Embed presentation

Download to read offline

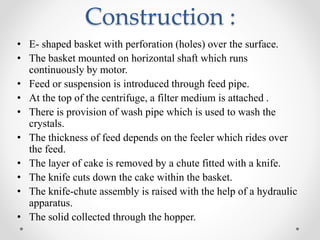

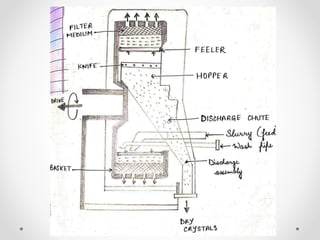

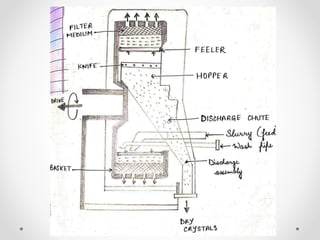

This document summarizes the construction and working of a semi-continuous centrifuge. It has a perforated basket that rotates horizontally on a shaft. Feed is introduced and centrifugal force separates undersized crystals that remain in the basket from the liquid that passes through. When the cake reaches a certain height, the inlet stops and it is washed before a knife-chute assembly cuts and collects the cake. Semi-continuous centrifuges can separate crystals from liquids faster than batch centrifuges but use more power and risk crystal breakage during discharge.