Table 1.3: Component and thermodynamic properties of Triethylene Glycol and water

Property Value TEG Value water

Molecular Formula C H O H O

Molecular Weight 150.17kg/kmol [7] 18 kg/kmol

Boiling Point 285 °C[8] @ 1 atm 100 °C @1 atm

Melting Point -7 °C [8] 0 °C @ 1 atm

Density 1127.4 m @ 15 °C [8] 998.3 kg/m @ 200 °C[9]

Viscosity 0.00478 Pa.s @ 200 °C[8] 0.001003 Pa.s @ 200 °C [9]

Vapour Pressure <0.001 kPa [7] 2337 Pa @ 200 °C [9]

Heat of Vaporisation 61.04 kJ/mol @ 1 atm [8] 2257 kJ/kg @ 1 atm[10]

Triethylene Glycol (TEG)

TEG is the water absorbing species in this system. It is a colorless, viscous liquid, well known for

its hygroscopic properties and its ability for dehumidifying fluids. It is used especially as a desiccant

for dehydration of Natural gas. It will however degrade when the temperature rises above 204 °C,

this makes good temperature control important and hotspots should be avoided. It’s thermodynamic

properties can be found in table 1.3.

Water

Water is the universal solvent. Industrially, water has been used for many purposes, especially for

cooling. The natural gas obtained from wells is saturated with water which needs to be removed due](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-13-320.jpg)

![6 1. Introduction and Project Charter

to the reasons mentioned in section 1. The thermodynamic properties of water are also listed in table

1.3

Natural gas

Table 1.4: Component and thermodynamic properties of natural gas

Property Value natural gas

Molecular Formula 86.49% CH

Molecular Weight 19.5 kg/kmol (Frames specified)

Density [11] 0.79-0.9 kg/m @ STP

Net Heating Value [11] 46054800 J/kg (11000 kcal/kg)

Natural gas, consisting of predominantly Methane, is a hydrocarbon gas formed due to fossilization

of buried plants and animals. For these species to become natural gas they were below the earths

surface for over a thousand years. It is a non-renewable source of energy and is typically used for

heating (industrial) and cooking (domestic). Some of the properties of Natural gas are given in table

1.4. The specification of the natural gas that comes from the specific well in Norway are given in table

1.2.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-14-320.jpg)

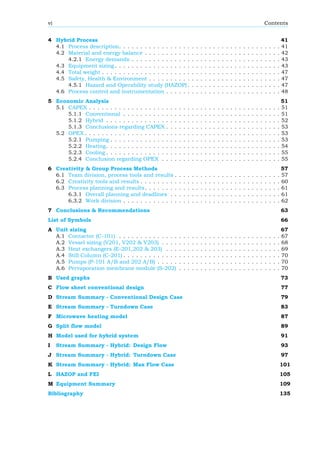

![8 2. Conventional Process

2.1.1. Contactor (C101)

Streams in: Wet gas <102>, Lean TEG <103>. Streams out: Dry gas, Rich TEG <104>.

The absorption column, also called the contactor in this process, is the main piece of equipment of

a TEG dehydration process. In the absorption process, a liquid is used to contact wet gas and remove

the water vapor. With absorption, the water content in the gas stream is dissolved in a relatively pure

liquid solvent stream. To achieve this it is necessary to create a surface area as large as possible

between the two phases. This can be achieved using several pieces of internal equipment, such as:

• Division into trays.

• Random packing.

• Structured packing.

Trays

Figure 2.2: Typical

bubble cap plate

column for TEG

dehydration

contractor[12]

One way to achieve a high surface area between the two phases is to divide

the column into trays as displayed in figure 2.2. Gas flows from below each tray

through bubble caps, which ensures the formation of small bubbles of gas. Each

tray is filled with liquid glycol which accumulates due to an overflow wall at the

tray. The small gas bubbles provide a large surface area which is needed for

the mass transfer. Because the bubbles rise relatively fast the contacting time is

short. Hence equilibrium is not reached. Therefore several trays are needed to

reach the dehydration specifications for gas transport, usually 6 to 20 trays are

used, spaced approximately 61 cm apart.[13]

Random packing

Various types of random packing are also used in glycol contactors to achieve a

high surface area for mass transfer. The total height of the packing in the vessel

can be calculated from the number of theoretical stages used in the design.

Typically suppliers of the packings have correlations for packing height needed

per theoretical stage.

Structured Packing

Structured packing is to load the column with arrangements of steel internals

over which the glycol flows downward. The gas flows upward through the pack-

ing and has a large contact area with the glycol. This provides a very efficient way for mass transfer to

occur and is therefore used the most throughout offshore dehydration[13]. Just as in random packing,

suppliers have developed a relationship between the packing height needed and the number of theo-

retical stages. When designing the column it is essential that the glycol is distributed evenly over the

top of the packing, to ensure a good mass transfer area. A typical structured packing is displayed in

figure 2.3.

Usually a structured packing is used as it provides the best mass transfer surface area compared to

random packing and tray columns. A larger surface area provides a better mass transfer and therefore

a smaller column. The wet gas is fed at the bottom of the column and dry gas leaves the top. At the

top the lean glycol is fed and the rich glycol will be returned below the wet gas feed.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-16-320.jpg)

![2.1. Process description 9

Figure 2.3: Typical structured packing used in the industry[14]

2.1.2. Flash (V201)

Streams in: From HX (E201) <203>, Streams out: Drain, OVHD & to filters (S201) <205>.

(The stream numbers depicted refer to Figure C.1 in Appendix C)

Due to the high pressure used in the contactor some gas is physically dissolved in the liquid glycol. The

higher the pressure in the contactor, the more gas dissolves in the liquid. A flash tank is needed to take

that portion of gas out of the liquid. The liquid first gets heated in the still column and afterwards it is

depressurised in the flash tank. With these changes the gases evolve from the glycol in the gas tank.

It is designed as a three-phase separator to help remove any condensate in the liquid and therefore

increase the lifetime of the downstream filters.

2.1.3. Filters (S201)

Streams in: From flash (V201) <205>, Streams out: to HX (E202) <206>.

To prevent clogging and optimal conditions for glycol it is very important to keep the glycol as clean

as possible. Impurities might also cause foaming in the still or contactor. Therefore filters are installed

to take out impurities. Particle filter are usually in operation all the time to take out any condensate in

the liquid. Carbon filters can be bypassed most of the time and will be installed on stream, if there are

no hydrocarbons in the stream.

2.1.4. Reboiler (V202) & Still column (C201)

Streams in: From HX (E202) <207> & OVHD, Streams out: to OVHD & to Surge <208>.

The rich glycol is preheated through heat exchange with the lean glycol leaving the reboiler and

enters the top of the still column. By taking the temperature near the boiling point of glycol the glycol

release the absorbed water and any other compounds until a purity of 99.4% is reached. The reboiler

is heated through a fire tube in which natural gas, sometimes from the flash, is burned. The reboiler

and the still run at near atmospheric pressures.

2.1.5. Stripping column (C202)

Streams in: From reboiler (V202), Streams out: To Surge (V203).

A stripping column is inserted between the reboiler and surge to achieve the highest purity possible.

As stripping gas the gas phase from the flash vessel is used. A part of the water will dissolve in the

gas phase and be taken out to overhead treatment. The opposite happens from what is happening in

the contactor.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-17-320.jpg)

![10 2. Conventional Process

2.1.6. Surge (V203)

Streams in: From Stripping (C202), Streams out: To booster pump (P201) <210>.

Due to the fluctuations in the gas feed, the circulation might not always be even. A surge drum is

installed to allow for these fluctuations and to achieve a constant recirculation of TEG. An additional

benefit is the fact that it can be used as a check to see if everything is still working correctly. When

the level is significant lower then the needed of the vessel either a leak or holdup is present in the

system.

