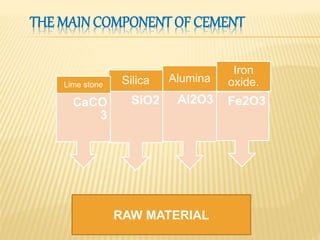

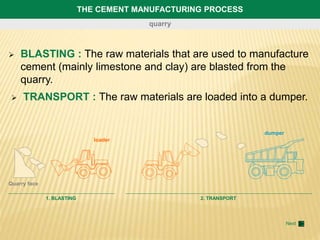

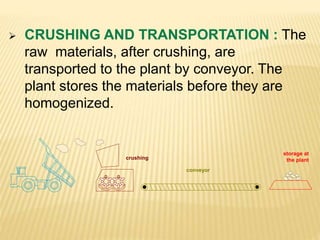

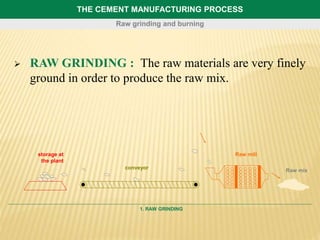

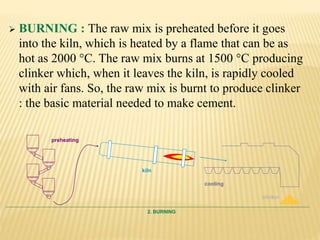

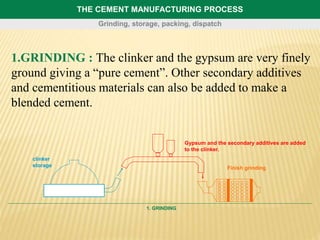

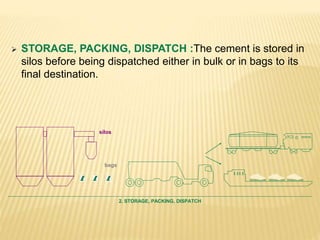

ACC Limited is one of the largest cement producers in India, established in 1963. The document discusses the cement manufacturing process at ACC. It involves blasting raw materials like limestone and clay from quarries, crushing and transporting them to the plant. The raw materials are finely ground to produce the raw mix, which is preheated and burned in a kiln at 1500°C to produce clinker. The clinker is then ground with gypsum and other additives to produce pure cement. Finally, the cement is stored in silos before being packed and dispatched.