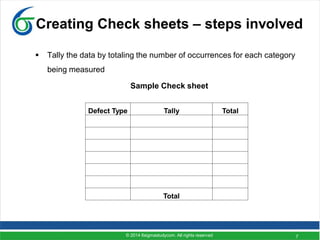

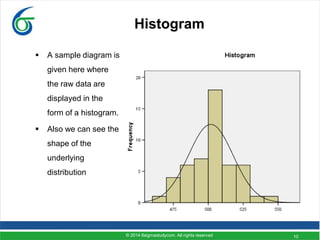

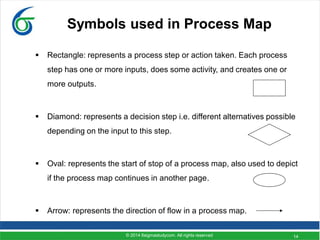

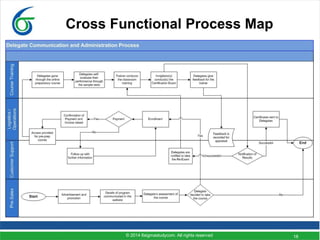

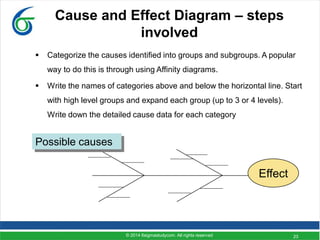

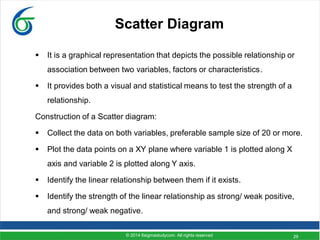

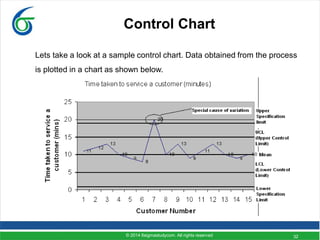

The document provides an overview of quality tools used in Six Sigma. It describes the seven basic quality tools: check sheets, flow charts, histograms, cause-and-effect diagrams, Pareto charts, scatter diagrams, and control charts. It explains how to create and interpret each tool. Check sheets are used to collect data, flow charts map processes, and histograms show data distribution. Cause-and-effect diagrams identify potential causes, Pareto charts rank problems, and scatter diagrams show relationships. Control charts distinguish common and special causes of variation.