This document discusses heat exchangers and provides information on performance fluids from Dow Chemical. It summarizes Dow's portfolio of advanced performance fluids for applications such as heat transfer, lubrication, fluid power, freeze protection, corrosion protection, and deicing. The fluids help improve processing efficiency, prevent corrosion and freeze damage, protect systems, reduce wear, and offer economic and fire resistance benefits. The document encourages choosing Dow's performance fluids for applications requiring critical functional and protection needs.

![Pipe Sizing

Department Editor: Kate Torzewski

Friction Factor Hydraulically smooth pipes. Equations (1)

NOMENCLATURE

and (3) allow us to find an expression for the

Fluid flowing through pipes experiences discharge of a smooth pipe. D Diameter of pipe, m

resistance due to viscosity, turbulence and

DR Diameter of very rough pipe, m

roughness of the pipe surface. The Darcy-

DS Diameter of very smooth pipe, m

Weisbach Equation (1) is commonly used for

(10) D1 Diameter of standard commercially

the analysis of steady-state, Newtonian-fluid available pipe, m

flow inside pipes. It summarizes the relations f Darcy friction factor, dimensionless

between frictional head loss, fluid properties,

g Gravitational acceleration, m/s2

pipe geometry and discharge. (11) Gu Dynamic roughness, dimensionless

Commercial pipes. Equations (1) and (6) allow hf Frictional head loss, m

us to find an expression for the discharge of a L Length of pipe, m

(1)

commercial pipe. Q Volumetric flowrate, m3/s

For laminar flow (Re 2,100), the friction fac- P Pressure drop, N/m2

tor is a function of Reynolds number only. Re Reynolds number, dimensionless,

Re = 4Q/D

(2)

X Dimensionless parameter (Eq. [11])

In turbulent flow (Re 4,000), f depends upon Pipe roughness, m

Reynolds number and pipe roughness. Dimensionless parameter (Eq. [16])

Hydraulically smooth pipes. In this case, the Viscosity, N-s/m2

friction factor is solely a function of Re. For the (12)

Density, kg/m3

determination of friction factor, Von Kármán Diameter multiplier, dimensionless

and Prandtl [2] developed Equation (3). Pipe Diameter

Rearranging Equation (1) to yield an expres-

1.8

(3) sion for pipe diameter gives Equation (13).

1.7

This correlation must be solved by iterative

procedures, but simpler correlations given by 1.6

Diameter multiplier, ψ

Colebrook [3] and Blasius [4] are written as (13) 1.5

Equations (4) and (5), respectively. Smooth pipes. Substituting Equation (5) for f 1.4

Re yields a correlation for pipe diameter.

1.3

(4) 1.2

(14) 1.1

(5)

Commercial pipes. Determining the diameter 1.0

Commercial pipe. In this case, f is governed

of a rough pipe requires the use of Gu, the 0.9

by both Re and relative roughness, expressed 1 10 100 1,000 1x104 1x105 1x106

dynamic roughness.

as ε/D. The Colebrook-White’s Equation (6) is Gu

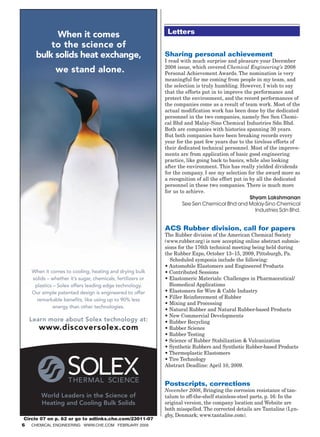

used to calculate f [3]. (15) Figure 1 is a plot with Gu as abscissa and Ψ as

Manipulating Equation (7) to reflect Gu and ordinate. It has the expected limit at Gu = 0, at

substituting into the expression for pipe di- Ψ = 1. First, estimate a pipe diameter assuming

(6)

ameter gives Equation (17), commercial pipe smooth pipe. Using this diameter, calculate Gu from

As this equation requires trial-and-error solu- diameter. Several design parameters can be Equation (15). Then, from Figure 1, get the value

tion, Altshul [5] has developed Equation (7), a condensed into a constant, named λ.

of Ψ and multiply it by the diameter to get actual

computationally simpler choice. diameter needed for the commercial pipe.

(7) (16) Graphical Sizing Method

To avoid lengthy calculations, a graphical

Pressure Drop method can be used to approximate pipe

(17) diameter. Dividing Equation (17) by Equation

To determine pressure drop, discharge and

The range of Gu is: 0 Gu 106, based on (18), we get the diameter multiplier, Ψ.

diameter must be known.

Hydraulically smooth pipes. Using Equa- the known ranges of Re and ε/D for all pipe

tion (1) and the friction factor correlation for and flow conditions. Substituting these two ex- (20)

smooth pipe, Equation (8) is found. treme values of Gu into Equation (15) gives the A graphical method using Ψ can help to quickly

following extreme cases, which a pipe diameter estimate the degree of roughness the chosen

must fall between. pipe can withstand.

Case 1: Extremely smooth pipe. Gu = 0.

(8) References

Commercial pipes. Using Equation (1) and 1. ulyani, B. B., Approximating Equations for Pipe Siz-

G

the friction factor correlation for smooth pipe, ing, Chem. Eng., February 2001, pp. 105–108.

(18)

Equation (9) is found. 2. on Kármán, T. J., Turbulence and skin friction, J.

