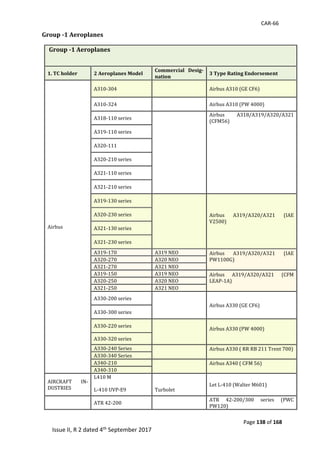

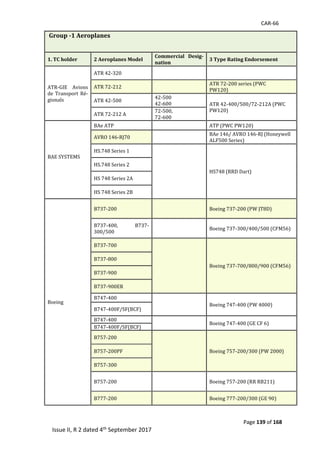

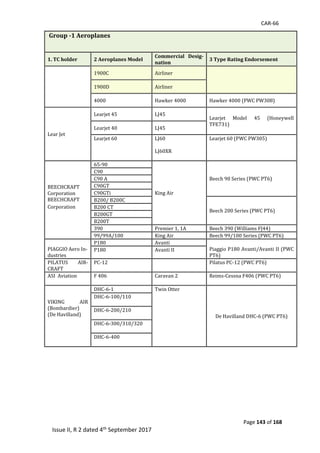

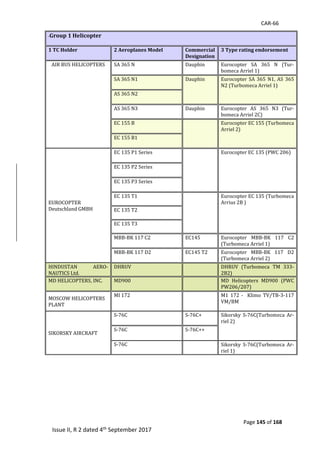

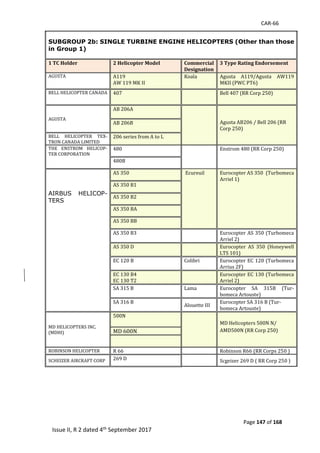

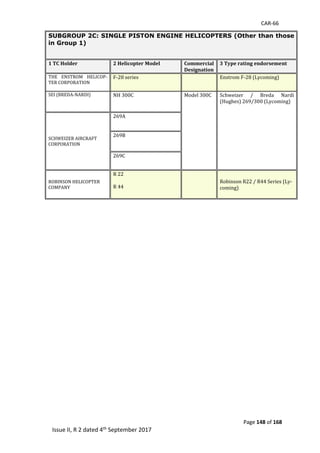

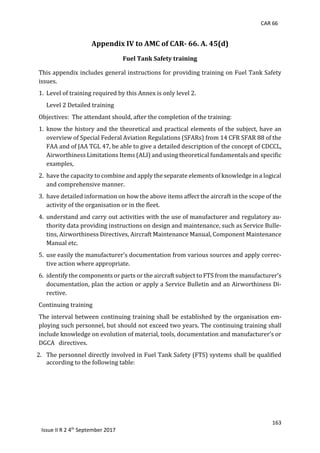

This document provides the requirements for licensing aircraft maintenance engineers in India. Some key points:

- It details the requirements to obtain an Aircraft Maintenance Engineer's Licence, including basic knowledge, experience, endorsement with aircraft ratings, limitations, and conversion provisions.

- Licenses will be available after conversion of existing licenses or obtaining a fresh license by passing basic knowledge examinations.

- The licensing system is being harmonized with EASA Part 66 to standardize aircraft maintenance personnel licensing.

- It defines various license categories and groups aircraft based on similarities to simplify type training and ratings. Requirements include modular basic examinations, type training, and practical demonstrations of skills.

![CAR-66

Page 2 of 168

Issue II, R 2 dated 4th September 2017

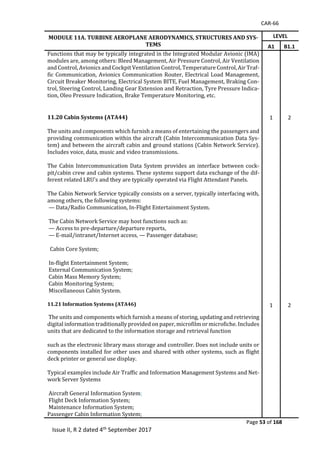

Salient Features of the CAR-66

The CAR-66

has been drafted in line with the current Rule 61 and to harmonise the aircraft

maintenance personnel licensing system with EASA Part 66 ( General).

details, requirements for qualifying an individual to obtain an Aircraft Maintenance

Engineer’s Licence and extension of such licence [CAR-66]

eliminates the system of obtaining Airframe, Engine, Electrical, Instrument and Ra-

dio System Licences separately [66.A.03]

redefines the syllabus for basic knowledge examination in modular pattern

[66.A.25]

provides for endorsement of an AME licence after successful completion of type

training and the type training examination/type examination which shall consist of

both theoretical and practical examinations [66.A.45 (c)]

lists the details of practical tasks to qualify an individual to obtain a type rating [Ap-

pendix II to AMC]

provides for acquiring group type rating of aircraft and certification privileges

[66.A.45 (a)]

has a provision to convert the existing AME licence to CAR 66 licence [66.A.70] with

or without limitation.](https://image.slidesharecdn.com/car66issue2rev-180321013801/85/Car-66-issue2-rev-2-170904-2-320.jpg)