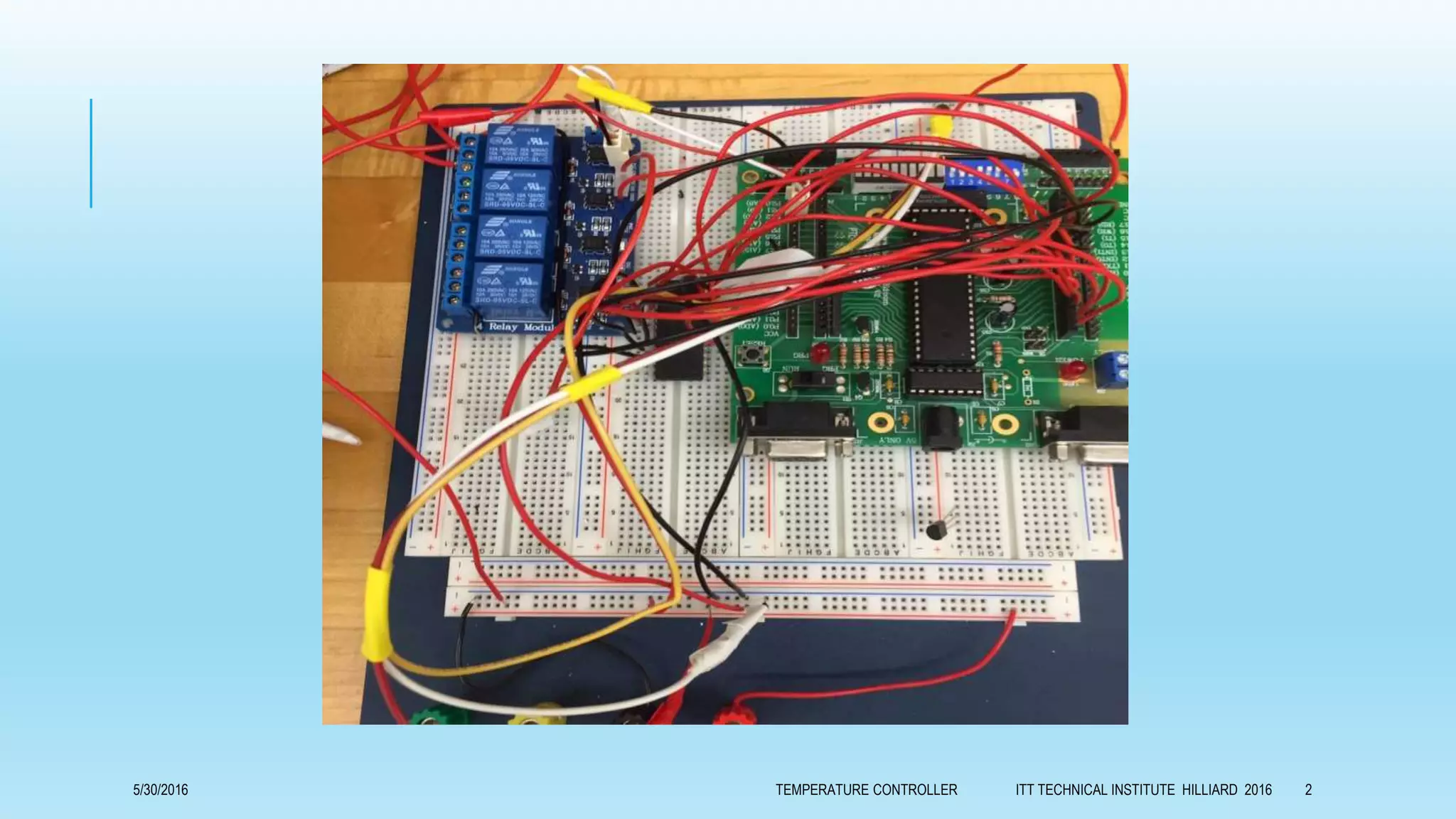