V

Case 2: Extremely rough pipe. Gu = 106 Aerospace Sci., 7, 1–20, 1934.

3. olebrook, C. F., and White, C. M., J. of Institution

C

of Civil Engineers (London), 10, 1, pp. 99–118,

(9) 1937–1938.

(19) 4. lausius, H., Das Anlichkeitsgesetz bei Reibungs-

B

Discharge Here, we see that even for very rough pipe (ε/D

vorgängen in Flüssigkeiten, Forschungsarbeit Arb.

Ing.-Wes., No. 131, Belin, 1913.

To determine discharge, pressure drop and = 0.01, Re = 108), the diameter estimate will be 5. ltshul A. D., and Kiselev, P. G., “Gidravlika i Aerodina-

A

diameter must be known. only about five thirds of that for smooth pipe. mika,” 2nd ed., pp. 166–`96, Strojizdat Moscow, 1975.

10_CHE_021509_FACTS.indd 31 1/26/09 9:10:13 AM](https://image.slidesharecdn.com/chemicalengineering200902-130204110833-phpapp02/85/Nano-Know-How-33-320.jpg)

![Cover Story

given as half the wavelength of light position, bonding and atomic spacing. phonograph arm with a needle read-

used; the limit is sometimes given as TEM is usually more successful when ing a record surface.

200 nm which is about half the small- thinner samples are used. Because of the great sensitivity of

est wavelength for visible light. This measurement possible, very detailed

makes it of limited use in nanotech- Scanning tunneling microscopy maps of surfaces can be obtained. The

nology, which has a usual upper limit Another technique that is very popu- technique can be used to sense surface

of interest of 100 nm. There are some lar in nanocharaterization is Scanning topography, for height or other proper-

newer near-field techniques, however, Tunneling Microscopy (STM), which ties, to very small resolutions. Spacial

that are said to get this limit down to was mentioned earlier in the discus- resolutions well below 1 nm have been

a tenth of the wavelength used. sion about the Schrodinger equation. In reported — there is at least one report

STM, a sharp metallic tip is brought in of a figure as low as 0.01 nm, which, if

Electron microscopy close proximity to a sample with either accurate, would be truly remarkable,

A further improvement on microscopy the tip or the sample or both capable considering this is one-tenth the diam-

can be achieved by recognizing that of being precisely moved to allow for eter of a hydrogen atom. Interestingly,

electrons have a wave-like character. a tightly controlled gap and scanning the tips may be chemically modified

Therefore, they can be used in micros- of the sample surface. The main limi- and adapted accordingly for very de-

copy like light. Electron wavelength is tations of this technique are that the tailed chemical or biological sensing.

inversely proportional to the square sample must be reasonably electrically One advantage of AFM over STM is

root of the electron’s acceleration volt- conducting, and only a small surface its ability to analyze non-electrically

age. Resolutions of 1 nm down to 0.1 area can usually be scanned. conducting samples.

nm have been reported for electron From the solution of the Schro-

microscopes. These microscopes have dinger equation for this situation, it Other techniques

been used in some form for many can be shown that the probability of Other techniques useful in nanochar-

years; however, they have been re- tunneling, and hence tunneling cur- acterization involve various surface

cently improved in many respects. One rent, is proportional to exp[–1.025 d(U bombardments with either charged

important difference between electron – E)1/2], where U and E are expressed particle beams or electromagnetic

microscopes and ordinary light micro- in electron volts (eV) and d is the dis- waves, such as focused ion beams,

scopes is in the lenses used; electron tance between the tip and sample in focused electron beams or X-rays.

microscopes do not use glass lenses, angstroms (1 angstrom equals 0.1 Ions or electrons from the beam or

but rather some form of electromag- nm). (U – E) can be approximated by sample coming off, as well as photons,

netic or similar lenses. the average work function of the tip X-rays, fluorescence or the like may

There are two major kinds of elec- and sample; the work function is the be detected and used to characterize

tron microscopy: Scanning Electron amount of energy required to remove properties of the sample with various

Microscopy (SEM) and Transmission an electron from a surface. From this resolutions, depending on the exact

Electron Microscopy (TEM). The main proportionality, we may determine technique. These properties may sim-

difference is in what the electrons do many facts about a particular surface. ply be surface height topography, but

or which electrons are used in detec- For example, taking 5 eV as a normal at times might also be something else,

tion. In SEM, the electron beam scans average work function, the tunneling such as chemical composition — sur-

across the field of interest, and the current will change by an order of mag- face or otherwise. These techniques

electrons that are knocked off the nitude for each 1 angstrom change in d. are often termed spectroscopic, and

surface atoms — or sometimes from a This sort of data indicates changes in may be more familiar to readers, at

little deeper as well — and those from surface height topography and yields least in general principles, than some

the beam that bounce off the surface surface maps on a very small, even of the microscopic techniques dis-

are detected and used in characteriza- atomic scale of resolution. Resolutions cussed previously.

tion of surface or deeper features. of 0.1 nm have been reported for STM. Specific examples include Scanning