2.2. Mass and energy balance

The inlet wet Natural gas flow for the design case is given to be 380617 kg/hr at 156.5 bar(a) and 35 °C

, the outlet dry gas water fraction and the glycol loses must be lower then 24 mg/Sm , as described in

Table 1.1. From the above information, the quantity of water required to be removed in the design case

and in the turndown case were calculated. For systematic design of the Dehydration unit,a step-wise

method given by Campbell [15] was used. It consists of following steps:

• Calculation of TEG concentration: The minimum concentration of lean TEG required for dehy-

dration of natural gas was calculated by first estimating the dew point of the outlet dry gas at

given conditions from the water content in natural gas v/s water dew point graph available in

[15] and figure B.2. From the calculated dew point, the concentration of lean TEG required was

calculated from the equilibrium dew point v/s inlet gas temperature graph available in [15] and

figure B.1.From this procedure, we find that the minimum concentration of the lean TEG required

for our case is 99.2% wt.

• Calculation of lean TEG circulation rate: From the knowledge of the water content in and targeted

water content out of the contactor, the TEG circulation rate was calculated by considering a ratio

20 kg TEG/ kg water removed for a number of theoretical stages of N=1.5. This ratio was agreed

upon during the BOD meeting with Frames. The number of stages were chosen taking into

account that most TEG contactors work with 6 actual trays (tray efficiency is considered to be

0.25). The circulation rate for TEG was calculated to be around 2594 kg/hr for the design case

using this method.

In the regeneration section, the stripper column was assumed to have 3 stages.This was assumed

taking into consideration that normally the stripper column(or still column) has a lower number

of stages than the contactor.

The exhaust gas from the flash is also diverted to the stripping column so as to aid in removing water

from rich TEG.It enters the stripping column via the reboiler. Before it enters the reboiler, it is contacted

with outgoing hot TEG. For determining the pressure of the flash drum,the still top was assumed to

be at 1 bar and subsequently heat exchanger pressure drops(0.5 bar each) were added. This gave

around 4 bar operating pressure for the flash drum including some margin.

2.2.1. Simulation on Aspen Hysys

Using the background calculations as basis, the process was simulated for design and turndown case

in Aspen Hysys platform using the Glycol Package for thermodynamic calculations. This package was

chosen as it is highly recommended for systems involving dehydration of gas with TEG. The following

observations were made during simulation:

• The concentration of TEG from the regeneration increased to 99.4% on simulation and so to be

consistent, the lean TEG concentration of 99.4% was used for the complete simulation. The total

stream summary can be found in appendix C.

• It was argued that by decreasing the TEG flow proportionately for a 10% turndown would cause

cavitation in pumps and may even lead to weeping in the regeneration column. Therefore, the

lean TEG flow for the turndown case was maintained at 33% (which corresponds to 877 kg/hr).

The total stream summary can be found in appendix E.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-18-320.jpg)

![2.3. Equipment sizing 11

Energy demands

From the Aspen Hysys simulations the energy demands in pumping and heating can be found.

Table 2.1: Energy demands per type

Location Type Energy duty [kW]

P101 Electrical energy 13.4

P202 Electrical energy 0.155

Reboiler Gas heating 191.5

Total 205.055

Cooling

E203 Sea water cooler -103.5

C201 TEG Condenser -49.85

Total -153.35

Heat exchanger

E201 HX 88.5

E202 HX 168.5

2.3. Equipment sizing

All sizing presented in this section has been done following the methods described in appendix A. Every

size is reported tabulated and with equipment name. Vessel weight estimation have been preformed

using the method described in Sieder et al[16]. There it is estimated that vessel weight depends on

wall thickness of the shell, assuming the shell to be evenly thick throughout the vessel.

𝑊 = 𝜋(𝐷 + 𝑡 )(𝐿 + 0.8𝐷 )𝑡 𝜌 (2.1)

With:

L = length of vessel [m]

𝐷 = Diameter of the vessel [m]

𝜌 = Density [kg/m ]

𝑡 = Wall thickness [m]

Heat exchanger weights are estimated using Aspen Hysys. Only motor weights have been used to

estimate weight of pumps[17].

Contactor

Table 2.2: Size and weight comparison of the conventional contactor column

Name Type Diameter [m] Height [m] Wall Thickness [mm] Weight [kg]

C-101 Column 2.04 12.2 190 143135](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-19-320.jpg)

![12 2. Conventional Process

Vessels

Table 2.3: Vessel volumes

Name Type Volume Diameter Length Wall Thickness Weight

[m ] [m] [m] [mm] [kg]

V-201 Flash 0.535 0.554 2.217 6 221

V-202 Reboiler 0.465 0.529 2.117 6 202

V-203 Surge 1.16 0.719 2.875 6 371

Heat exchangers

Table 2.4: Total surface area needed per heat exchanger

Heat exchanger Surface area [m ] Weight [kg]

E-201 28.45 1253

E-202 147.0 3390

E-203 17.3 800

Basis and method of calculation of the area of heat exchanger is given in Appendix A Section

Still column

Table 2.5: Size of the conventional still column

Name Type Diameter [m] Height [m] Wall Thickness [mm] Weight [kg]

C-201 Still column 0.28 6.5 10 476

Stripping Column

Table 2.6: Size of the conventional stripping column between the reboiler and the surge

Name Type Diameter [m] Height [m] Wall Thickness [mm] Weight [kg]

C-202 Stripping column 0.25 0.5 6 32

Pumps

Table 2.7: Power requirement per pump

Pump Head [mlc] Power [kW] Weight [kg]

P-101A/B 1370 13.4 564

P-202A/B 20 0.155 22

2.4. Total weight

Adding all the weights of the separate pieces of equipment together, a total weight for the whole unit

can be estimated. In the case of the conventional process, this weight is estimated to be 150466 kg.

This is the dead weight of the unit without the weight of piping and the weight of the framework where

the unit is build.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-20-320.jpg)

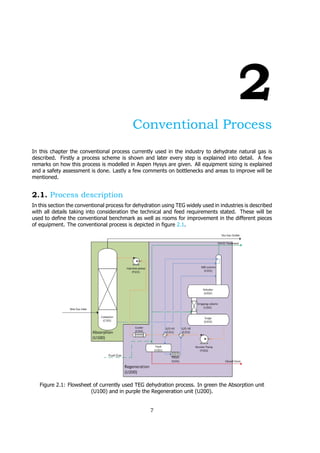

![2.5. Health, Safety & Environment 13

2.5. Health, Safety & Environment

2.5.1. Preliminary study of risks

One of the major points of the project is the analysis of risks and dangers arising from the unit. In

order to reduce them from a process design point of view the Dow’s Fire and Explosion Index (FEI)

has been performed on the absorber unit in the process. In addition, an analysis of the hazards of the

compounds present in the system as well as the possible waste generated was also carried.

The two major two flows present in the system are triethylene glycol and natural gas, described

below.

Triethylene Glycol

Figure 2.4: Safety of TEG

Some of the most important properties of triethylene glycol

(TEG) regarding safety are stated in table 2.8, where one

can appreciate that the boiling point is really high as well

as the auto-ignition temperature, reducing its risk.

Furthermore, there will be no explosion danger and

there is little toxicity danger, as shown in figure 2.4. Re-

lease of TEG into in the environment should be avoided as

much as possible, because the products of its biodegrada-

tion are more toxic than TEG itself. Moreover, in the case

of leak, the TEG should be diluted with water and absorbed into an inert material, whereas in the case

of fire, the fire should be extinguished with powder, water spray or foam. No water jet should be used.

Contact with heat sources should be avoided. Finally, direct contact with TEG should be avoided. When

in contact with eyes or digested a doctor should be contacted.

