The document discusses factors related to casing design, including:

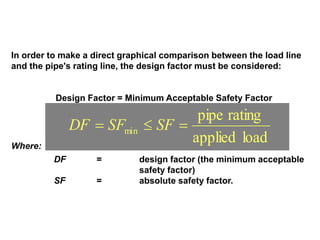

1) The design factor is the minimum acceptable safety factor, which is the ratio of the load applied to the pipe's rating.

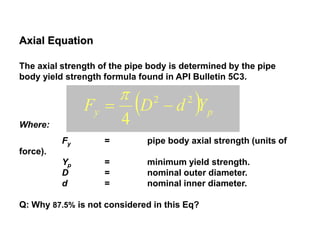

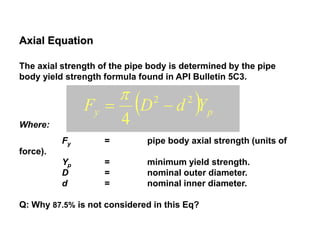

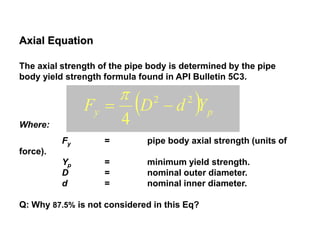

2) The axial strength of the pipe is determined by an equation using the pipe's minimum yield strength, outer diameter, and inner diameter.

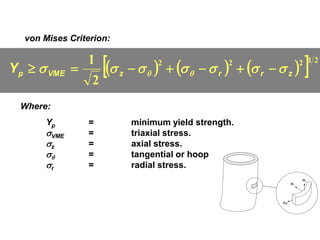

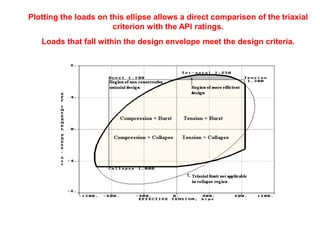

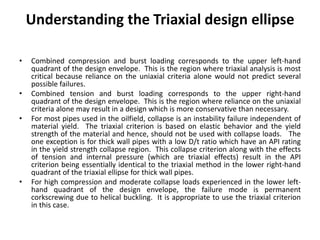

3) A triaxial stress criterion using three stress components - axial, tangential, and radial - is presented for evaluating combined loading conditions. Loads falling within the resulting design envelope meet the design criteria.