In TEM, the electron beam is aimed This technique has been adapted to Ion Mass Spectroscopy (SIMS), where

at the field of interest, and the trans- chemical analysis, and even manipu- an ion beam hits a sample and ions

mitted electrons — those that pass lation, down to the single-molecule or knocked off the sample are detected;

through the sample and perhaps even atomic level. Particle Induced X-ray Emission (PIXE),

some knocked off sample atoms and where a high energy ion beam (such

through the sample — are detected Atomic force microscopy as of helium ions) hits the sample and

for characterization. Of the trans- A newer and very popular technique emitted X-rays are detected; and X-ray

mitted electrons, three types may be is Atomic Force Microscopy (AFM). Photoelectron Spectroscopy (XPS),

detected for different purposes: the This technique involves bringing a where samples are hit with X-rays and

unscattered carry information about cantilever with a sharp tip over the photoelectrons coming off the sample

the sample thickness, the elastically surface of interest; the tip-surface in- are detected. These three specific tech-

scattered carry crystallographic type teraction, a force, results in deflection niques are all very good for providing

information and the inelastically or oscillation of the cantilever, which detailed chemical analyses, especially

scattered carry information on com- is measured. An analogy for this is a over small spacial ranges.

36 Chemical Engineering www.che.com February 2009

14_CHE_021509_KT.indd 36 1/23/09 3:04:25 PM](https://image.slidesharecdn.com/chemicalengineering200902-130204110833-phpapp02/85/Nano-Know-How-46-320.jpg)

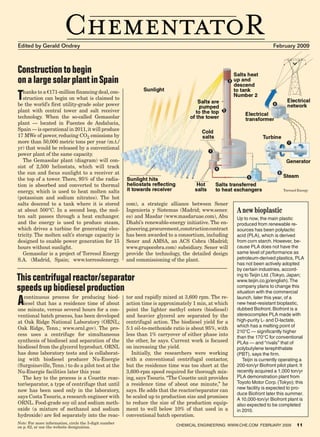

![Feature Report Part 1

Plate Heat Exchangers:

Avoiding Common Misconceptions

Jeff Kerner

Alberts Associates, Inc.

A solid understanding of the critical areas

presented here will insure good performance

T

he use of gasketed plate-and-

frame heat exchangers has

gained tremendous acceptance in primarily for dairy applications. In cleaning. Still, for clean fluids in non-

the chemical process industries these services, low temperatures of cycling services requiring compact-

(CPI) over the past 20 years due to 95°C and pressures of 3 5 barg were

– ness and efficiency and where design

their high heat-transfer coefficients, not of concern. To make the transition temperatures and pressures exceed

compactness and low cost. However, it to industrial applications, gasketed- the capability of gasketed types, these

is important for the engineer who is plate heat-exchanger manufacturers gasket-free plate heat exchangers are

selecting this type of heat exchanger in the 1960s developed pressing pat- a valuable alternative. (See Part 2,

to be aware of critical areas in design terns leading to “stiffer” plates and pp. 44–47 for more on these types of

or selection so that possible operat- more secure gasket sealing techniques heat exchangers.)

ing or maintenance problems can be that allowed design temperatures and An easy to remember and good rule

avoided once the heat exchangers are pressures of up to 115°C and 10 barg. of thumb that the author likes to use

in use. This article addresses these Since then, however, manufactur- when considering the limits for stan-

critical areas, which should be con- ers have made significant strides in dard gasketed “plate and frame” heat

sidered at the very beginning of the expanding the temperature and pres- exchangers is “350°F and 300 psig,”

equipment-design task. sure envelopes within which these for the design temperature and design

Today, while there are a variety of heat exchangers can safely work. pressure, respectively.

heat exchangers using thin, corru- Standard, gasketed plate-and-frame

gated plate technology, the gasketed heat exchangers now routinely are Fouling considerations

type of plate heat exchanger (Figures available with elastomeric seals that It has been demonstrated over the

1 and 2) is the one most familiar to the can be used with confidence up to years by many sources (Ref. [1, 2] are

engineer and is therefore the focus of 180°C. Maximum design pressures typical) that plate heat exchangers

this article. The author will point out for gasketed plate heat exchangers exhibit — and can be designed for —

more recent design variations of corru- can reach in excess of 20 barg, which, much lower fouling factors than con-

gated plate technology that uses plate while not viewed as high for some in- ventional shell-and-tube designs. This

packs that are sealed without gaskets dustries, probably covers 90% of most is due to the turbulence and high wall-

using brazed plates, laser-welded CPI applications. shear stress that the fluids in plate

plates or newer, fusion-based sealing As mentioned earlier, the devel- heat exchangers exhibit, due to highly

technology, which may allow the engi- opment of brazed, laser-welded and turbulent flow between corrugated,

neer to expand beyond the limitations fused plate technology has allowed parallel plates. The author prefers,

of the gasketed plate type. In any case, the fabrication of gasket-free plate though, to clarify this greater fouling

it is important to note that high turbu- heat exchangers (Figure 3). This has resistance as resistance to “micro-foul-

lence and high wall-shear stress due expanded the operating boundaries ing” (that is, fouling due to sedimenta-

to flow in closely spaced corrugated of plate heat exchangers to tempera- tion of suspended fine particles, scal-

plate channels is the key to the high tures of up to 550°C and pressures up ing, crystallization or some biofilms).

heat-transfer coefficients and com- to 54 barg. However, the overall appli- In this case, it is very important that

pactness for this general class of heat cation of welded-plate heat-exchanger the engineer bring to the attention of

exchangers, whether they be gasketed technology is limited by fatigue char- the manufacturer, who is carrying out

or gasket-free. acteristics of the plate if temperature the design of the plate heat exchanger,

or pressure cycling is a factor in the the presence of these phenomena and

Limitations of P and T process for which they are consid- their fouling potential so that the