Table 2.8: List of properties for TEG [18]

Properties of TEG Value

Boiling point 285 C

Auto-ignition temperature 371 C

Flash point Closed cup 177 C

Open cup 165 C

Flammable limit Upper limit 0.9 %

Lower limit 9.2 %

LD (oral) 4700 mg/kg

TLV 10 ml/m

Natural gas

Figure 2.5: Safety of natural gas

Natural gas is highly flammable, creating the risk of explo-

sions, as can be seen in figure 2.5. Table 2.9 shows the

explosion limits of methane, which is a key component of

natural gas. A fire can not be extinguished unless the source

of the gas has been closed. So, it is advisable to let all the

gas burn up and then extinguish the fire with dry chemicals,

foam or CO .

In addition, when the gas is kept under pressure it can lead to the risk of frostbite, which occurs

when high-pressure gas is released, expanding and cooling down. This is however more dangerous

when handling liquefied gas, but in this system the natural gas remains in the gas phase. The gas is

not toxic but when released can be highly dangerous because it can cause asphyxiation by drawing

out all the oxygen. It has been found that up to concentrations of 10 000 ppm no physical changes

occur when a human is exposed. Studies have shown that there are some physical complications in

test animals who are exposed to high concentrations of methane (up to 70%) while having enough](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-21-320.jpg)

![14 2. Conventional Process

oxygen, but not much has been documented on these phenomenon and it seems unlikely that these

circumstances will occur on the plant.[19]

Table 2.9: Explosion limits of methane (key component in natural gas)[20]

Properties of methane Value

Explosion limits Lower 5%

Upper 15%

Health, Safety and Environment assessment

In conclusion, both components in the system are not extremely toxic. Good ventilation is important

to prevent a build up of natural gas in closed spaces because this can lead to asphyxiation.

Then, natural gas should not end up in the environment, hence if natural gas needs to be disposed

of, it should be burned, leading to mostly H O and CO . A danger of high concentrations of CO is that

it is heavier than oxygen and can therefor accumulate at the surface. This can cause asphyxiation.

Also, although TEG is not very toxic, the products of the degradation are. The liquid TEG needs to get

diluted with water and then absorbed into an inert and collected. When this is done, what remains can

be diluted again and disposed of through the waste water system.

Finally, the conditions at which the system operates are relatively mild. The highest temperature

reached will be around 200 °C. Only one recorded incident has been found. In may 2013 in Spain a

fire occurred after TEG was added via the TEG inlet. The TEG inlet was aimed at a hot spot and the

TEG vapor caught fire. It was only reported as a level 1 emergency shut down. [21]

If TEG or natural gas leak from the system, the chance of it reaching a hot surface or an ignition

spot should be decreased as much as possible. Another big risk comes with the high pressure in the

absorption tower. When the vessel or piping at high pressure breaks, it can result in an explosion

and both TEG and Natural gas can be released. The sudden expansion of the natural gas can cause

frostbite. Also the chance of an explosion of natural gas will increase in these conditions, resulting in

big amount of natural gas released in a very short time.

In addition to the HSE assessment, a bow tie diagram has been made, shown in figure 2.6. For this,

it was selected that the high pressure of 156.5 bar in the contactor is the most hazardous condition

present in the process and the selected top event is a rupture in the wall of the contactor. The bow tie

can be used to identify threats that increase the chance of the top event happening. It also contains

the consequences of that top event. Also barriers to decrease the treats and the consequences of the

top event are added.

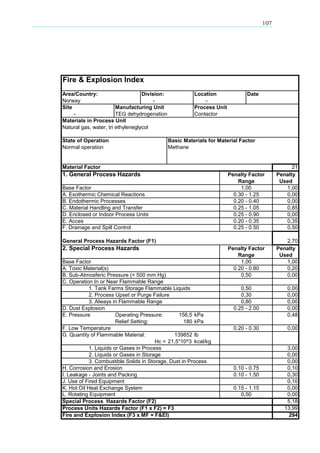

2.5.2. Dow’s Fire and Explosion Index (F&EI)

In order to classify the risk of the dehydration process, a fire and explosion index has been made. The

tabel with assigned values and the final F&EI can be found in appendix L

The two species in the system that are capable of creating a fire or explosion are TEG and natural

gas. Because natural gas exists of multiple species, the properties of methane have been used, since

the largest part of natural gas consists of this. The information needed for the F&EI is in table L.1.

For the F&EI the material with the highest Material Factor(MF) needs to be used for the calculations.

In this case this will be the natural gas because the methane has an MF of 21. Also the unit which

will be looked at needs to be specified, in this case the contactor. The species present in this unit are

natural gas, TEG and water.

Base factors

This subject is cut into multiple items. The only items which get a penalty are: Material Handling

and Transfer, Access and Drainage and Spill Control. These items get penalties because of the highly

flammable nature of natural gas, the inaccessibility of an offshore platform and the difficulty in im-](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-22-320.jpg)

![20 3. Innovation Map

Advantages of this technique are that there is no heat transfer zone so the heating occurs in the entire

volume that is being irradiated. The waves are selectively being absorbed and a rapid heating can

occur.

The dielectric component in the TEG regenerator is water, this is the species that needs to evaporate

out of the TEG. This will also be the target specie of the microwaves generating the heat, which means

that the water in the mixture can become warmer than the TEG, which will lead to faster evaporation.

TEG however has an interaction with water molecules as it contains alcohol groups. This can lead to

the TEG heating up as well. No test regarding this specific process to check if only the water heats has

been done as of now. The molar fraction of water molecules of the feed stream is 32 mol%. Regarding

this high molar concentration it can be expected that there is a lot of contact between water and glcyol

and therefor energy transfer. A different benefit is however, while there is no heat transfer area, the

total volume of TEG and water can be heated at once and uniformly.

Figure 3.1: Microwave heating[22]

Experiments showed that only heating up the liquid will not benefit the separation of the binary

mixture[22] and the stirring will also create a uniform temperature in the liquid phase which takes

away the advantages of the selective heating. However, when also the surface is irradiated with

microwaves the separation of the more volatile species is more effective than in a separation without

microwave heating. One explanation of this is that very locally high temperatures will occur, resulting

in a smaller column with fewer trays. These so called ”hot-spots” can lead to a fouling in TEG, as TEG

thermally degrades at temperatures above 210 C.[7] Discussion with professor Stankiewicz and Dr.

Guido Sturm however provided a different outlook as they mentioned new ways of heating which was

very controllable an predictable and therefor those hot-spots can be avoided.

The uniformity of microwave heating however is debatable. In literature it is described that by

absorption in the medium the intensity of the field will drop quickly. This leads to a large part of the

volume not heated and parts of the volume overly heated [23]. Dr. Guido Sturm mentioned however

that this effect can be reduced a lot, because the behaviour of microwaves can be described quite

good. By altering the field and radiation techniques these hot spots can be minimized. This is not done

on a larger scale then lab, but shows good promise.

The currents hurdles in the use of microwaves in industry are the yet unreliable scale up of the

process, which can be helped by modeling the field and design it that way. Another hurdle is the

implementation of microwave equipment into conventional chemical equipment.

3.1.3. Super-X packing

The Super X-pack packing is an innovation which is fabricated to mimic fractal structures. These fractal

structures, shown in figure 3.2, are known to enhance transfer rates, leading to a decrease in TEG

inventory. This packing could be beneficial in both the regenerator as well as in the absorber.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-28-320.jpg)

![3.1. Description of alternatives 21

Figure 3.2: Nagaoka Corp. Super-X packing

The Nagaoka International Corporation, which

developed the Super X-pack packing, made very

interesting claims with the development of this

technology. The company claimed a reduction of

the pressure drop by a factor of 3, while the pack-

ing reduced the height of the column by a factor

of 5 compared to conventional column, achieving

up to 80% energy saving [24].

However, despite these advantages, severe

operational problems were encountered, mostly

due to the packing getting clogged and fouled,

which eventually lead to the stopping of the com-

mercialisation of the packing.

