This document summarizes quality control and site execution activities on a construction project. It includes 3 sections:

1. Quality control testing results like cube tests showing the concrete met the required compressive strength. Lab tests were performed for mix design, slump, and compressive strength.

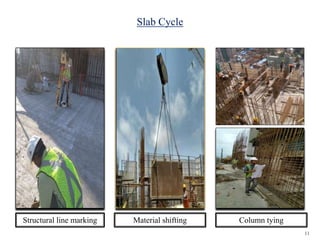

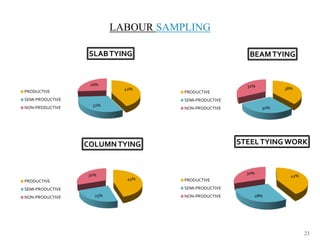

2. Details of site execution activities for different construction elements like pile foundations, coupling beams, slabs, and formwork installation. Labour productivity rates for different crews are provided.

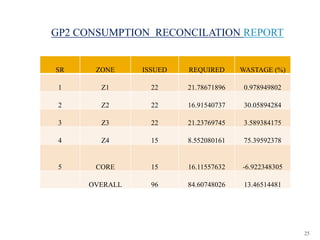

3. Material consumption data is summarized showing wastage rates for curing compound and grout were higher than expected, suggesting issues with workmanship. Suggestions are provided to address these issues through better work planning and resource coordination.