Most importantly, the engineer select- ered. In addition, these gasket-free manufacturer can design the plate

ing gasketed plate exchangers must types should not be used for fluids heat exchanger for high wall-shear

be aware of their temperature (T) that contain solids or tend to foul, stress. Wall shear stress is a measure

and pressure (P) limitations. When since for most of them, the sealing of the stress along the face of the cor-

plate heat exchangers were first de- methods used do not allow opening of rugated plate expressed as a pressure

veloped in the 1930s, they were used the heat exchanger for inspection or (force/area). In a plate heat exchanger,

40 Chemical Engineering www.che.com February 2009

15_CHE_021509_GSO1.indd 40 1/22/09 11:46:20 AM](https://image.slidesharecdn.com/chemicalengineering200902-130204110833-phpapp02/85/Nano-Know-How-50-320.jpg)

![Alfa Laval Alfa Laval

Figure 2. Corrugated plates, such

as the one shown here, are used in

the most familiar type of gasketed

plate heat exchangers

fouling, these materials are not avail-

Figure 1. able in corrugated plate technology.

Shown here is a cut

away of a gasketed type of

plate heat exchanger. The corrugated Shell-and-tube fouling factors

plates are shown in more detail in Figure 2 Plate-heat-exchanger fouling factors

can be as low as one tenth that of shell-

the wall shear stress, t, is calculated ate contact points where fibers can get and-tube fouling factors for the same

using Equation (1): trapped, building up over relatively fluids [2]. There is a danger in using a

short periods of time and plugging shell-and-tube fouling factor in plate-

t = (DP s)/2L (1)

flow paths, requiring that the heat heat-exchanger designs, since, like

where exchanger be opened (perhaps too fre- other parallel flow path heat trans-

t = wall shear stress, Pa or N/m2 (SI), quently) for cleaning. In these cases, fer devices, this is usually achieved

or psi (U.S.) the engineer should consider the wide- in a plate heat exchanger by adding

DP = pressure drop through plate heat gap plate heat exchanger, which does plates in parallel, thus lowering the

exchanger, Pa (psi 6,894 = Pa) a good job of passing fibers and large flow rate per channel, which results in

s = plate pressing depth, mm particles and has become a workhorse lowering the pressure drop in the heat

L = effective plate length, mm (mea- in ethanol plants and other bio-based exchanger. This lower pressure drop,

sured as centerline-centerline dis- chemical manufacturing processes in turn, lowers the wall shear stress

tance between top and bottom ports where fibers are a natural occurrence and fluid velocity in those channels.

plus one port diameter) as a result of using biomass feedstock. In the author’s experience, safe and

The higher the wall shear stress However, in using wide-gap plate heat proven fouling factors for plate heat

that the plate heat exchanger is de- exchangers, the engineer must con- exchanger design are 10% excess sur-

signed for, the greater the resistance sider the trade-off between the ability face area, also expressed as 10% safety

to “micro-fouling” due to fine particles, to handle fibers and larger particles margin, equivalent to approximately

scaling, crystallization or similar with the somewhat lower heat trans- (but not exactly) a cleanliness factor

surface mechanisms [3]. However, if fer coefficients that are a result of the of 90%. To better understand fouling

suspended particles are going to be lower wall shear in these more widely factors in plate heat exchangers and

of such a size that they may not be spaced channels. their relation to other terms for de-

able to pass through the corrugations In applications where large parti- scribing fouling, the author refers the

of the plate channels, then “macro- cles or fibers can be removed from the reader to Ref. [4].

fouling” (that is, plugging) of the heat fluids without affecting the process,

exchanger is a real concern. Here, the this should be done using static bas- Disproportionate flow ratios

engineer must compare the depth of ket strainers or automatic backwash- It is very common for the process en-

the plate groove (pressing depth) to able strainers upstream of the plate gineer who commonly selects shell-

the maximum diameter particle in the heat exchanger. and-tube heat exchangers to inad-

fluid stream. It is not recommended Biological fouling, typically when vertently design for disproportionate

to design plate heat exchangers to natural or untreated river, lake or flow ratios between hot and cold side

handle fluids containing particles ocean water is used as the coolant, can flows in a plate heat exchanger. This

with diameters greater than 75% of be a problem for all types of heat ex- is because shell-and-tube designs re-

the plate pressing depth. A good rule changers. As in the case of shell and quire high shell-side flows to create

of thumb is to keep particles below 2.5 tubes, the foulant and the fouling as much turbulence as possible on the

mm, although “deep groove” or “wide mechanism must first be identified, shell side. While these high shell-side

gap” plate designs are available from so that an effective solution such as flowrates allow the shell and tube to

many manufacturers that can tolerate strainers, inline injection of biocides run more efficiently (at the expense of

larger particles, up to 18 mm. or regular clean-in-place (CIP) proce- high pumping costs and water usage),

Fibers can be particularly problem- dures can be followed. using disproportionate flowrates when

atic in plate heat exchangers since the It should be noted that while heat specifying a plate heat exchanger will

same plate corrugations that create transfer surfaces of copper or copper- immediately eliminate the advantages

turbulence and high heat transfer cre- based alloys offer resistance to biological of high thermal efficiency and low cost