3.1.4. Liquid turbochargers

A turbocharger, is an induction device used to al-

low more power to be produced by an engine of

any given size. A engine with a turbocharger can

be more efficient than a naturally aspirated en-

gine, because the turbine forces more air, and proportionately more fuel, into the combustion chamber

than atmospheric pressure alone. [25]

Applied to process engineering it can be used to transfer pressure using kinetic energy. A high-

pressure fluid or gas is used to drive a turbine which pressurises a low pressure liquid. Within TEG

dehydration it can be used to pressurise the lean glycol heading for the contactor, by transferring the

energy available in the rich Glycol.

Figure 3.3: Liquid Turbocharger [26]

As 50% of the total cost of gas refining is represented by energy costs, the addition of a turbocharger

can provide a significant cut down in operational costs. By using a liquid charger less investments

need to be done regarding pressurising the glycol, therefore a cut down in capital expenditure is also

expected. The company Energy Recovery claims an energy efficiency of up to 80%. On the other

hand, this technology reduces the degrees of freedom of the system, as it combines different streams

of the process. These Glycol powered pumps are currently sold skid mounted by companies such as

Kimray and Rotor-Tech.

3.1.5. Pervaporation membranes

This technology is itself a combination of two others. On the one hand it there is a permeation,

transport through a membrane, on the other there is evaporation, changing its phase from the liquid](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-29-320.jpg)

![22 3. Innovation Map

to the vapour phase (see figure 3.4). Therefore, the water of TEG-water mixture in our regeneration

system might be taken out using a hydrophilic membrane as a selective barrier between the liquid

phase feed and the vapour phase permeate allowing the desired molecules to diffuse through it by

vaporization.

Figure 3.4: Pervaporation membrane for dehydration

One of its main benefits is not being a pressure driven process. Instead, the driving force is due

to a higher chemical potential on the feed side than on the permeate side. The gradient in chemical

potential is then maximized by using high feed temperatures and low pressures on the permeate side

as well as combining polymer properties for membrane. [27].

By replacing distillation by the pervaporation membranes for the Glycol regeneration subsystem,

according to Pervatech company savings up to 75% on regeneration equipment and 30 to 50% reduc-

tion on energy usage can be achieved. However, membrane units, including the need for vacuum, are

currently relatively expensive. Also, if the supply contains suspended matter or dissolved salts mem-

brane pollution may be encountered. In this case, an effective pretreatment must be implemented.

e.g. filtration.[28]

3.1.6. Molecular sieves + TEG unit

Molecular sieves are usually installed in applications in which very low residual water content is required,

such as ahead of a low temperature hydrocarbon extraction process. They are suitable for drying very

sour natural gas that also contains aromatic compounds. However, heavier hydrocarbons might be

difficult to remove from the silica gel during the regeneration step. These solid compounds (silica gel

or zeolites) used as molecular sieves are prepared as round or slightly elliptical beads having a diameter

of about 4 to 6 mm. Each of these compounds has its own characteristic affinity and adsorptive capacity

for water, so a good selection is crucial in the process.[29]

While dehydration with Glycol is the most common process used to meet the water dew point

specification for sale the gas, under certain conditions solid adsorbents are also used for this purpose.

i.e. Molecular sieves are used for many offshore applications such as floaters (FPSO’s). The positive

side of molecular sieves is that they can handle wave-motions very well. The downside is the scale

and weight of the units.

A molecular sieve dehydration unit after a TEG dehydration unit, will be used for polishing and

increasing water removal efficiency. It will be able to achieve very low dew points which are required

for cryogenic plants. Additionally, molecular sieve units can also handle large flow variations as well as

higher inlet gas temperatures. However, they have higher initial capital investments, are way bigger

and heavier than comparable Glycol units.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-30-320.jpg)

![3.1. Description of alternatives 23

Figure 3.5: Molecular sieve for water adsorption

3.1.7. Addition of entrainer

Heterogeneous azeotropic distillation is a widely used technique to separate non-ideal mixtures. The

procedure is incorporating a new component (entrainer) in the system such as toluene or octane. The

entrainer will form a heterogeneous azeotrope with water of the initial mixture. Then, the azeotrope

having minimum boiling point goes to a decanter and splits in two liquid phases. The stream rich in

the entrainer is recycled back to the azeotropic column and the other water rich goes to treatment.

This azeotropic distillation has various advantages such as a high efficiency of separation, low reflux

ratio and a reduced heat energy and it can be a suitable solution for the regeneration part. However,

adding a third component always increases the complexity of the separation. The gas-liquid composition

distribution in the column is much more complicated than that in the usual one, and a stable operation

of a distillation column is very difficult. It is also necessary to add more pieces of equipment for the

entrainer recovery, resulting in a bigger and heavier unit.[30] [31]

3.1.8. Vacuum operation in still column

At vacuum conditions the concentration of TEG obtained in the still column will be higher for the

same reboiler temperature used for atmospheric operation, as the boiling point decreases for the same

rich solvent. Another possibility of vacuum operation, if not so pure TEG is required, is reducing the

temperature in the reboiler. In addition, it helps extend the useful life of the system Glycol.

However, reboilers are operated under vacuum conditions in rare cases due to its complexity, vacuum

generation equipment and the fact that any air in the process may result in degradation of the TEG.

Hence, it is usually cheaper to use stripping gas. [32]

3.1.9. Rotating packed beds (HiGee)

Firstly described by Ramshaw and Mallinson[33], rotating bed reactors or HiGee (short for high gravity)

distillation, have taken a large role in offshore oil dehydration. It is used widely in China and the benefits

were readily recognized by the American market and is currently being introduced there. The European

industry however lacks behind regarding HiGee distillation.

By rotating the reactor the gravitational field increases 100-1000 times and therefore the shear flow

is enhanced. The high centrifugal speeds allows for packing with relatively higher specific surface area

and achieves order(s) of magnitude higher gas liquid throughput and possible mass-transfer rates.[34]

These factors lead to a significant reduction in size of conventional mass-transfer equipment such as

absorption and distillation towers. Ramshaw and Mallinson [33] claim achieving an up to 100-fold

reduction in equipment size. Later experimental studies however tempered these claims and found an

5-10 fold reduction in HETP [35] which is still an significant decrease in size.

The main downsides however are that moving parts are introduced which are more maintenance

sensitive than conventional techniques. The inside rotating bed has a dynamic seal, which prevents

the gas from bypassing the rotor, but compromises the reliability and longevity due to its contact with](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-31-320.jpg)

![24 3. Innovation Map

working fluid. Also, one unit can not be competent for continuous distillation owing to incapability of

feeding the rotor at radial position, equivalent to middle plate of traditional distillation column. Thus two

units of rotating bed are required for continuous distillation; one as rectifying and the other stripping.

HiGee technology can both be used in the contactor part of the process as well as the TEG regener-

ation. By using rotating bed reactors the size and weight of the contactor and still column and therefor

the total unit can decrease significantly.

Figure 3.6: HiGee distillation: (a) RPB integrated with reboiler and condenser; (b) RPB with off center

feed and integrated with reboiler [34]

3.2. Selection of alternatives

In this case, from stated above it is decided to gather the information in a way such that it can be

compiled and presented in a consistent, high visualization chart, showing the strengths and weaknesses

of each application for each criteria, accompanied by focused comments from the team, resulting in

the selection table 3.1.

There is no such thing as one solution which fits all requirements when it comes to chemical solvent

recycling or dehydration. Solutions are therefore necessarily hybrid in nature where a combination

of traditional and improved technologies is used. Each technology provides a part of the separation

required within a customized sequence and overall methodology and further research must be carried

out in terms of OPEX, CAPEX and weight to determine the improvement of the alternative.