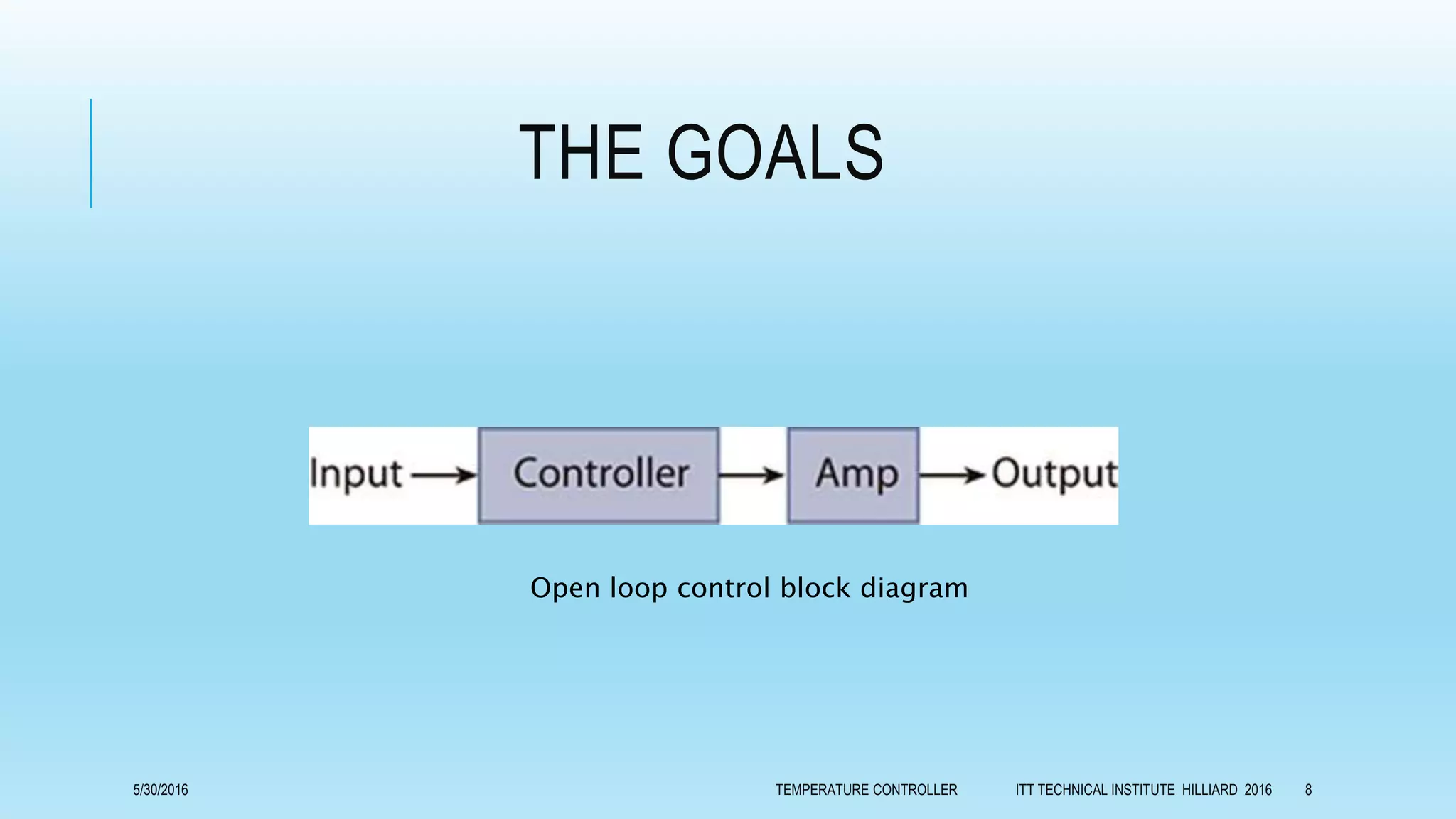