Chemical Engineering www.che.com February 2009 41

15_CHE_021509_GSO1.indd 41 1/22/09 11:47:31 AM](https://image.slidesharecdn.com/chemicalengineering200902-130204110833-phpapp02/85/Nano-Know-How-51-320.jpg)

![with a clip molded right into the gas- port can cause erosion and noise prob- Summary

ket itself (Figure 4). The advantage of lems. Steam velocities in excess of 100 As with all process equipment, know-

glue-free gaskets is that they are eas- m/s should be avoided. ing where, why and how to install the

ily removed and replaced in the field Secondly, the very high heat-trans- equipment in the proper application

by the operator, since there is no epoxy fer coefficients encountered when ensures good performance with expec-

glue or other adhesive bond that needs using plate heat exchangers in steam tations fulfilled for that equipment. A

to be broken in order to separate the heating service can result in small solid understanding of critical areas

gasket from the plate. heat-transfer areas and therefore in the design and selection of gasketed

However, there can be a problem relatively small plate packs. As a re- plate heat exchangers, as the author

with the glue-free gaskets in services sult, the fluid to be heated (typically has tried to outline in this paper, is no

where the heat exchanger is going to water) may experience an excessive exception to that philosophy.

be opened frequently for cleaning or pressure drop, and the heat exchanger Don’t hesitate to ask questions of

inspection. The glue free gasket is held will have to be oversized (typically by operating and maintenance personnel,

onto the plate by molded clips that are adding plates in parallel) to keep the who will be responsible for using the

spaced about 12 in. apart. If not careful water-side pressure drop within speci- equipment, about the nature of the flu-

during disassembly, the maintenance fied limits. This can add unnecessary ids, past experience with other types of

people may allow the gasket to stretch surface area and cost. heat exchangers in the intended service

if the portion between the clips sticks Thirdly, the small volume in the and other background that will make

onto the neighboring plate as the plate plate channel can lead to “stalling” as your installation successful. Make sure

pack is opened up. It is not possible to the steam present in the channels rap- that you consult with knowledgeable

get such a stretched gasket back into idly condenses and forms a vacuum. manufacturers with considerable expe-

the recessed groove it sits in. Vacuum formation followed by con- rience who can help you recognize and

In cases where frequent cleaning or densate build-up can create repeated avert design pitfalls. ■

inspection is anticipated, glued gas- water hammer, which can damage the Edited by Gerald Ondrey

kets, although a bit more expensive, heat exchanger and downstream equip-

will allow the plate pack to be opened ment. In this case, the design engineer Acknowledgements

and closed many, many times before the should look for plate heat exchangers The author wishes to acknowledge Bennat

Drazner, senior heat-transfer specialist at Alfa

gaskets need attention. In cases where offered by some manufacturers that are Laval, Inc. (Richmond, Va.) and also long-time

frequent opening is not expected but specifically designed for steam heating member of the HTRI Technical Committee, for

his proof-reading and many contributions to

where chemical or temperature attack service. These steam-heating plate ex- this paper.

of the gasket over time is a factor, glue- changers have large ports, short chan-

free gaskets should be considered since nel lengths and deep plate-pressing References

they can be quickly and easily replaced depths to avoid the problems described 1. Cooper, A., Suitor, J.W., Usher, J.D., Cooling

Water Fouling in Plate Heat Exchangers,

on a preventative maintenance basis. above for standard gasketed-plate heat Heat Transfer Engineering, January–March,

Plate gaskets, whether glued or exchangers in steam service. 1980.

glue-free, should have a life of sev- 2. Panchal, C.B., Fouling in Compact Heat Ex-

changers, Argonne National Laboratories.

eral years, unless they are in a service Flanged versus studded ports 3. Novak, L., “Fouling in Plate Heat Exchang-

where they are subject to chemical or There is no need to design or select ers and Its Reduction by Proper Design,” Alfa

Laval AB, Lund, Sweden.

oxidative attack or are running contin- plate heat exchangers with costly ex-

4. Kerner, J.W., Sizing Plate Heat Exchangers,

uously at their temperature limit. It is tended nozzles terminating in flanged Chem. Eng., November, 1993.

not at all necessary to replace plate connections. Almost all gasketed plate 5. Trom, L., Bergquist J-O. and Gromwell, J.,

“Higher Reliability Increases: Application

gaskets every time the unit is opened. manufacturers today use lined, stud- Available for Plate Heat Exchangers”, ASME

The author has installed plate heat ded ports. The lining is usually the HTD-Vol. 201, Book No. H00759-1992).

exchangers in modest temperature same material as the plate to prevent Author

(50–65°C), water-water service where the fluid from coming in contact with Jeff Kerner is president of

Alberts Associates, Inc.

the heat exchangers are still operat- the painted, carbon-steel frame. The (3070 Bristol Pike, Suite 216,

ing with the original gaskets after 20 studded-port connections present a Bensalem, PA 19020. Phone:

215–244–6350; Email: Jeff.

years. Well-designed gaskets sit in a raised-face or a flat-face ANSI bolt Kerner@albertsinc.com). He

recessed groove, and even when the pattern to the user’s field piping and has been providing heat trans-

fer solutions to the process

plate pack is fully tightened, the gas- have the advantage of no moment industry for over 30 years. A

kets are not excessively compressed arm to transmit nozzle loads. Linear chemical engineering gradu-

ate of The Cooper Union (New

enough to become damaged. loads (Fx, Fy, Fz) as well as bending York, N.Y.), he also received a

