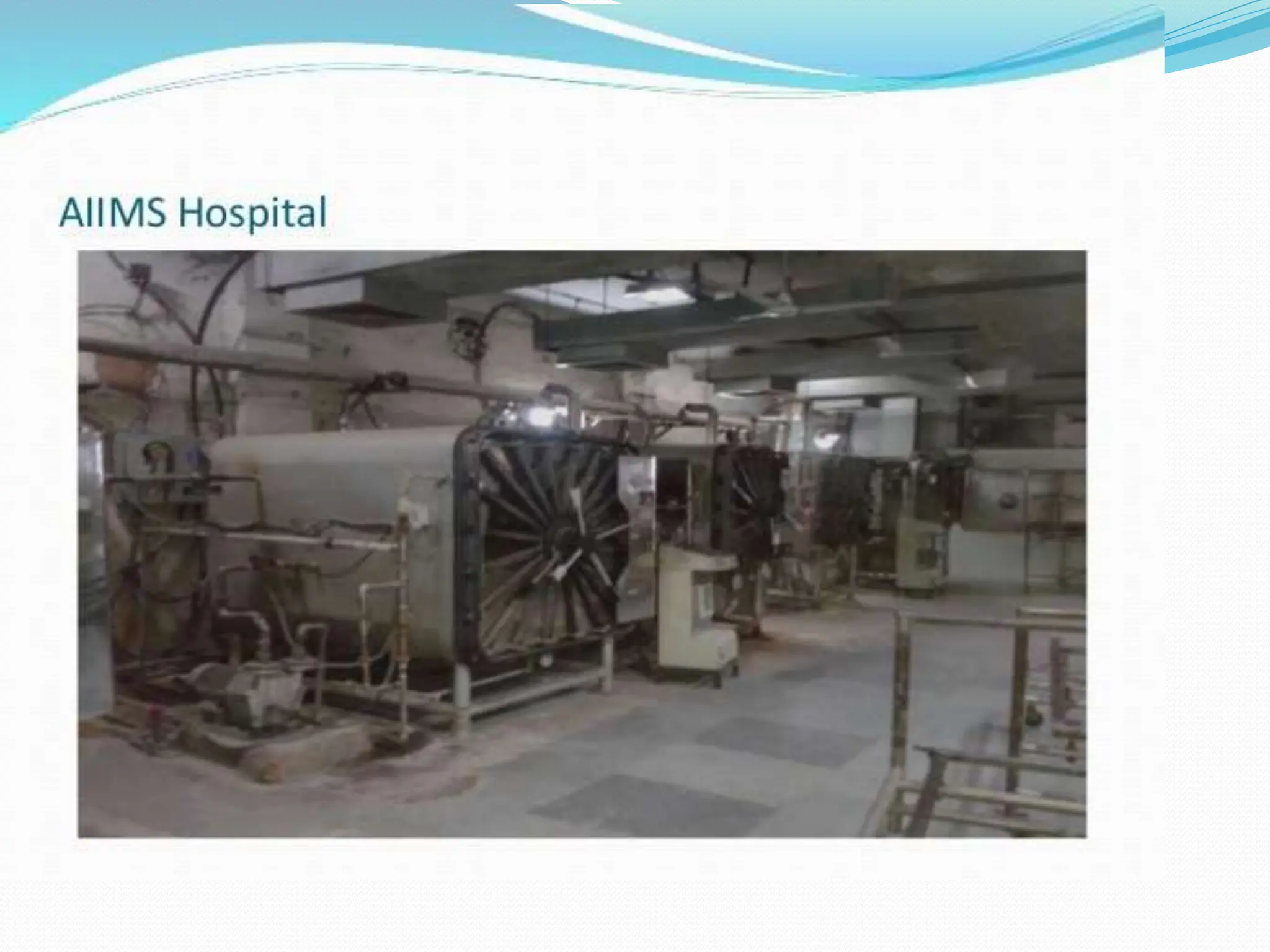

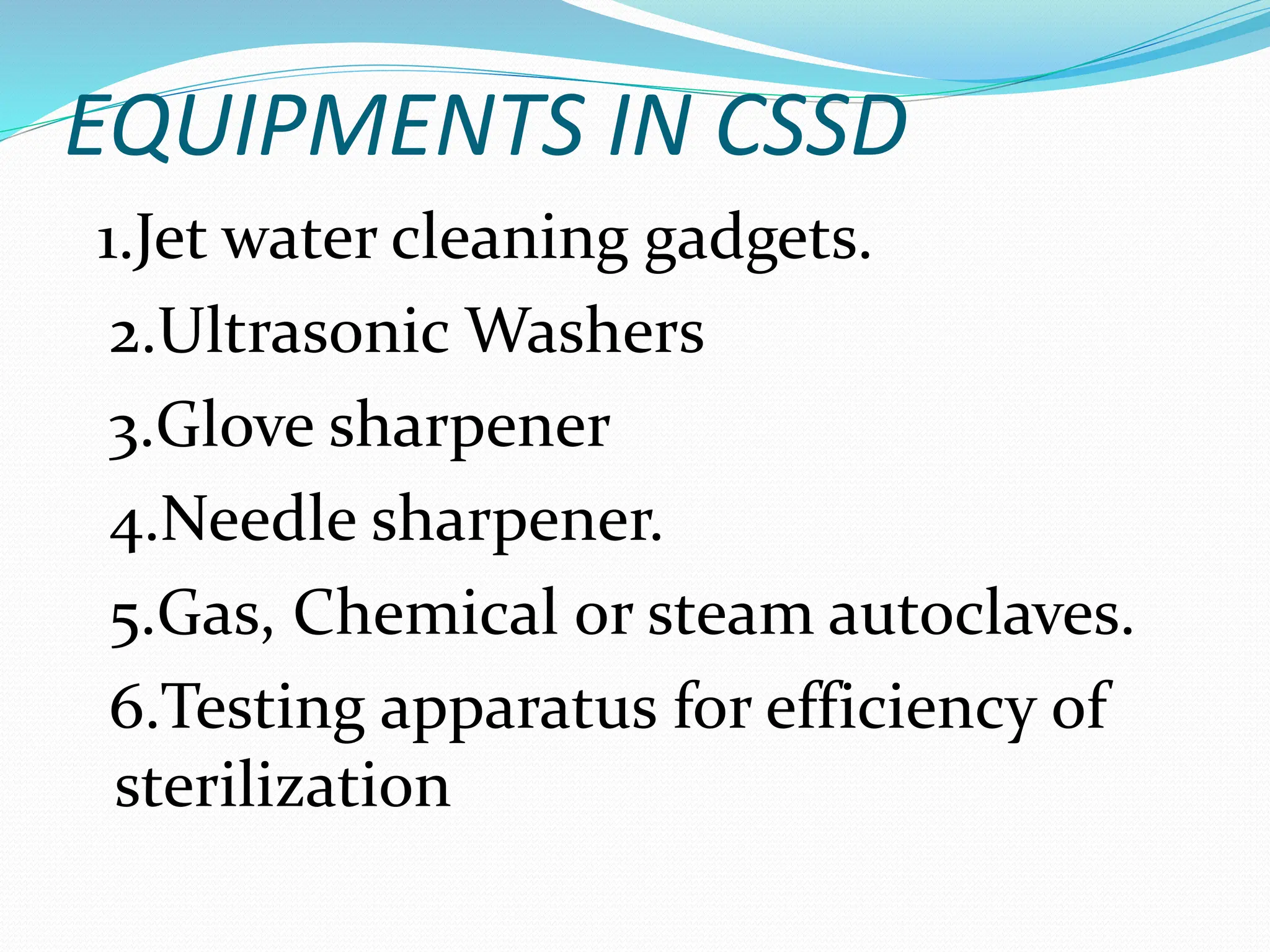

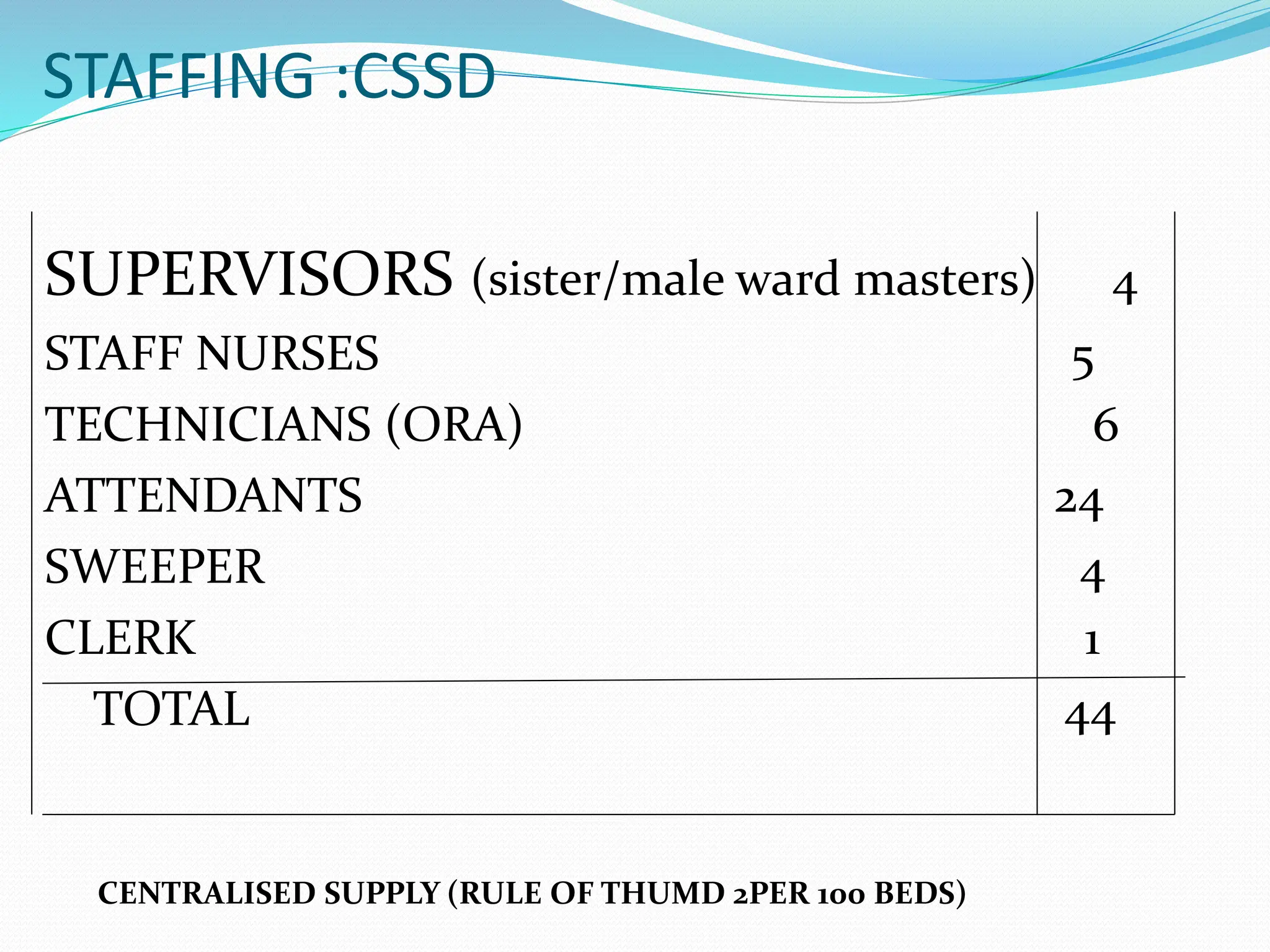

