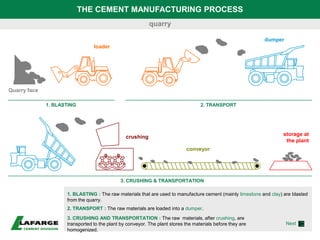

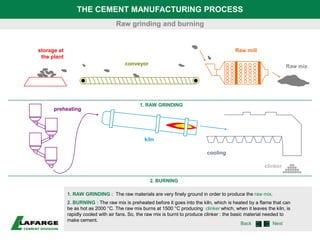

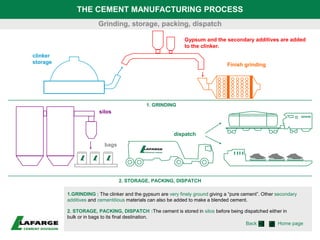

The cement manufacturing process involves quarrying raw materials such as limestone and clay, crushing and transporting them to the cement plant. At the plant, the raw materials are homogenized and finely ground into a raw mix, which is preheated and burnt in a kiln at 1500°C to produce clinker. The clinker is cooled, ground with gypsum and other additives to produce cement powder, which is stored in silos before being packed and dispatched.