M.S.E. in ChE from the University of Michigan.

loads (Mx, My, Mz) are taken by the Previously, he worked at DuPont and Rohm

Steam heater service heavy steel frame and not by the Haas. Kerner has been active in the American

Institute of Chemical Engineers (AIChE), having

There are three points to look out for plates. Typical allowable port load- served as chairman of the Philadelphia subsection

when selecting plate heat exchangers ings for the plate heat exchanger with and on AIChE’s national committee on employ-

ment guidelines. He is a professional engineer

for steam heating service. First, when studded ports are much greater than registered in Pennsylvania, Delaware and New

using plate heat exchangers in this ap- those for the plate heat exchanger Jersey. He has authored or coauthored several pa-

pers on plate heat exchangers and speaks exten-

plication, high steam velocity in the with nozzled ports [5]. sively on heat transfer and process equipment.

Chemical Engineering www.che.com February 2009 43

15_CHE_021509_GSO1.indd 43 1/27/09 7:43:24 AM](https://image.slidesharecdn.com/chemicalengineering200902-130204110833-phpapp02/85/Nano-Know-How-53-320.jpg)

![Environmental Manager

Solids Processing

Eye-and-Face Personal

Protective

Equipment

Gateway Safety

Protecting the eyes and face in the workplace FIGURE 1.

Safety glasses help

shield eyes from impact hazards

is imperative to preventing the estimated

10–20% of work-related eye injuries OSHA compliance

that result in temporary or permanent vision loss OSHA defines minimum require-

ments for workplace PPE in Subpart I

of the Occupational Safety and Health

Victor J. D’Amato Standards for general industry em-

Atrium Environmental Health and Safety Services ployers (29 CFR 1910), which include

E

the chemical process industries (CPI).

ye injuries of all types occur relatively inexpensive compared to The general requirements of this stan-

at a rate of more than 2,000 the potential expense of an injury. But, dard include that employers select

per day in the U.S., and half no dollar figure can adequately reflect PPE for their employees based on the

of those occur in the work- the personal toll these accidents take hazards present in the workplace, and

place. In 2006, the U.S. Bureau of on injured workers. Prevent Blind- that employers train employees on the

Labor Statistics (BLS) reported over ness America estimates that 10–20% proper use and limitations of the PPE

52,000 workplace injuries to the eyes of work-related eye injuries result in selected for use. In November 2007,

and face, and approximately 70% of temporary or permanent vision loss. OSHA updated the standard to spe-

those were eye injuries [1]. The need This article outlines the basics of cifically require employers to pay for

to protect the face and eyes in the eye-and-face protection programs for the PPE required under the standard,

workplace is clear. plant operations, including key com- with some limited exceptions [3].

Implementing an eye-and-face pliance requirements and practical The OSHA Eye and Face Protection

protection program is important for information for personal protective Standard (29 CFR 1910.133) was estab-

several reasons. One is compliance. equipment (PPE) selection. lished specifically to protect employees

Between October 2006 and Septem- from eye and face hazards in the work-

ber 2007, more than 450 citations re- The causes of injuries place. To comply with this standard,

sulted in more than $215,000 in fines Most impacts to the face come from employers must ensure the following:

and penalties to manufacturers for flying objects, usually particulate 1. mployees who may be exposed to

E

failure to comply with the U.S. Occu- matter. When a particle hits the face it eye or face hazards from flying parti-

pational Safety Health Administra- might cause a cut or scratch, and the cles, molten metal, liquid chemicals,

tion (OSHA) standard for eye and face skin will repair itself over time given acids, caustic gases, vapors or poten-

protection [2]. proper medical attention. If the par- tially injurious light radiation use

Another reason is the cost of eye ticle hits the eye, it causes direct dam- appropriate eye or face protection.

and face injuries. The financial cost age, and it is far more difficult for the 2. mployees who may be exposed to

E

of these injuries is enormous and can eye to repair itself. a hazard from flying objects use

range from $300 to $3,000 per case. BLS reports that of the nearly 36,000 eye protection that provides side

More than $300 million per year is lost injuries to workers’ eyes in 2006, nearly protection.

in production time, medical expenses, 70% resulted from contact with objects 3. mployees who require prescrip-

E

and workers’ compensation according like flying particles, falling objects or tion lenses while engaged in op-

to OSHA. The return on investment sparks striking the eye. Contact with erations that involve eye haz-

for implementing an eye-and-face chemicals was responsible for the re- ards wear eye protection that

safety program is huge as its cost is maining 30% of eye injuries. incorporates the prescription in

48 Chemical Engineering www.che.com February 2009

17_CHE_021509_EM.indd 48 1/23/09 1:07:17 PM](https://image.slidesharecdn.com/chemicalengineering200902-130204110833-phpapp02/85/Nano-Know-How-58-320.jpg)

