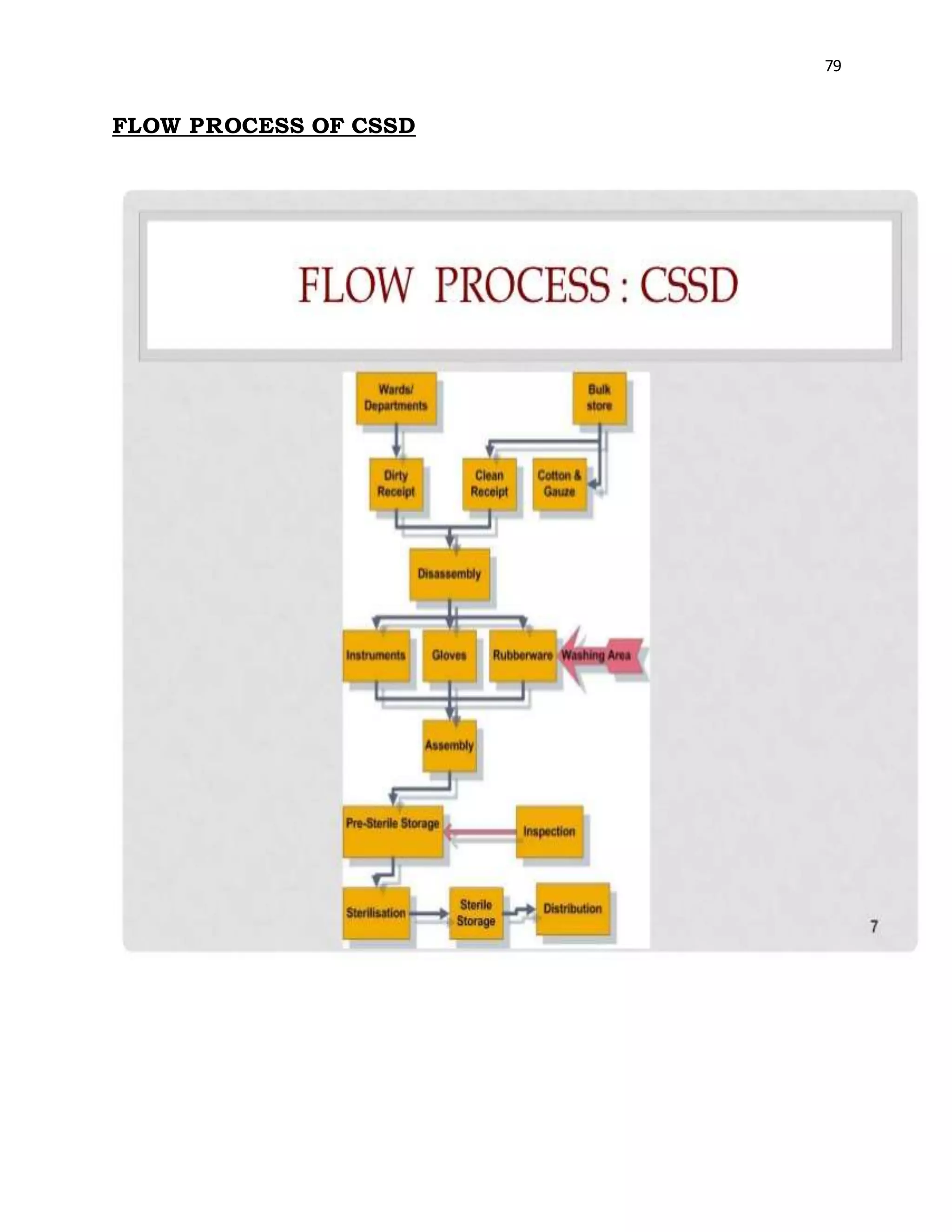

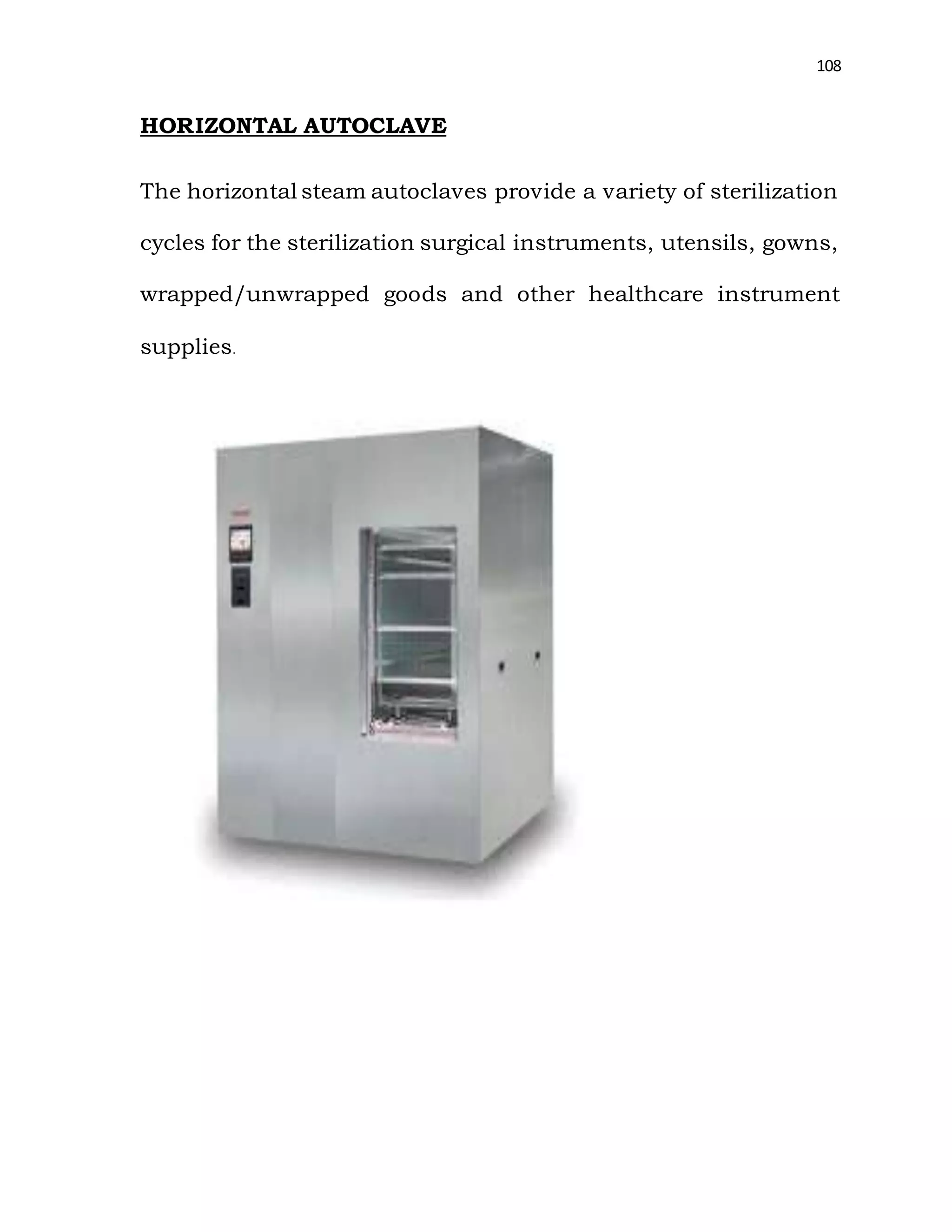

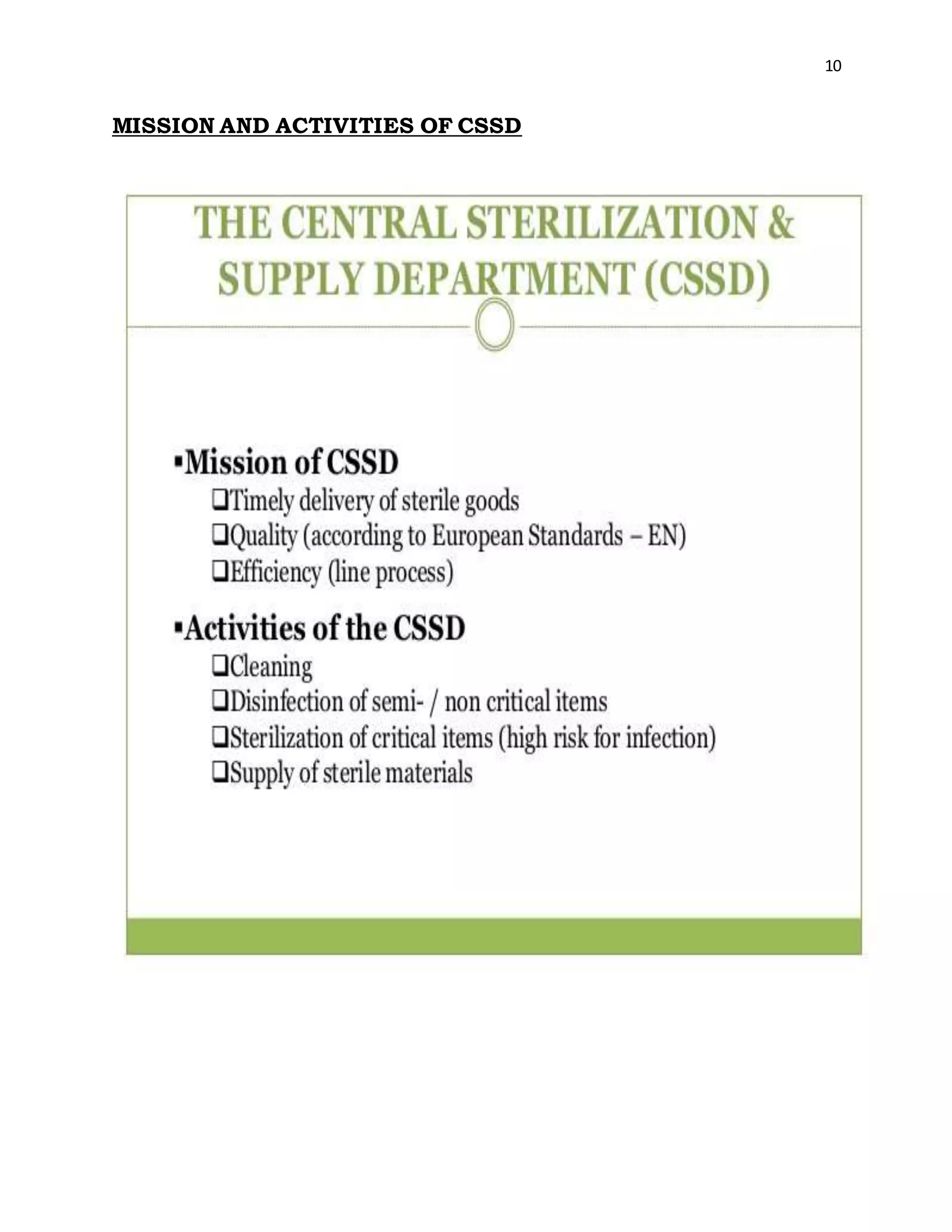

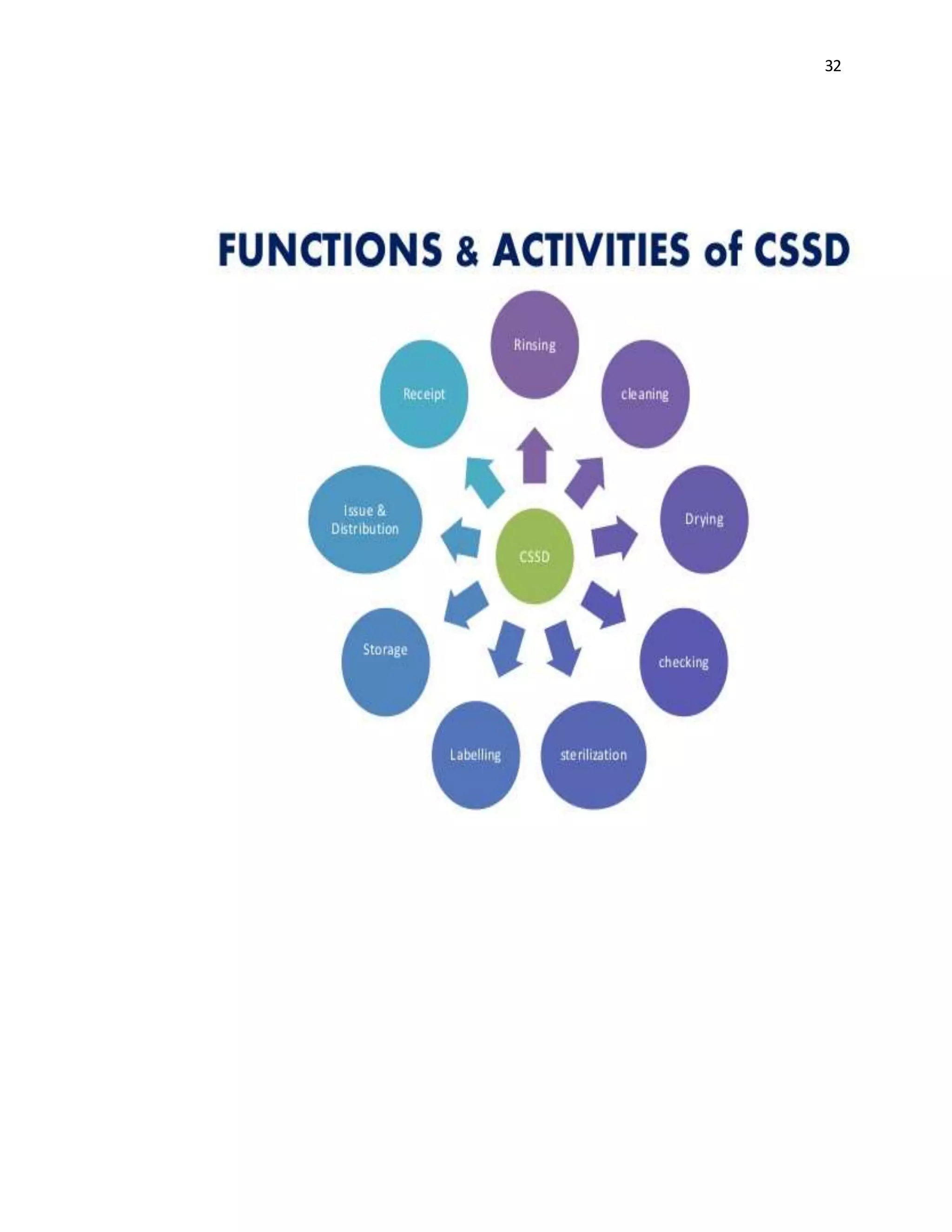

The document is a project report submitted by Megha Milind Sawant for the partial fulfillment of an MBA degree. It discusses conducting a study on the efficiency of the Central Sterile Supply Department (CSSD) in a multispecialty hospital. The CSSD is responsible for sterilizing medical equipment and supplies before use. The objectives of the study are to develop safety checklists for the CSSD and ensure quality sterilization processes to reduce hospital infections and improve patient care. The report provides background information on the CSSD, including its functions, policies, history and objectives.