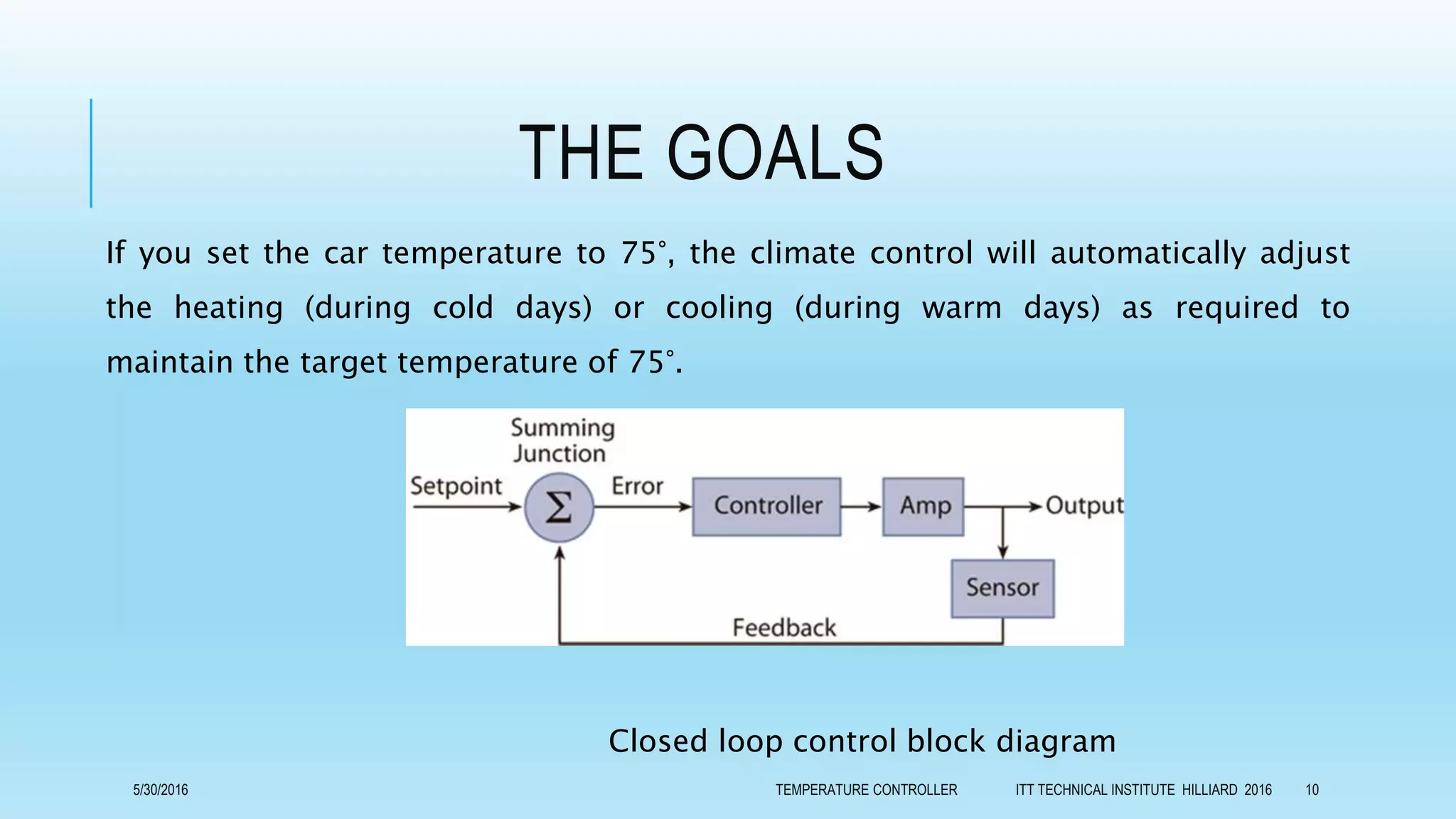