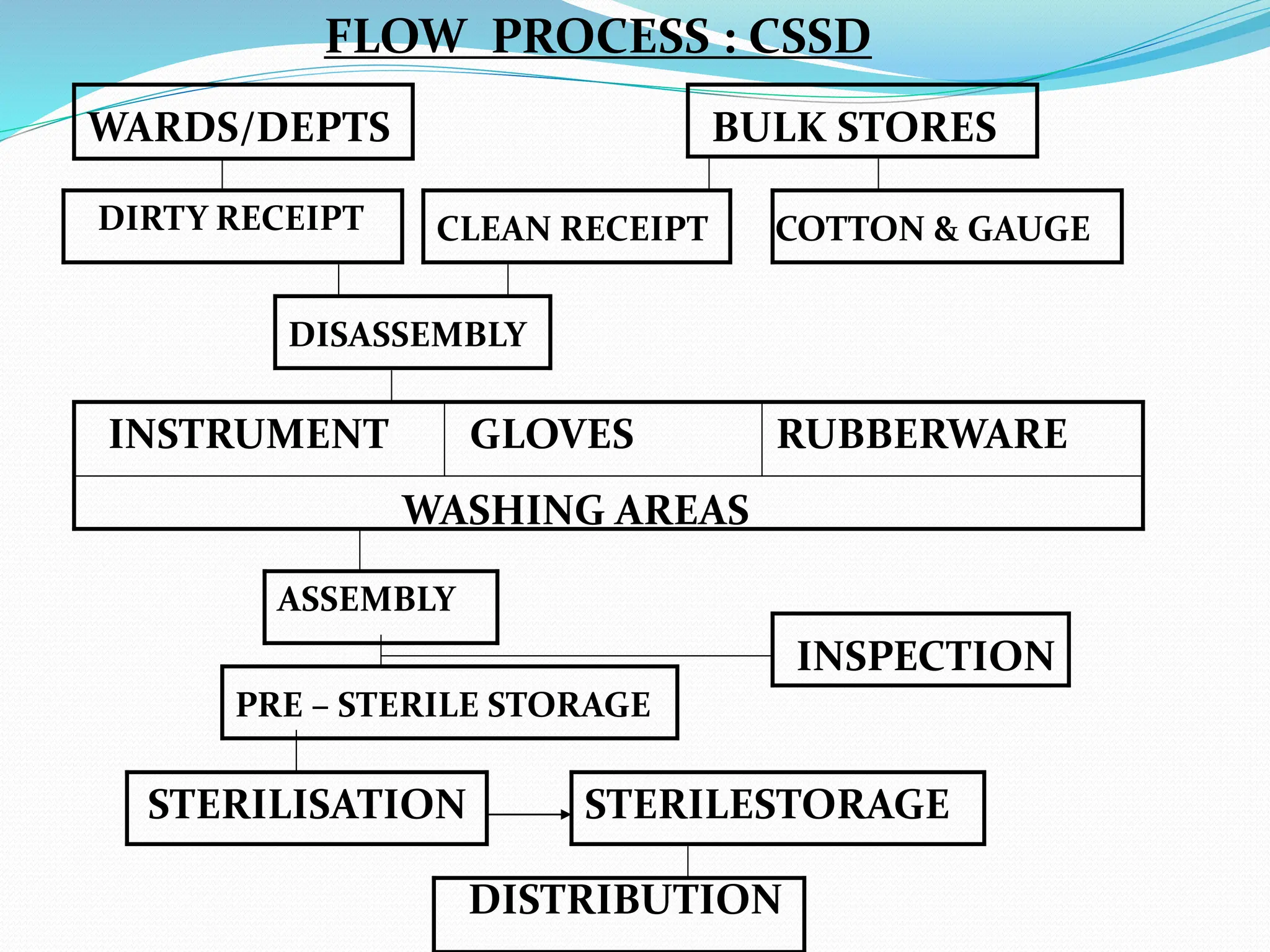

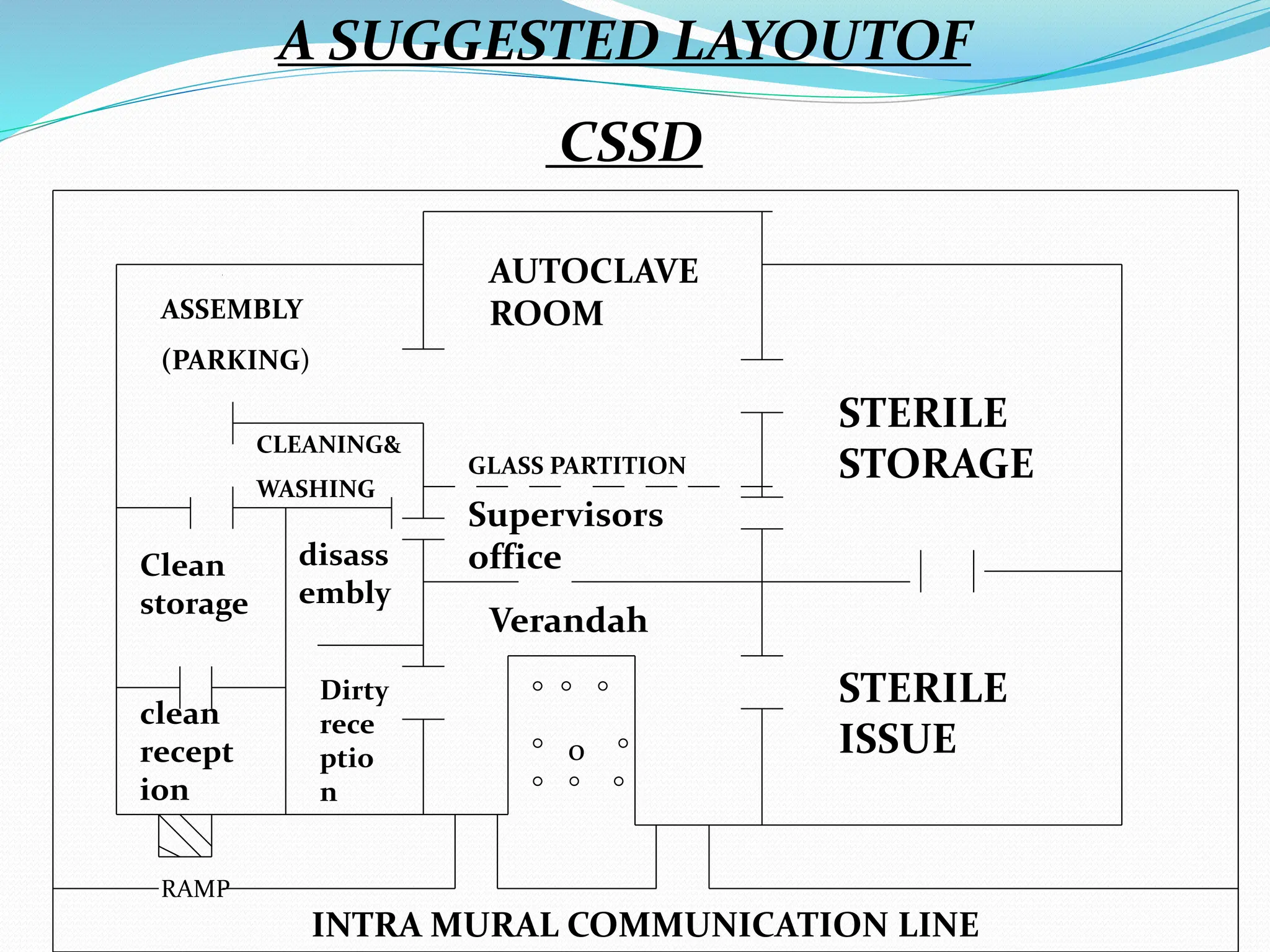

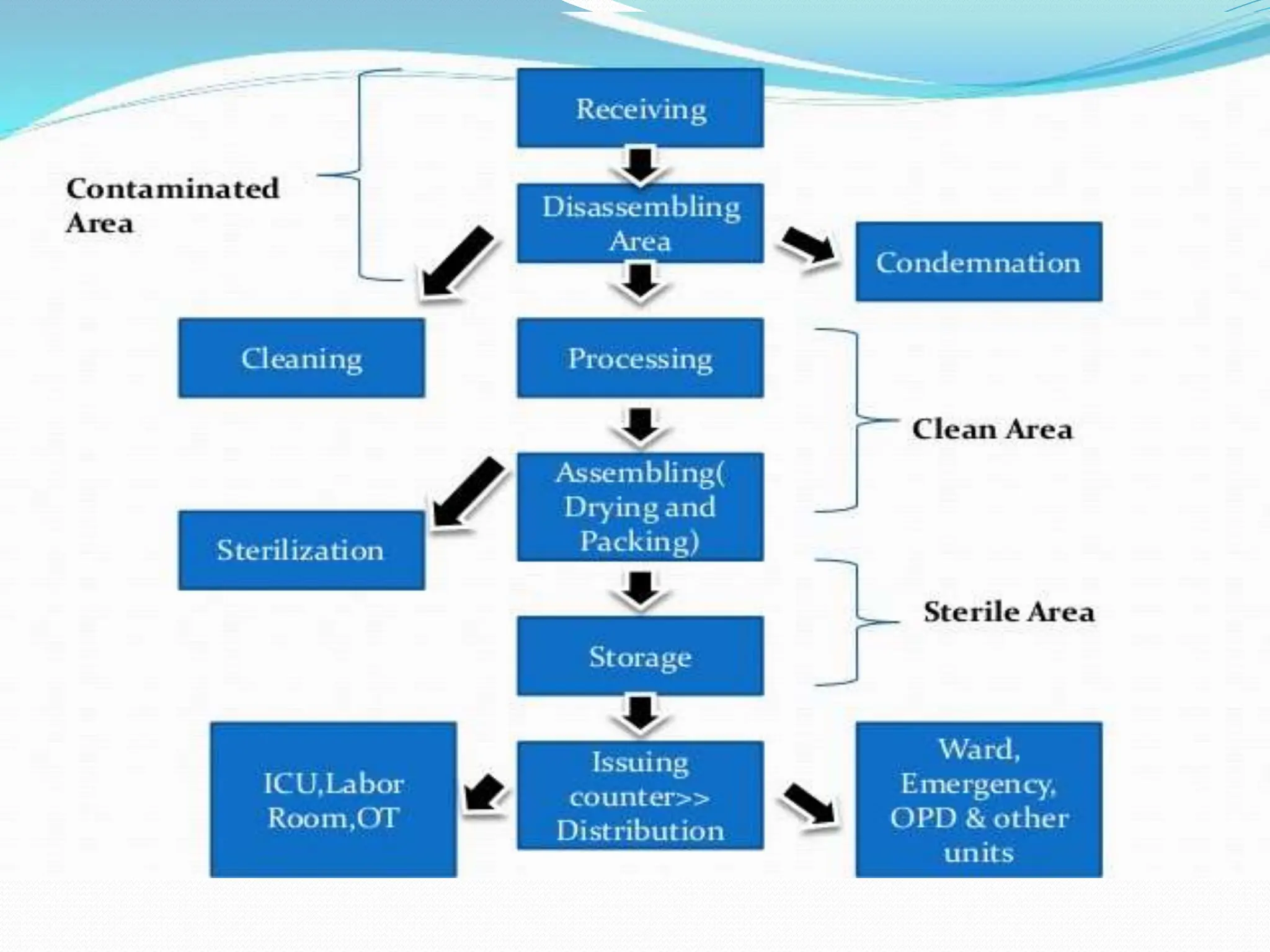

The document outlines the operations of the Central Sterile Supply Department (CSSD) at Mother Teresa PG & RI of Health Sciences, detailing its role in providing sterile supplies and infection control within healthcare facilities. It discusses the processes of disinfection and sterilization, advantages of centralized sterilization, equipment used, and the staffing structure of the department. Additionally, it describes the workflow and layout of the CSSD to ensure efficient sterilization and distribution of sterile materials.