![46

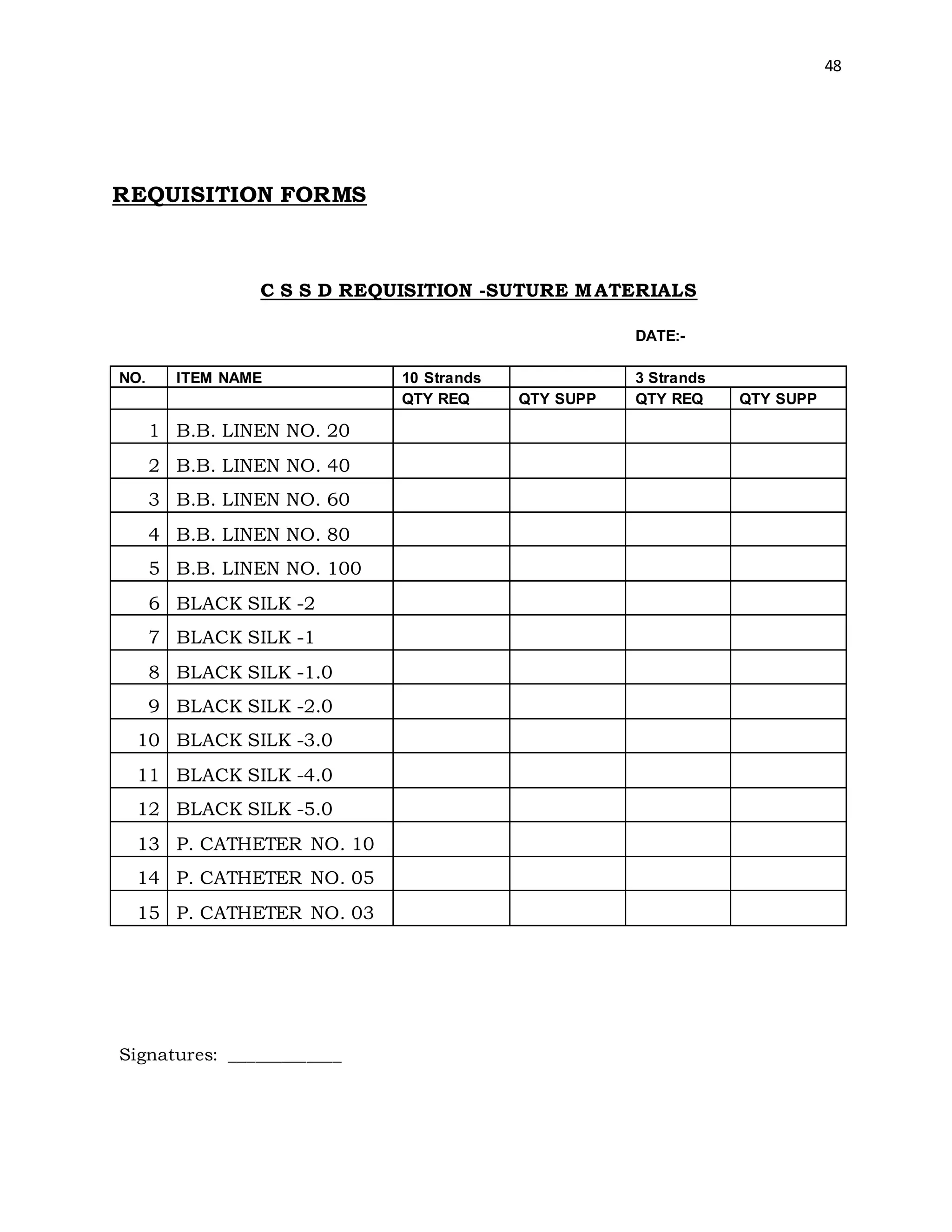

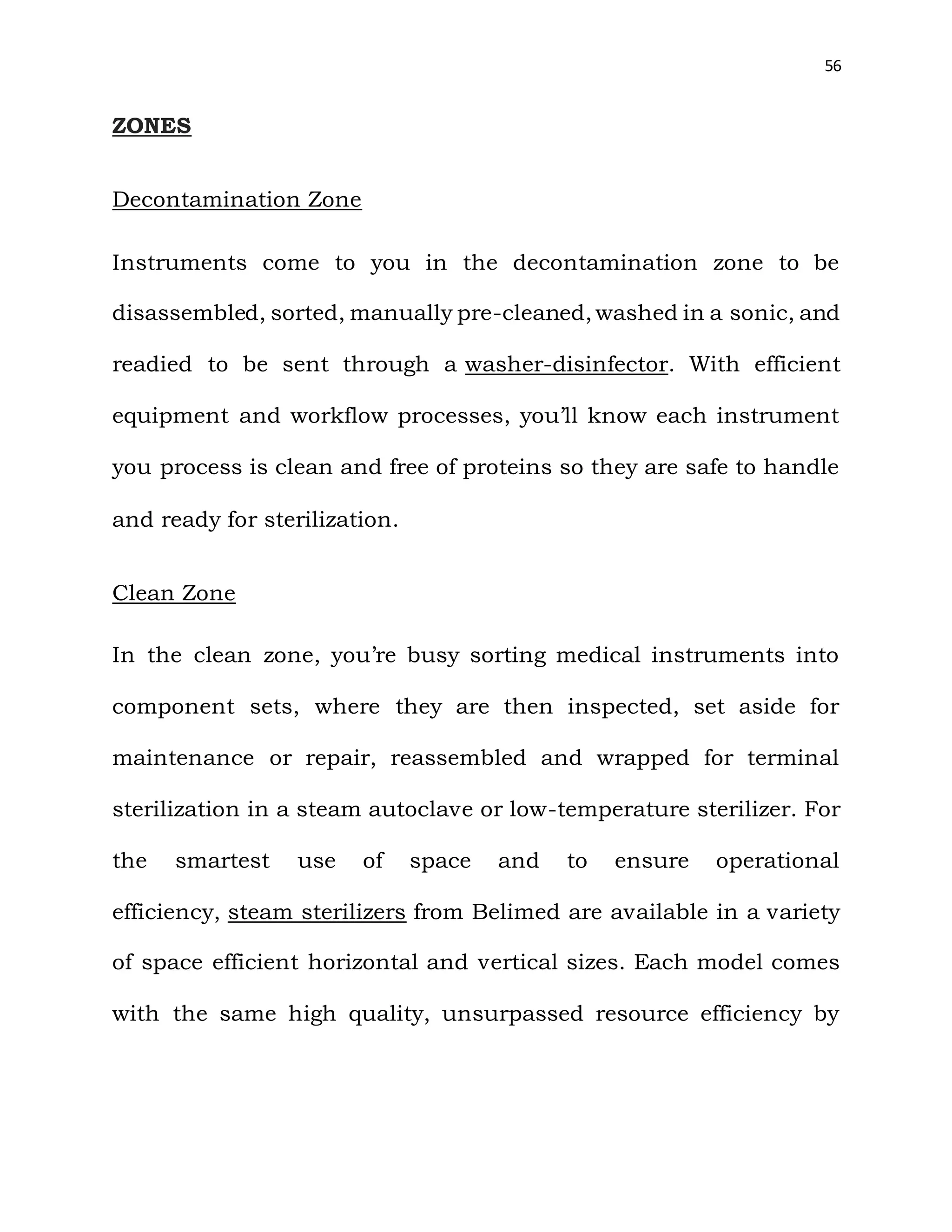

The Grocery System: The departments send their requisition to

CSSD from where deliveries are made in accordance with the

demand. This system is sometimes not practical as some

departments demand the entire amount of stock from the

CSSD having nothing left for the others. The efficiency of the

system depends on the wisdom and experience of the person

making the indent.

The Clean for Dirty Exchange System: According to this

system one clean article is issued for each dirty returned to

the CSSD.

