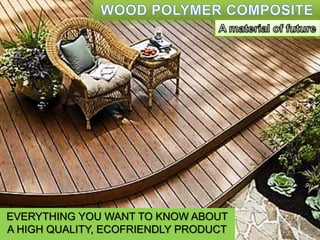

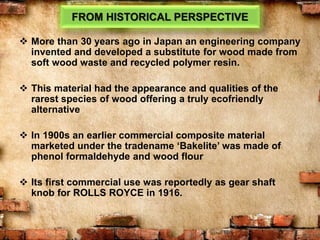

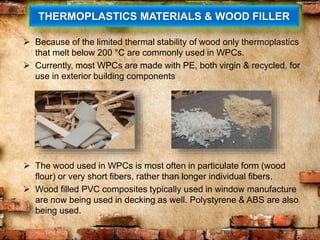

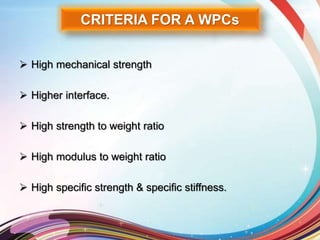

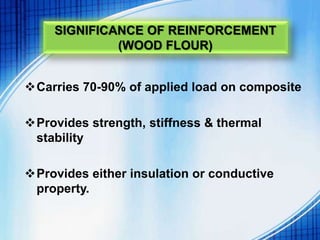

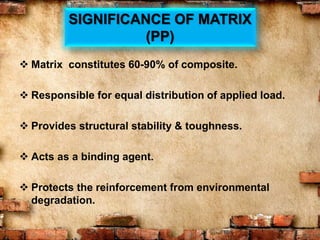

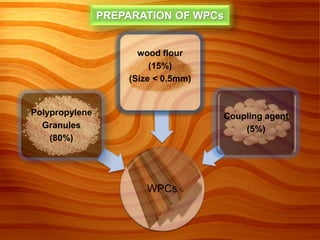

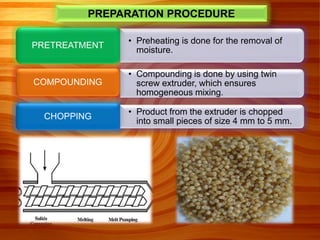

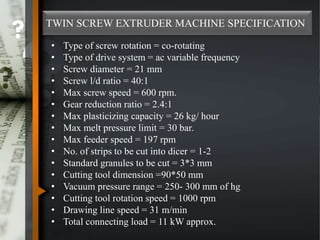

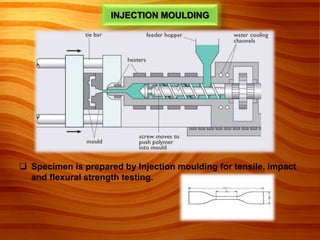

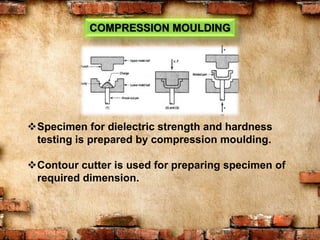

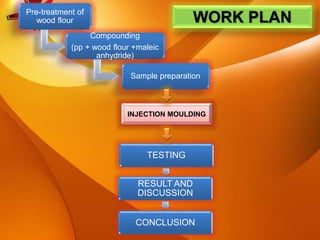

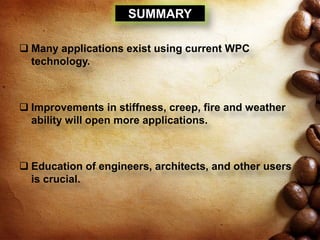

This document discusses wood plastic composites (WPCs). It provides details on their composition, manufacturing process, properties, applications and advantages. WPCs are made from wood flour/fibers combined with thermoplastics using an extrusion process. They have properties similar to wood but are more durable, weather resistant and require no painting. Common applications include decking, railings and outdoor furniture due to their sustainability and durability.