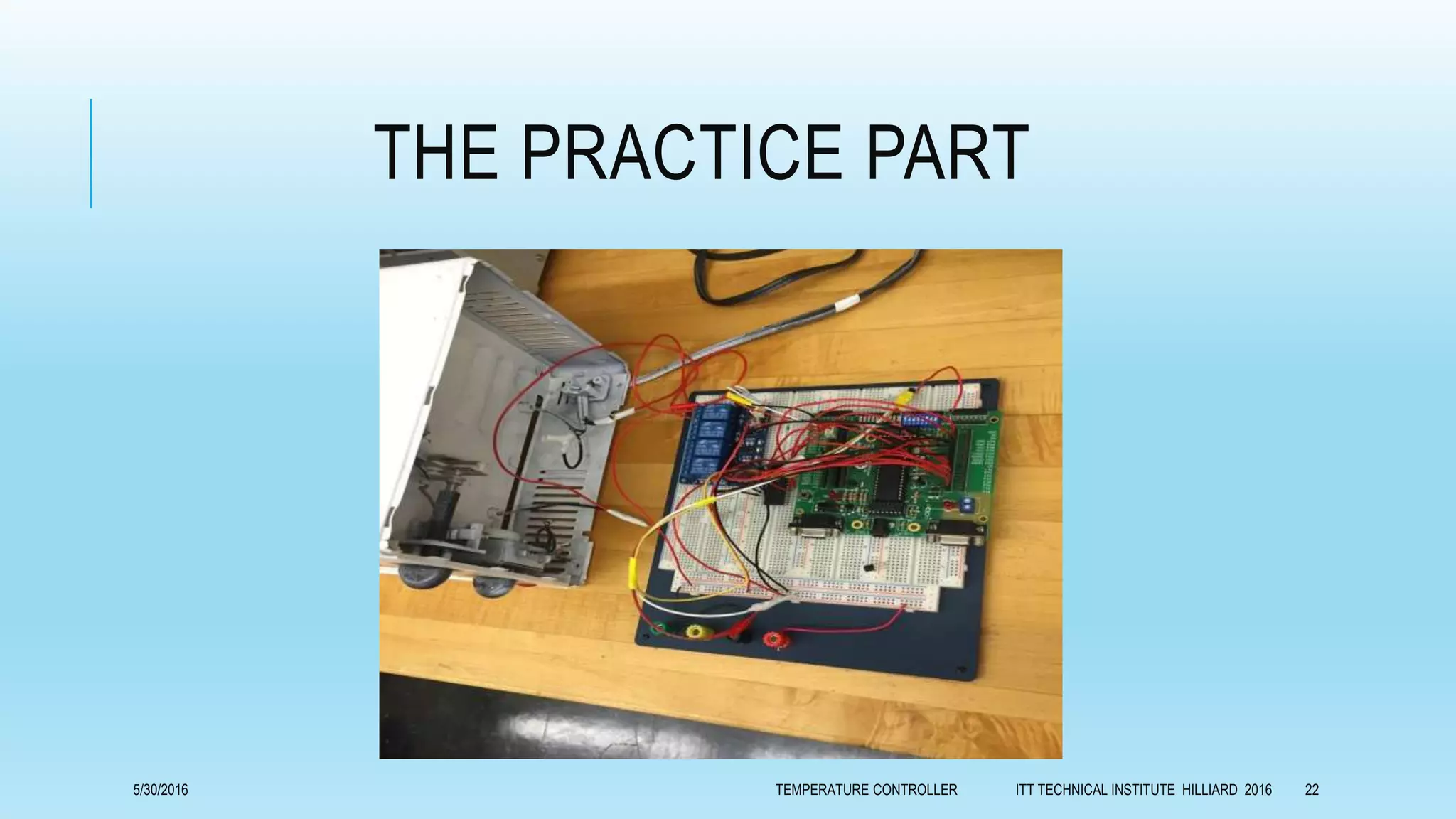