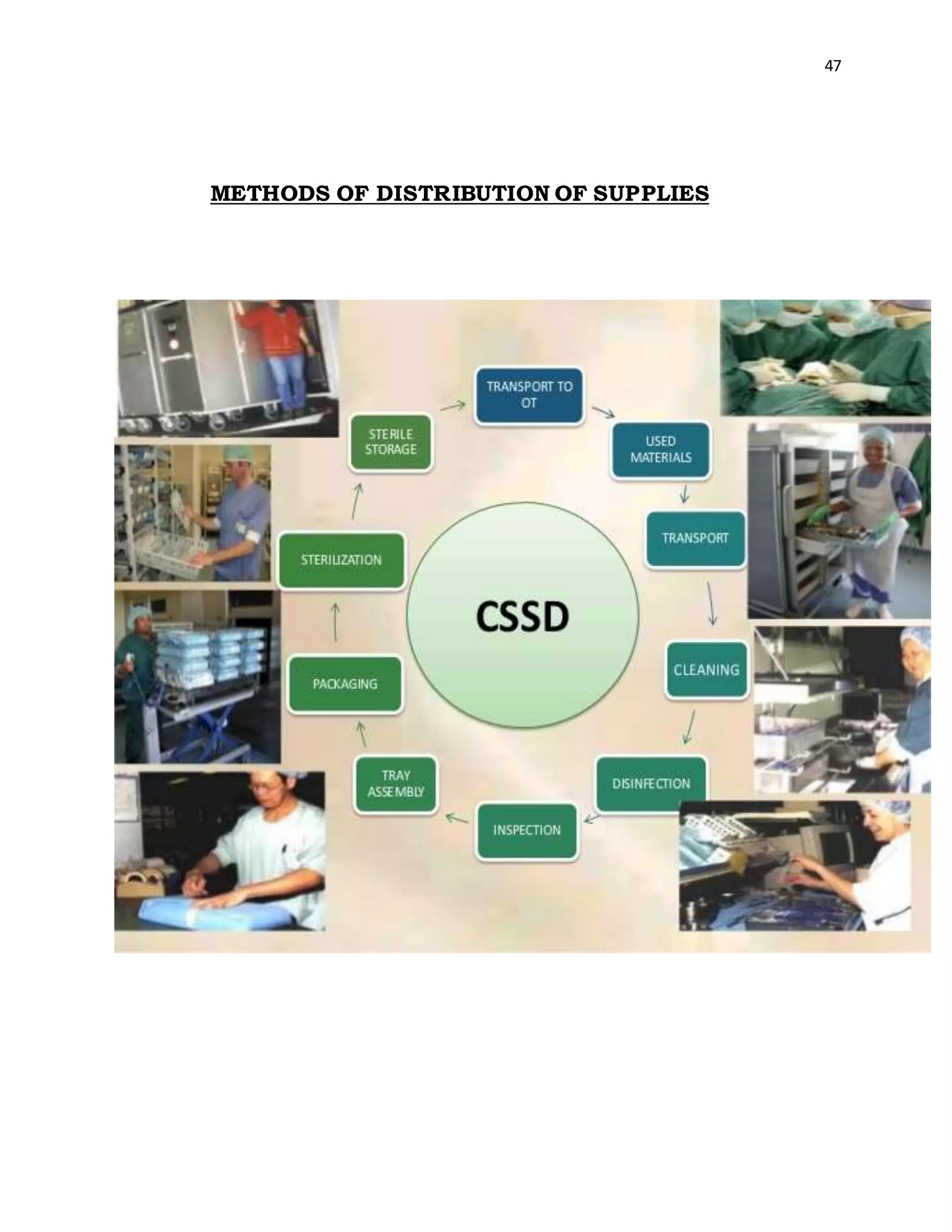

The Sterile Supply Department within a hospital receives

stores, sterilizes and distributes to all departments including

the wards, outpatient department [OPD] and other special

units such as operating theatre [OT]. Major responsibilities of

CSSD include processing and sterilization of syringes, rubber

goods [catheters, tubing], surgical instruments, treatment

trays and sets, dressings etc. it is also responsible for

economic and effective utilization of equipment resources of

the Hospital under controlled supervision](https://image.slidesharecdn.com/astudyonsafetyqualitycareincssd-201108070957/75/A-study-on-safety-quality-care-in-cssd-46-2048.jpg)