However, there are already five possible technologies that will be rejected directly. The first one will

be Super-X packing, because it is not being commercialized anymore, avoiding any possibility of its real

implementation. Secondly, the hybrid molecular sieve plus TEG unit is not going to be implemented

due to its weight and scale makes it not suitable for platform location, which is one of the requisites.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-32-320.jpg)

![26 3. Innovation Map

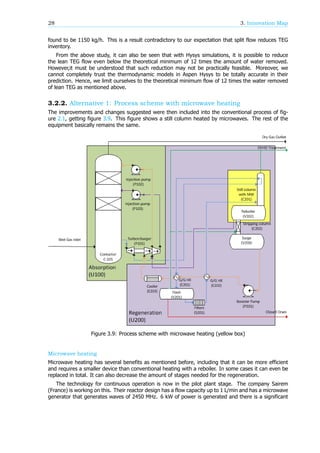

Figure 3.7: Process scheme with turbocharger and semi-lean TEG split flow injection, shown in yellow

boxes

Turbochargers

The size, and therefore weight, of the injection pump system can be lowered by using a turbocharger,

because as mentioned, this device interchanges the energy of a high pressure stream with a low

pressure one. This can also decrease the total energy needed for the pumps as well as the number of

them.

The total operational costs for pumping, assuming a total cost of 10 ct €per kWh[36], is 1.34 €per

hour [37]. Assuming 24/7 operation the total costs per year of this pump will be € 11.738. Using

calculation tools provided by Energy Recovery©a recovery of 70 % of energy can be achieved. This

will result in a evenly large reduction of operational costs. So a reduction of € 8.216 on a yearly basis

can be achieved. Not only that, also a reduction of 9.38 kW is achieved at the pumping section. This

leads to a reduction of approximately 79.866 kg CO which is released on a yearly basis[38]. The

total energy requirement for the plant is 205 kW. By adding a liquid turbocharger into the conventional

process a reduction of 4,6 % can be achieved without increasing the capital expenses which will be a

real benefit.

Split Flow injection

This alternative is studied with an intention of reducing the TEG inventory in the recirculation system.

Following is the discussion of the study.

The incoming lean TEG is fed to the top-most stage of the contactor. As per the design of the

conventional process in section 2.2, the contactor has 6 theoretical stages, therefore, it is possible to

study injection of TEG ranging from 2 to 6 splits, simultaneously varying the percentage of flow flowing

through each split branch. However, it should be noted that while injections with 2 and 3 splits can

be studied extensively for symmetric arrangements between theoretical plates, for higher number of

splits(eg:4-6) there would be too many combinations possible.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-34-320.jpg)

![3.2. Selection of alternatives 29

part of the design devoted to cooling. The unit is a metallic vessel which assures pressure containment

and allows for fast thermal transfer.[39]

However, heating volatile, often flammable organic solvents, under well-controlled conditions is

not trivial on the large scale, but it can be done. Lastly, another Sairem 915 MHz batch reactor

was changed in the strategy to microwave scale-up through the use of a different wavelength, since

penetration depths, dielectric constants and loss factors vary with wave length as well as solvent nature

and temperature. In this case, the energy savings were due to a decrease in heating time and not in

energy efficiency, because normal household microwaves (central component of any microwave device)

has an efficiency of 50-65% transforming electricity into electromagnetic irradiation[40]. However dr.

Guido Sturm of TU Delft, a expert in microwave heating, mentioned an efficiency off up to 80 %.

Overall, there are reasons to think that together with the use of the stripping technique for glycol

regeneration, with a gas normally flowing upward counter currently to the descending liquid TEG, the

unit can achieve the requirements and reductions proposed. Depending on the stripping agent used,

i.e. outlet gas from the flash (V201), water, hydrocarbons, or both are absorbed from the glycol into

the stripping gas, thus regenerating the glycol for reuse in dehydrating the natural gas. But the reality

is that these processes produce an additional gaseous or aqueous waste stream that requires off-site

attention such as incineration, disposal, or further treatment.

An attempt has been made to model microwave in Aspen Hysys, but a working model is has not yet

been achieved. The column is split into three stages, modeled as flashes and a condenser and reboiler

part. At each stage a specific temperature is set, as is used with microwave distillation. These are all

separately heated. The feed enters the column at the middle stage, this because it gave the lowest

energy use. This model however leads to very high and fluctuating energy demands per stage. Three

different settings were used. Firstly the natural gradient occurring in the still column has been taken.

Secondly a linear decrease between the top and bottom stage has been tested and lastly the inverse

of the natural gradient is tested. This is displayed in table 3.2 and the model used is added in appendix

F.1.

Table 3.2: Energy demands from the different setting of the model described in appendix F.1

Setting 1 Setting 2

Stage

Set

Temperature (C)

Energy

Demand (kW)

Set

Temperature (C)

Energy

Demand (kW)

Condenser 97 -17.05 97 -6004

3 99.26 -162.6 125 5999

2 101.9 -16230 150 -30.85

1 150.7 16370 175 92.66

Reboiler 204 192.8 204 87.83

Setting 3 Conventional

Stage

Set

Temperature (C)

Energy

Demand (kW)

Set

Temperature (C)

Energy

Demand (kW)

Condenser 97 -7139 97 -49.85

3 145 7136 - -

2 165 32.69 - -

1 185 63.91 - -

Reboiler 204 55.17 204 191.5

As this model did not achieve realistic values different professionals in the field of modeling mi-

crowave heated column were contacted. From these conversations, it became apparent that, as this

is a very young field of research no real simulation models are achieved as for now.

The main fields in which microwave heated columns are used are pharmaceutical and food process-

ing technologies. Outside of these fields the benefits have not been sufficient enough to take the risk

of entering a new technology. To estimate the costs, the energy needed by a conventional still column

is used.

When designing the new column a few constraints should be kept in mind however. No magnetic](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-37-320.jpg)

![3.2. Selection of alternatives 31

Figure 3.10: Process scheme with pervaporation membranes (yellow box)

For a specific organic mixture (in this case TEG with water) one has to test to determine selectivity

and fluxes during the process of dehydration, because the binding force of TEG to water is high, so

fluxes will be lower compared to some other organics e.g. ethanol or IPA. In addition, it is more

difficult to dehydrate to such low water concentrations. Then a preliminary study of different types of

membranes was carried out to find out these fluxes on basis of the conventional process outlet vapour

stream from the flash.

First of all, apart from company claims, a paper was found which states that with commercial silica

membrane modules of the company Pervatech, if a feed of 0.054 wt water, 0.936 wt TEG and 0.005

wt Toluene and 0.005 wt Hexane at 150 °C, a 99.99+% wt of water purity in the permeate can be

achieved, at an average flux of 0.255 kg/m ·h [41].

In addition, an experiment performed to determine the water flux of a zeolite membrane module

from Mitsui USA was tested at 100 °C with a TEG mixture containing 5% wt water resulting in 0.13

kg/m ·h as permeate.

Other sources say that 95% wt water purity can be achieved with NaA zeolite membranes exhibiting

high separation performance and fluxes of 0.5 kg/m ·h for 5% wt feed water content at 120 °C. [42]

Also, a realistic research with improved membranes such as Sulfonated Poly-ether-ether Ketone

(SPEEK) was carried, resulting in only 98% of water purity the permeate side with 5% wt water content

in the feed at 32 °C and flux of 0.2 kg/m ·h as depicted in Huang et al (2002) [43].

In other words, in order to estimate the area required for a complete separation we carried this

analysis. It means roughly, avoiding pressure drops, no TEG losses in permeate, constant flux, 100%

water permeation and no membrane size limitation, that if our stream of 1657 kg/h (0.0033 wt others,](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-39-320.jpg)

![3.2. Selection of alternatives 33

more than the minimum required in the design case.

