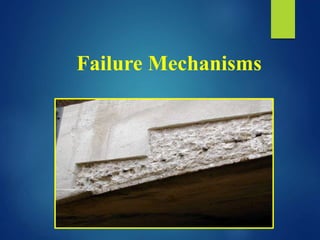

This document discusses improving the compatibility and curing of wood-cement composites. Several methods are described to enhance compatibility, including pre-treating wood to remove soluble compounds, adding cement setting accelerators like calcium chloride, and coating wood particles prior to mixing with cement. The document also discusses using carbon dioxide injection, magnesium oxychloride cement instead of Portland cement, and adding fumed silica to improve properties. Failure mechanisms of wood-cement composites like fiber fracture and pull-out are examined.