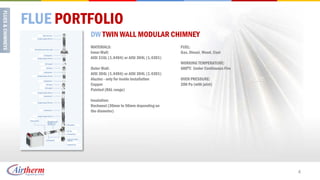

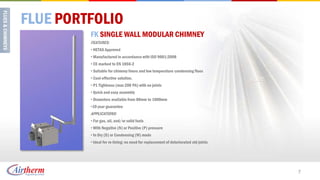

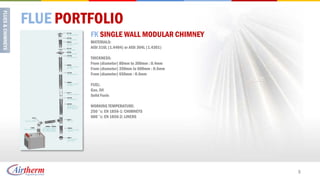

Airtherm is an HVAC specialist with 54 years of combined experience, offering a variety of high-quality flue and chimney systems. Their products, designed for various applications including domestic and commercial heating, adhere to strict regulations and safety guidelines, and come with guarantees up to 10 years. The company emphasizes quality workmanship and customer feedback while maintaining competitive pricing in the market.