Table 3.3: Results of membrane area estimation

Membrane Temperature TEG in retentate water in permeate Area

type °C wt wt m

Silica 130-150 0.996 0.999 562

Zeolite 92-100 0.996 0.999 1080

NaA Zeolite 120 1.00 0.950 295

SPEEK 30-70 0.998 0.980 716

It is observed that nowadays there is a lot of research on new membranes and that most of them

fulfill the requirements for our dehydration purpose. However, there are not many supplier companies.

Examples are Sulzer Chemtech Membrane Systems, based in Heinitz, Germany; and Pervatech BV of

Enter, The Netherlands, allowing a wide range of different temperatures, modules and flows.

Furthermore, although the major component in the over head vent is water stream, as shown, this

stream may contain organic compounds, including aromatic and non-aromatic organic vapours, such

as BTEX. The emissions of them are now classified as Hazardous Air Pollutants (HAPs), and are subject

to regulations which can be better handled by these membranes.

This is, therefore, a simple and reliable method to reduce or eliminate the release of these compo-

nents, basically caused by the hydrophilic membranes which in one step both regenerate the solvent

and capture any hazardous components. Despite efforts, a cost-effective regeneration technology that

truly minimizes or eliminates HAP emissions has not yet been developed.

To finish, also a comparison of the energy consumption based on the heat requirement for evap-

oration for the removal of 1 kg water from feed mixtures can be seen in the following figure 3.12,

extracted from Huang et al (2002) [43].

It is clear in figure 3.12 that the advantage of applying pervaporation for dehydration of Glycol

becomes significant when the water content in the feed is significantly low. It should also be pointed

out that this simple comparison was based only on the theoretical energy consumption at a constant

pressure. Many other factors such as cooling of distillation, thermodynamic heat effectiveness, and

capital cost are not considered, all of which are important for the economic evaluation of these two

separation technologies.

To maintain more realism in the design, Pervatech membranes were selected for further consider-

ations. In the following study, a commercial Pervatech module PVM-080 SS 316 37×4-tube (120cm)

with 3,7 m² membrane surface was used with these assumptions and characteristics[44] [45] [46].

In the following images 3.13 and 3.14, a commercial Pervatech module is presented to get an overall

impression of the module we are using. In our case, instead of 7 elements of 4 channels each, we will

used 37 elements of 4 channels each.

• Membrane element characteristics:

– Size: 1200 x 25 mm (LxD), effective area 0,10 m² (standard). Each element has 4 channels

with 7 mm inside diameter.

– Membrane type: Hybrid silica hydrophilic membrane.

– Substrate material: α-Al2O3.

– Intermediate layer: Gamma alumina.

– Top layer: Hybrid Silica coated on inside of the support tube.

– Pore Size: 0.3–0.5 nm.

• Limits of membrane:

– Temperature: limit max. 150 °C.

– Pressure: limit max. 50 bar.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-41-320.jpg)

![36 3. Innovation Map

Figure 3.15: Feed water concentration against water flux in permeate for Ethylene Glycol- water

mixtures [41]. In red is represented extrapolated data.

• Example of calculation of number of modules estimation:

At 150 °C, the inflow for the membrane module is 1657 kg/h (0.0033 wt others, 0.912 wt TEG

and 0.0847 wt water), this is take from Aspen Hysys. For achieving the purity required after

membrane module (98.95% wt TEG) we follow:

All TEG goes to the retentate 1657 · 0.912 = 1511.18 kg/h of TEG, representing 0.9895 wt of

that stream. Therefore, the total flow of retentate is 1511.18 / 0.9895 = 1527.22 kg/h.

Hence, 1527.22 - 1511.18 = 16.04 kg of water plus other compounds. All other compounds go

to the retentate too, due to high water selectivity of the membrane, 1657·0.0033 = 5.47 kg/h

of other compounds(BTEX etc.). 16.04 - 5.47 = 10.57 kg/h of water goes into the retentate,

representing 10.57/1527.22 = 0.0069 wt water purity in that stream.

If 1657·0.0847 = 140.35 kg/h of water is fed, 140.35 - 10.57 = 129.8 kg/h is in the permeate

with 1.00 wt water purity.

At the entrance of the module, the water content in TEG is 0.085 wt, which represents a flux

of 0.612 kg/m ·h, while at the exit of the module the water content is the required 0.007 wt

of water in TEG, which gives a flux of 0.075 kg/m ·h. Therefore, doing an logarithmic average](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-44-320.jpg)

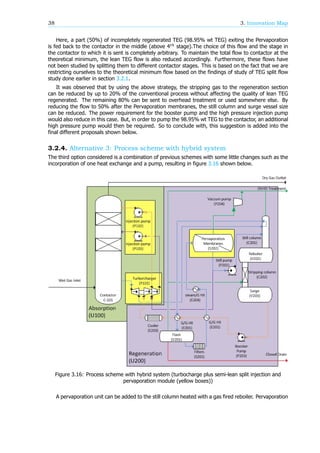

![4.3. Equipment sizing 43

4.2.1. Energy demands

All calculations are from Aspen Hysys. For the liquid turbocharger an energy recovery of 50 % is

assumed as explained earlier.

Pumping

Table 4.3: Pump duties for the hybrid system

Type Head [mLc] Power [kW]

P-102 A/B 692.9 2.04

P-103 A/B 758.2 2.17

P-201 A/B 7.9 0.027

P-202 A/B 15.5 0.045

P-203 A/B - 49

Heating

Table 4.4: Heating duties for the hybrid system

Name Type Power [kW]

E204 Steam 61.31

V202 Gas fired 35.56

Cooling

Table 4.5: Cooling duties for the hybrid system

Name Type Power [kW]

E203 Sea water 11.37

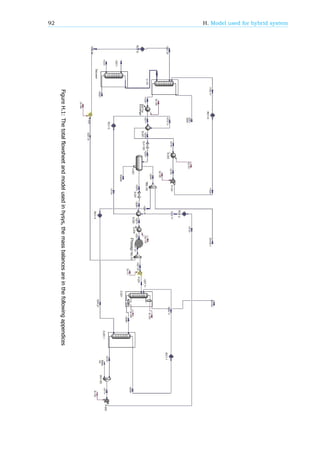

4.3. Equipment sizing

Equipment sizing has been done for all the pieces of equipment mentioned in figure 4.1 and 4.2.

Also, as requested in the assignment for this course, a total equipment summary is added in the last

appendix, Appendix M.

All sizing has been done following the methods described in appendix A. All determined sizes are

reported and tabulated. Sizes of similar kinds of equipment related the conventional process, if present,

are also reported.

Furthermore, in this case also weight of each equipment is included in order to get a good compar-

ison between conventional and hybryd units.

Vessel weight estimation have been preformed using the method described in Sieder et al[16].

There, it is estimated that vessel weight depends on wall thickness of the shell, assuming the shell to

be evenly thick throughout the vessel with equation 2.1. It was decided also to take the pervaporation

membrane unit as a set of vessel modules.

Finally, heat exchanger weights are estimated using Aspen Hysys, whereas only motor weights have

been used to estimate weight of pumps.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-51-320.jpg)

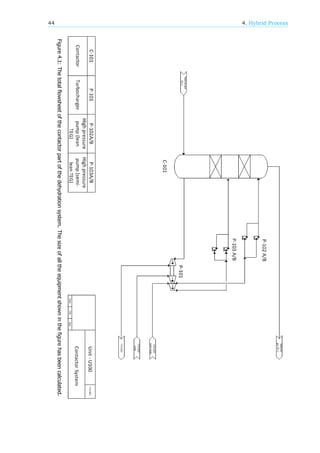

![46 4. Hybrid Process

Contactor (C-101)

The height of the column in the hybrid system is assumed to be the same as the conventional. This

is because the estimation has been done with trays which later on will be packed. There is significant

space between packing levels for an additional sparger so here there is no gain nor a loss in size.