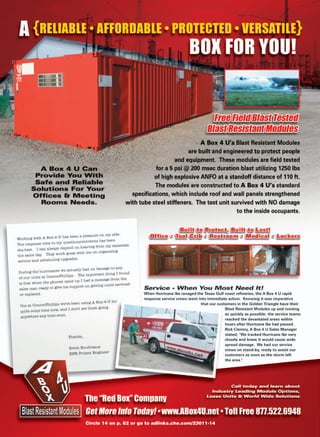

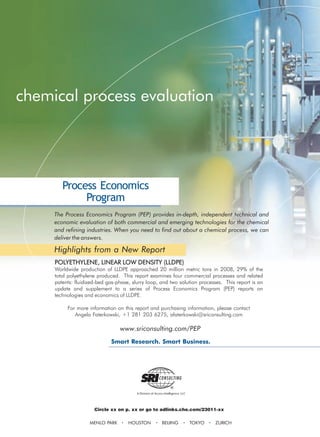

![Gateway Safety table 1. Hazard Assessment

Hazard type Examples of hazard Common related tasks

Impact Flying objects, such as Chipping, grinding, machining, masonry

large chips, fragments, work, wood working, sawing, drilling, chisel-

particles, sand and dirt ing, powered fastening, riveting and sanding

Heat Anything emitting ex- Furnace operations, pouring, casting, hot

treme heat dipping and welding

Chemicals Splash, fumes, vapors Acid and chemical handling, degreasing,

and irritating mists plating and working with blood

Dust Harmful dust Woodworking, buffing and generally dusty

conditions

Optical Radiant energy, glare Welding, torch-cutting, brazing, soldering and

radiation and intense light laser work

Source: U.S. Dept. of Labor, Occupational Safety Health Administration (OSHA), Eye and

FIGURE 2. Face Face Protection eTool, http://www.osha.gov/SLTC/etools/eyeandface/ppe/selection.html

shields protect the

entire face, but do not 2. dentify the sources of the haz-

I may have been manufactured to

protect the eyes from ards. Talk to employees as they meet earlier editions of ANSI Z87.1.

impact hazards when

worn alone. Safety glasses know best about their trades, OSHA requires that eye and face

or goggles should also be worn work areas and processes. PPE purchased after July 1994 be

Consider all possible hazards, manufactured to meet the 1989 edi-

even those that seem minor or tion of ANSI Z87.1.

its design, or that they wear eye unlikely. Some examples of eye and Eye and face PPE that meets the cri-

protection that can be worn over face hazards and typical sources are teria specified in ANSI Z87.1 must be

the prescription lenses without summarized in Table 1. marked with a manufacturer’s unique

disturbing the proper position of 3. rganize the data collected. De-

O marking and the “Z87” marking. Spe-

the prescription lenses or the pro- velop a table or spreadsheet listing cial purpose lenses and shaded lenses

tective lenses. the occupations, work areas, and must also be marked indicating the

4. Eye-and-face personal protective

processes you identify, the hazards purpose and shade. Eye and face PPE

equipment is distinctly marked so identified in each category, and the must be selected based on the hazards

that the manufacturer is clearly sources of the hazards. identified in the hazard assessment.

identified. 4. nalyze your data, considering the

A Some examples of the types of protec-

5. mployees who may be exposed

E probability and severity of each tion available for hazards are summa-

to injurious light radiation during hazard. Keep in mind that mul- rized in the next sections.

work process, such as welding, ther- tiple hazards and sources may be Ultimately, the eye and face pro-

mal cutting, brazing, torch solder- present. This will help in deciding tection must be comfortable to wear

ing, and using lasers, use eye protec- which PPE is appropriate. and not interfere with the employee’s

tion equipped with filter lenses that 5. ertify your assessment. OSHA re-

C work. Poor-fitting PPE will not afford

have a shade number appropriate quires that every employer verify its the necessary protection, may be un-

for the work being performed. assessment, identifying the areas comfortable to wear, and may not get

assessed, who performed the assess- used. Since eye-and-face protection

implementation ment, and the dates it was performed. devices can come in different sizes,

Implementing a practical, effective 6. eview and update your assessment

R care should be taken to ensure that

PPE program includes the following on a routine basis, or if changes in the the right size is selected.

straightforward steps, which are de- workplace or processes are planned. Impact hazards. Safety spectacles

scribed in more detail below. (Figure 1) are intended to shield the

1. Assess the workplace for hazards. PPE selection wearer’s eyes from impact hazards,

2. Select PPE based on these hazards. The American National Standards such as flying fragments, objects,

3. Train workers on proper PPE use. Institute (ANSI) standard for eye and large chips, and particles. Workers

4. Determine how prompt emergency

face protection (Z87.1) sets forth cri- are required to use eye safety spec-

care will be provided in the event of teria related to the description, gen- tacles with side shields when there is

an accident. eral requirements, testing, marking, a hazard from flying objects. Non side-

selection, care and use of eye and face shield spectacles are not acceptable

Hazard assessment PPE in the workplace. The 2003 edi- eye protection for impact hazards. The

OSHA provides guidance on conduct- tion specifies requirements for safety selection of safety glasses is almost in-

ing hazard assessments, which are glasses, safety goggles, face shields finite as a host of manufacturers have

summarized as follows [4]. and full-face and hooded respirators. stepped up to meet employee demand.

1. he first step in the hazard assess-

T This ANSI standard is revised and Safety goggles are also intended to

ment for eye and face protection is updated routinely to reflect current shield the wearer’s eyes from impact

to walk through your facility and technologies and the current state of hazards. Goggles fit the face immedi-

identify the potential hazards that practice. While most PPE manufac- ately surrounding the eyes and form

can injure the eyes or face. Hazards turers have adopted the 2003 edition a protective seal around the eyes. This

should be assessed by occupation or of the standard in new products, eye prevents objects from entering under

trade, work area and work activity. and face PPE currently being used or around the goggles.