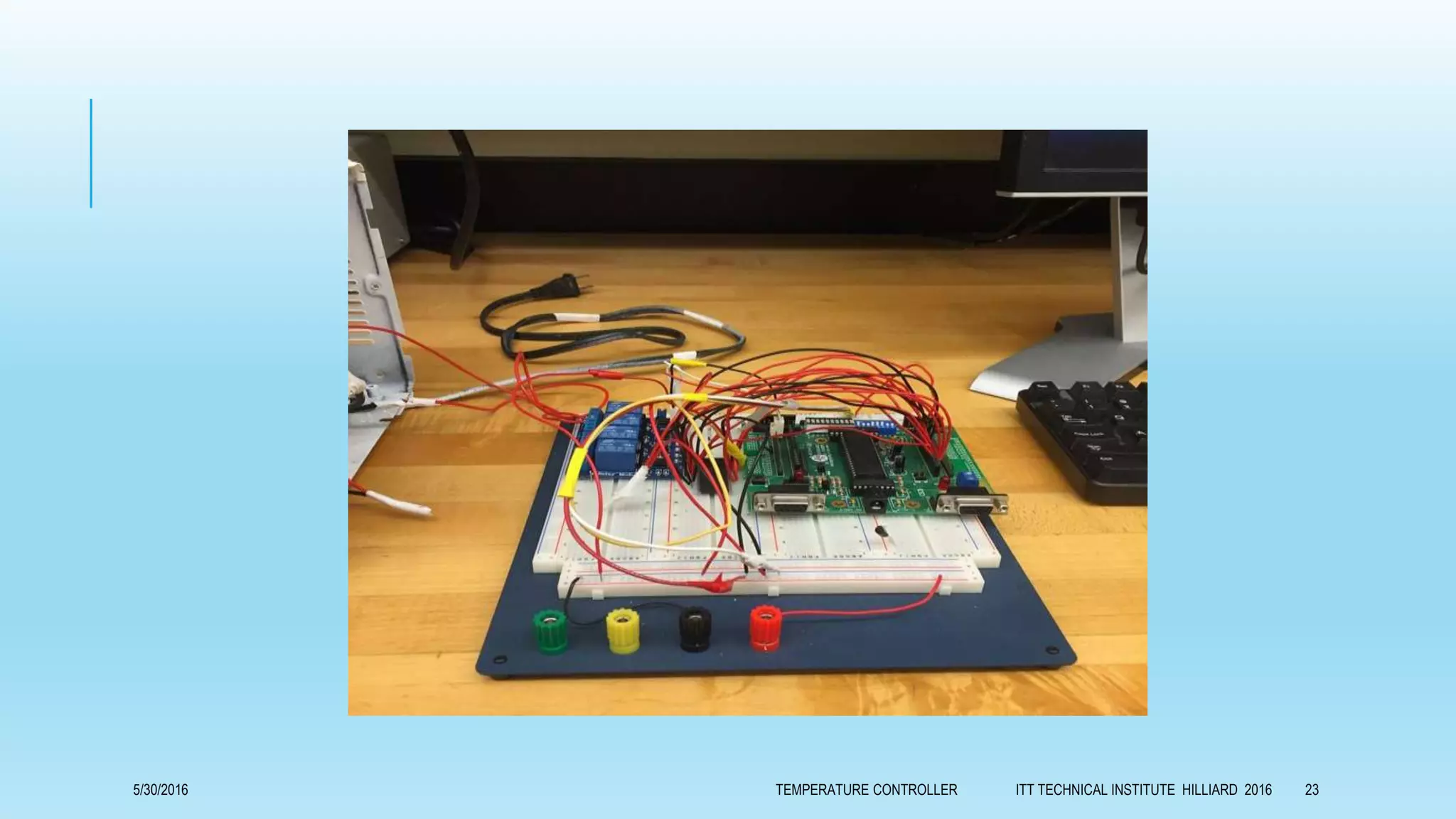