Table 4.6: Size and weight comparison of both conventional and hybrid contactor column

Type Diameter [m] Height [m] Thickness [mm] Weight [kg]

Conventional 2.04 12.19 190 143135

Hybrid 2.04 12.19 190 143135

Vessel sizing (V201, V202 & V203)

Table 4.7: Vessel volumes

Vessel Type Volume Diameter Length Thickness Weight

[m ] [m] [m] [mm] [kg]

Flash (V-201) Conventional 0.535 0.554 2.217 6 220

Hybrid 0.313 0.46 1.85 6 154

Reboiler (V-202) Conventional 0.465 0.529 2.117 6 201

Hybrid 0.132 0.347 1.392 6 87.6

Surge (V-203) Conventional 1.16 0.719 2.875 6 370

Hybrid 0.342 0.476 1.906 6 164

Still column (C-201)

Table 4.8: Size and weight comparison of both conventional and hybrid still column

Type Diameter [m] Height [m] Thickness [mm] Weight [kg]

Conventional 0.28 6.5 10 476

Hybrid 0.145 6 13 310

Pervaporation membranes (S-202)

For complete detailed calculations see appendix A. In this case, due to the uncertainty of size and

weight, all the results have a 50% of security factor with following assumptions:

• The width and height of the unit were calculated, then multiplied by 1.5 to include space for

maintenance and pipes and finally normalized into round dimensions.

• The length was taken equal as commercial Pervatech PVM-094 SS 316 7×4-tube module with 0,7

m², because the membranes used inside for both are the same.

• The total size of the unit was calculated as rectangular set of 14x10 modules (WxH) of 1.402 m

length each, supposing there is no space limitation.

• For the weight, each module was considered a cylindrical vessel. Then a factor of 1.5 was included

for accounting the weight of internal and membranes inside it.

The results for the pervaporation unit are displayed in the following tables 4.9 and 4.10

Pumps (P-101, P-102 A/B, P-103 A/B, P-201 A/B, P-202 A/B)

In the hybrid system two new pumps are added and also a liquid turbocharger, or Glycol pump (P-

101), is considered to be a pump. The first pump P-103 is added to injection the TEG straight from](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-54-320.jpg)

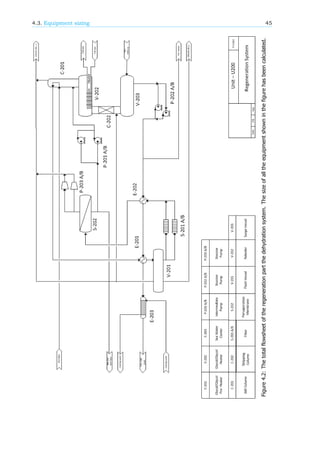

![4.4. Total weight 47

Table 4.9: Pervaporation membrane module size and weight

Module Type Flange Diameter Length Thickness Weight

[m] [m] [m] [mm] [kg]

Pervap. memb. Hybrid 0.302 0.260 1.405 6 97

Table 4.10: Pervaporation membrane unit size and weight

Unit Type Modules Width Length Height Weight

[Nr] [m] [m] [m] [kg]

Pervap. (S-202) Hybrid 138 7 1.405 5 13386

the pervaporation membranes. The other added pump, P-201, is used to transport the TEG from the

pervaporation membranes to the still column. The duties of all the pumps are in table 4.11. The duties

of P-102 & P-103 can be lowered however due to the addition of a liquid turbocharger. This will be

discussed further in 5.2.1.

Table 4.11: Pump duties for the hybrid system

Type Head [mLc] Power [kW] Weight [kg]

P-102 A/B 692 2.04 88

P-103 A/B 758.2 2.17 88

P-201 A/B 7.9 0.027 22

P-202 A/B 15.5 0.045 22

P-203 A/B - 49 1666

4.4. Total weight

The total dead weight of the new hybrid system is 161,086 kg. This is calculated by adding all different

weights together. The conventional process had a total weight of 150,433 kg. This means the total

weight of the process increased with the introduction of the new innovations. The biggest differences

can be seen in the introduction of pervaporation membranes. The introduction of the membranes did

not cut down the weight of the still column enough to also cut down on the total weight of the system

even though the weight of the reboiler is reduced with more then half. The split flow injection however

helped a great deal, it sized down all equipment after the split.

4.5. Safety, Health & Environment

In the proposed hybrid system the species present are still the same as in the conventional process

and therefore safety, health and environmentally aspects can be taken as equal as in the conventional

unit.

However, the only things that did change and can have an effect on the risk and hazard of this

system are for instance the vacuum present with the pervaporation membranes unit. Also extra pumps

have been added such as injection pump or vacuum pump.

Finally, there are now two inlet points of TEG into the contactor column instead of only one, which

brings an extra risk of leaking and malfunctioning of joints.

Furthermore, in the next subsection a HAZOP analysis will be conducted in order to select and

evaluate problems that may represent future dangers to workers or pieces of equipment, or prevent

efficient operation.

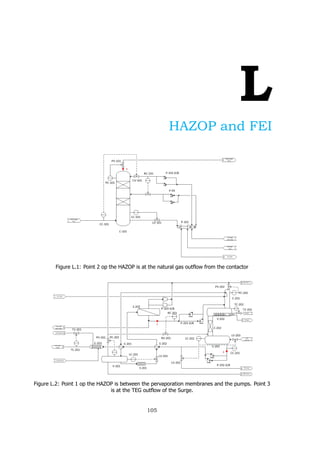

4.5.1. Hazard and Operability study (HAZOP)

For the hybrid system a HAZOP has been performed. For this study three points in the flow scheme

have been chosen as mentioned below.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-55-320.jpg)

![48 4. Hybrid Process

The first one is the TEG flow coming from the pervaporation membranes. The second point is the

natural gas outflow from the contactor. The last point is the TEG outflow from the surge. At these point

the consequences and solutions for problems like too much flow or no flow have been considered. The

results of the HAZOP can be found in appendix L.

Resulting the HAZOP, a few actions need to be taken. In the pipeline of point one, after the

pervaporation membranes should be a concentration and a flow meter which need to be connected to

an alarm. If there are inconsistencies in the values that these controls show then there is something

wrong with either the membranes or the pumps. Also there should be a reverse flow prevention in this

pipe. At point 2, after the contactor there should be a flow meter, for when the flow is too little big or

too little either water is not removed from the gas or gas is leaving via an other route. This controller

should also be connected to an alarm. In order to prevent flow problems at point 3, after the surge, a

level controller has been put on the surge and has been connected to the valves controlling the in and

outflow of TEG from the entire system.

The meters that are only connected to an alarm have not been added to the control scheme in

order to keep the figure clear and readable.

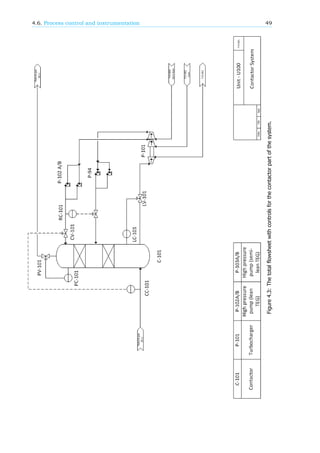

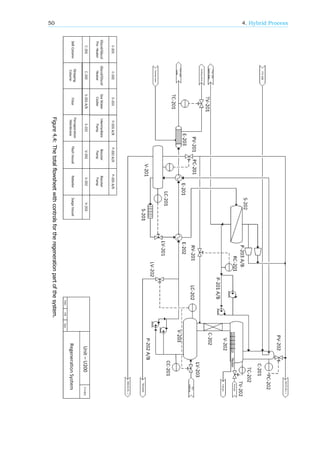

4.6. Process control and instrumentation

The choices have been made following the plan found in the book of Seider, Seader, Lewin and Widagdo

[16]. This book presents 9 steps to end up with a controlled system. The system has been split into

two separate flow schemes, one which contains the contactor, and one that contains the regeneration

steps. In this case both schemes will be dealt with simultaneously. The resulting process control

schemes are shown in figure 4.3 and 4.4.

