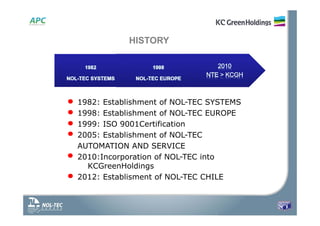

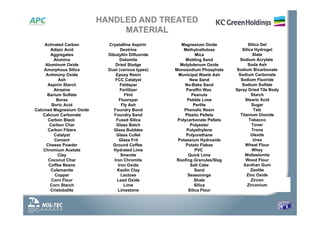

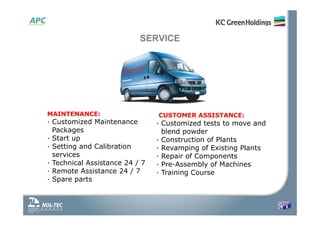

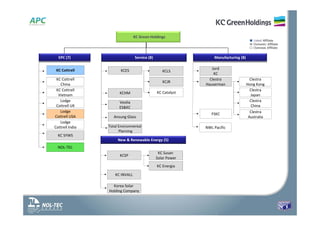

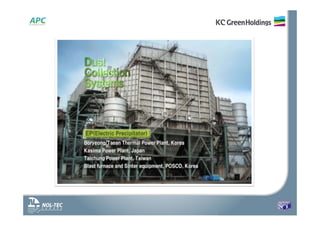

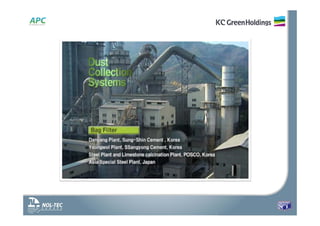

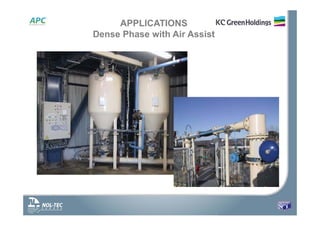

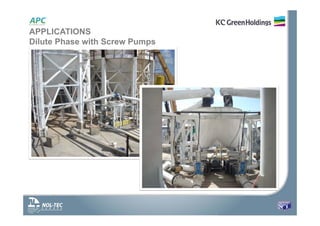

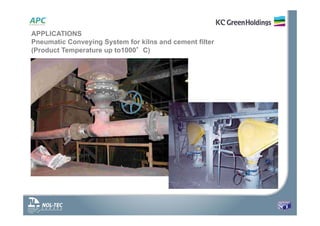

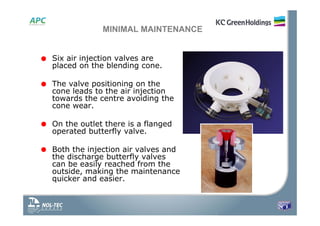

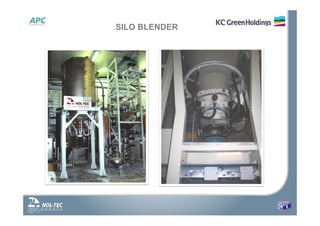

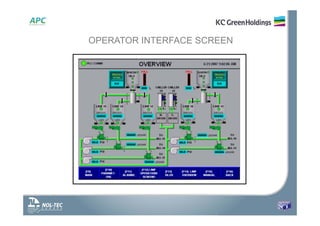

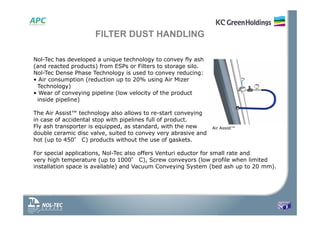

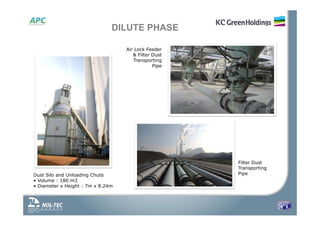

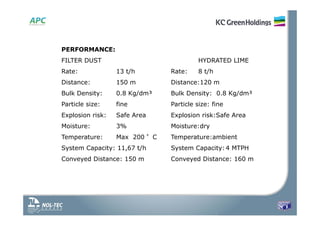

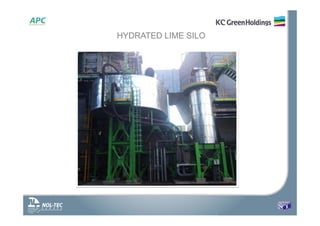

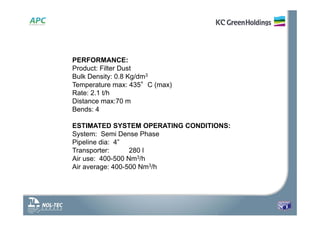

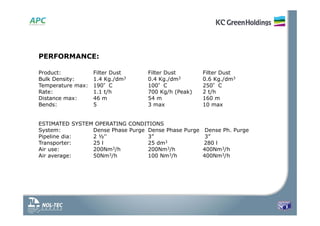

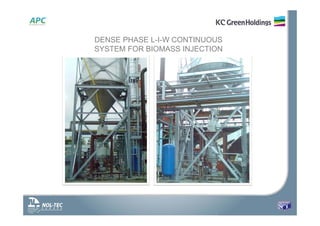

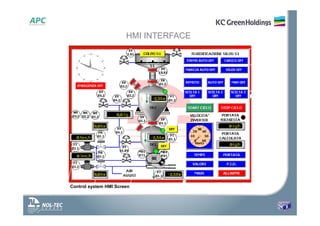

This document provides an overview of NOL-TEC Worldwide, a company that specializes in pneumatic conveying systems and industrial automation. It outlines the company's history, starting in 1982 and expanding globally. It describes NOL-TEC's capabilities such as dust collection systems, dense phase and dilute phase pneumatic conveying, control systems, and various industrial fields it serves. The document also lists over 600 systems realized for customers and materials handled.