Chemical Engineering www.che.com February 2009 49

17_CHE_021509_EM.indd 49 1/23/09 1:08:35 PM](https://image.slidesharecdn.com/chemicalengineering200902-130204110833-phpapp02/85/Nano-Know-How-59-320.jpg)

![Environmental Manager

Face shields (Figure 2) are intended presents additional hazards

to protect the entire face or portions of to contact lens wearers. Safety

it, but they do not protect employees’ goggles should be worn when

eyes from impact hazards when worn dust is present. Safety goggles

alone. Face shields should be used in are the only effective type of eye

combination with safety spectacles or protection from nuisance dust.

goggles for additional protection. Face- Optical radiation hazards.

shield windows are made of varying Welding, thermal cutting, braz-

types of transparent materials and ing, laser work and similar

in varying thicknesses, both of which operations create intense con-

should be considered when selecting centrations of heat, ultraviolet,

face shields for specific tasks. Window infrared, and reflected-light ra-

and headgear devices are available in diation. Some of these activities

various combinations to be compatible can produce optical radiation

with other PPE, such as hardhats. intensities greater than those

Welding shields (Figure 3) provide experienced when looking di-

eye and face protection from flying rectly at the sun. Unprotected

particulate matter during welding, exposure may result in eye in-

thermal cutting and other hot-work juries including retinal burns,

activities. These shields are typically cataracts, and permanent blind-

equipped with shaded lenses that pro- ness. Many lasers produce invis-

vide protection from optical radiation. ible ultraviolet, and other forms

Heat hazards. Working with heat of non-ionizing radiation. FIGURE 3. Welding shields are typically equipped

with shaded lenses to protect from optical radiation

requires goggles or safety spectacles The OSHA standard (29 CFR

with special-purpose lenses and side 1010.133) includes a table that lists Institute for Occupational Safety

shields. However, many heat-hazard the minimum shade requirements and Health (NIOSH) issued a Cur-

exposures require the use of a face for eye protection during industrial rent Intelligence Bulletin (CIB) on

shield in addition to safety spectacles processes that generate optical radia- the use of contact lenses in chemical

or goggles. When selecting PPE, con- tion. The selection of eye protection for environments. In this CIB, NIOSH

sider the source and intensity of the lasers should depend on the lasers in recommends that workers be permit-

heat and the type of splashes that may use and the operating conditions, and ted to wear contact lenses when han-

occur in the workplace. should be consistent with the laser dling hazardous chemicals provided

Chemical hazards. Safety goggles manufacturer’s specifications. that certain safety guidelines are fol-

(Figure 4) protect the eyes, eye sock- PPE and prescription lenses. If lowed and that contact lenses are not

ets, and the facial area immediately employees wear reading glasses with banned by regulation or contraindi-

surrounding the eyes from a vari- basic magnification, ANSI-approved cated by medical or industrial hygiene

ety of chemical hazards. The protec- safety glasses and goggles with read- recommendations. OSHA recommends

tive seal formed around the eyes is ing magnifiers in the lenses are an op- against contact-lens use when work-

especially important when work- tion. It’s also possible to buy prescrip- ing with certain chemicals, including

ing with or around liquids that may tion safety glasses and goggles that acrylonitrile, methylene chloride, 1,2

splash, spray or mist. Several kinds are compliant with the ANSI stan- dibromo-3-chloropropane, ethylene

of cover-type goggles are available: dard. ANSI-compliant goggles and oxide and methylene dianiline.

direct vented, indirectly vented or safety glasses are also available to fit The NIOSH recommendations are

non-vented. It’s important to select over prescription glasses; but, they specifically intended for work with chem-

the right type. Vented goggles, for can be uncomfortable and less likely ical hazards, and do not address hazards

example, may be less effective in pro- to be worn. from heat, radiation, or high-dust or

tecting the eyes from splashes and Wearing contact lenses under some high-particulate environments [5].

respiratory aerosols than non-vented circumstances provides workers with Usable life of PPE. All PPE has a

or indirectly vented goggles. a greater choice of eye and face pro- usable lifespan. Most manufacturers

Face shields are intended to protect tection and better visual acuity. How- recommend how frequently eye-and-

the entire face from a variety of chemi- ever, the risk of injury to the eye from face protection equipment should be

cal hazards, particularly when pour- chemical exposure is unknown for con- replaced. If the PPE becomes dam-

ing chemicals or where splashes may tact lens wearers compared with non- aged or distorted, it must be replaced

occur. Face shields are considered sec- wearers working with chemicals. It is to work properly. As far as the usable

ondary protection and must be used in important to note that contact lenses life of a product, a good rule of thumb

addition to safety goggles to provide are not eye protective devices, and is if your safety glasses are more than

adequate protection. wearing them does not reduce the re- five years old, they may not be compli-

Dust hazards. Working in a dusty en- quirement for eye and face protection. ant with the latest ANSI standards, so

vironment can cause eye injuries and In June 2005, the U.S. National you should get a new pair.

50 Chemical Engineering www.che.com February 2009

17_CHE_021509_EM.indd 50 1/23/09 1:10:43 PM](https://image.slidesharecdn.com/chemicalengineering200902-130204110833-phpapp02/85/Nano-Know-How-60-320.jpg)