The entire process starts with the inflow of wet natural gas. The amount of natural gas coming in

is not controlled for this unit but is set at the well head. The amount of TEG needed to dehydrate the

natural gas is dependent on the water content of the natural gas entering the system. The amount of

water present in the natural gas inflow is measured by concentration controller CC-101. This controller

is connected to the valve that controls the inflow of TEG coming from the surge(CV-101). The second

TEG inflow, coming from the pervaporation membranes, is controlled with a ration controller (RC-101)

connected to the previously mentioned stream via RV-101. The rich TEG flow from the contactor is

controlled with a level controller(LC-101) in the contactor via valve LV-101. This is because there should

be a constant level of TEG present in the bottom of the contactor. The natural gas outflow from the top

of the column is controlled with a pressure controller(PC-101) which will be set to a certain pressure

and that way control the outflow via valve PV-101.

The rich TEG first goes to the flash (V-201). Here the gas outflow is controlled with pressure

controller PC-201 with a valve on the outflow (PV-201). The liquid outflow is controlled with a level

controller (LC-201) via valve LV-201. To prevent build up of contaminants in the flash there is an extra

liquid outflow, the drain, which will be manually controlled.

The TEG will now go through the pervaporation membranes to the still column. The gas outflow

from the still column is controlled with pressure controller PC-202 via valve PV-202. The liquid TEG will

go to the reboiler and then the surge without passing another valve. The surge needs a liquid level

between certain values. Liquid controller LC-202 is in charge of this. When the level gets too low, valve

LV-203 will open end lean TEG from storage will come in. If the level gets too high, LV-202 will open

and TEG will flow to the storage tank.

The amount of water that is taken out of the TEG in the still column is primarily determined by the

energy input into the reboiler. There will be a temperature controller (TC-202) which will try to keep

the reboiler at a certain set point by increasing or decreasing the fuel gas going into the reboiler via

valve TV-202. The set point will be determined with the concentration controller CC-201. When the

concentration of water gets too high the temperature in the reboiler needs to be increased and vice

versa.

From the surge the TEG will go through two heat exchangers and then a sea water cooler. The

amount of sea water passing through the cooler is controlled with temperature controller TC-201 which

is placed behind the cooler. The water flow is controlled with valve TV-201.](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-56-320.jpg)

![5

Economic Analysis

In this chapter all investments for both the conventional as the hybrid system are estimated. The

sizes are taken from appendix A. First the total investment costs are estimated using Lang’s method

and secondly the OPEX is estimated. All economic reduction achieved by the new process are in this

chapter.

5.1. CAPEX

All prices are estimated using the Prijzenboekje of the Dutch Association of Cost Engineers [47]. Except

from C-101, P-101 & P-202. These are estimated using the Matche’s website [48]. All prices have been

adjusted to 2014 using CEPCI numbers. If a price was found in US dollars an exchange rate of 1.25

euros per dollar was used to convert it [49]. Finally, a factor of 1.25 is used to transform this prices

from USA to EU displacement.

5.1.1. Conventional

Vessels & columns

Table 5.1: CAPEX for all vessels and columns in the conventional process

Equipment Number Diameter (m) Length (m) Thickness (mm) Price (Euro)

C-101 1 2.04 12.2 190 €1,160,000

C-201 1 0.27 6.5 10 €68,738

C-202 1 0.25 0.5 6 €27,236

S-201 A/B 2 0.0254 - - €6,459

V-201 1 0.55 2.22 6 €23,750

V-202 1 0.53 2.12 6 €23,594

V-203 1 0.72 2.88 6 €25,781

Pumps

Prices of pumps were estimated with the Prijzenboekje [47].

Table 5.2: CAPEX for all pumps inside the conventional process

Equipment Number Capacity (m /h) Head mLc Max. Power (kW) Price (Euro)

P-101 2 2.3 1370 13.4 €19,973

P-202 A/B 2 2.7 20 0.155 €11,932

51](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-59-320.jpg)

![52 5. Economic Analysis

Heaters & Coolers

Prices of heaters were estimated with the Prijzenboekje [47].

Table 5.3: CAPEX for all heaters & coolers inside the conventional process

Equipment Number Area (m ) Price (Euro)

E-201 1 28.45 €35,017

E-202 1 147 €89,489

E-203 1 17.3 €33,720

Total costs

The total investment costs for equipment can be calculated now by adding all these prices. As this

is a fluid and gas plant a Lang factor for process equipment and installation of 5.93 is estimated[50].

This gives a final investment of € 9,047,332. As mentioned by frames a conventional unit has a price

between 5-10 million euros, so this estimate seems to be accurate.

5.1.2. Hybrid

Vessels & Columns

For the calculation of a membrane module price, the following assumptions were take into account:

• The module is considered as a vessel of SS 316. Therefore with 0.26 m diameter, 1.402 m of

length and 6 mm thickness.

• The price of SS 316 is calculated by its weight (97 kg obtained in unit sizing, Chapter 4) following

Matche’s web page [48]. Then a factor of 1.5 of security is added to account the price of the

membrane elements.

The results for the estimated price of one module are presented in the following table 5.4.

Table 5.4: CAPEX for a pervaporation membrane module

Equipment Number Diameter (m) Length (m) Thickness (mm) Price (Euro)

PV module 138 0.26 1.402 6 €20,156

From contact with Pervatech, it was given that a module of 4 elements on 50 cm length with a

weight of 10 kg costs about €5,000. Thus, having a module of around €20,000 is totally feasible. The

other vessels are estimated using the same methods as with the conventional process.

Table 5.5: CAPEX for all vessels and columns in the hybrid process

Equipment Number Dimension (m) Length (m) Thickness (mm) Price (Euro)

C-101 1 D=2.04 12.2 190 €1,160,000

C-201 1 D=0.145 6 13 €73,925

C-202 1 D= 0.25 0.5 6 €27,236

S-201 A/B 2 D=0.0254 - - €6,459

S-202 1 W=7 and H=5 1.402 - €2,781,000

V-201 1 D=0.46 1.85 6 €22,813

V-202 1 D=0.35 1.39 6 €21,563

V-203 1 D=0.48 1.91 6 €22,969](https://image.slidesharecdn.com/10db86e5-b3a1-4553-b5bc-7c80961ebcd4-150915141925-lva1-app6892/85/CDP-FINAL-REPORT-60-320.jpg)

![5.2. OPEX 53

Pumps

Prices of pumps were estimated with the Prijzenboekje [47].

Table 5.6: CAPEX for all pumps inside the hybrid process

Equipment Number Capacity (m /h) Head mLc Max. Power (kW) Price (Euro)

P-101 1 2.5/0.8/0.7 - - €12,813

P-102 A/B 2 0.7 692 2.04 €25,625

P-103 A/B 2 0.7 758 2.17 €25.625

P-201 A/B 2 1.2 7.9 0.027 €13,229

P-202 A/B 2 0.8 15.5 0.045 €13,229

P-203 252.3 - 49 €28.750

Heaters & Coolers

Prices of heaters were estimated with the Prijzenboekje [47].

Equipment Number Area (m ) Price (Euro)

E-201 1 4.424 €33,720

E-202 1 24.35 €35,017

E-203 1 2.64 €27,236

E-204 1 2.44 €27,236

5.1.3. Conclusions regarding CAPEX

When all the prices for hybrid are added to each other and the Lang factor has been incorporated a

price of €25,845,566 arises for total ownership. This is almost three times higher as the conventional

process, which costs € 9,047,332. While all equipment is reduced in size and price the introduction

of membranes is such a big investment that the end price is much higher. This observation is also done

with regard to the weight of the total unit.

5.2. OPEX