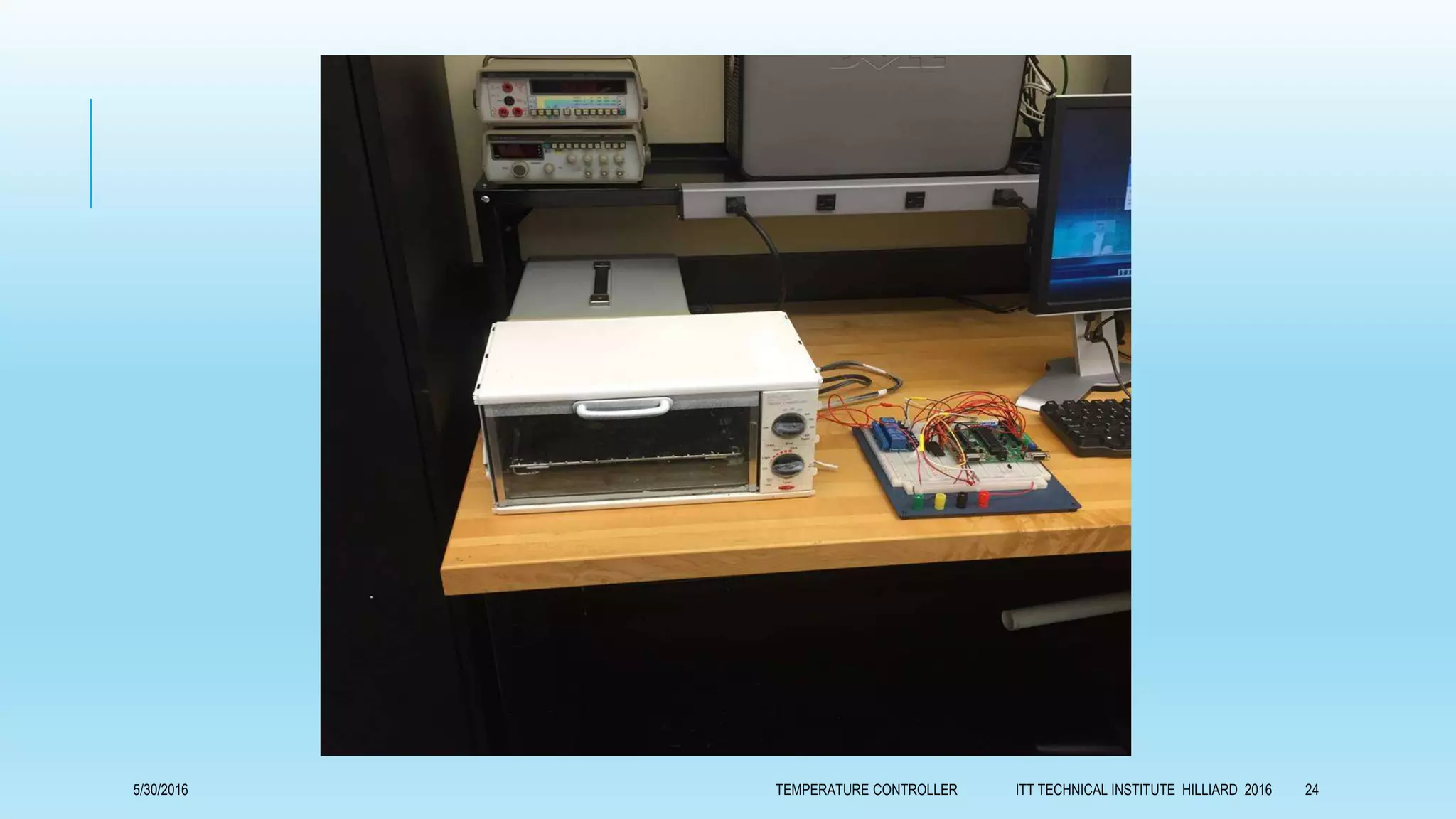

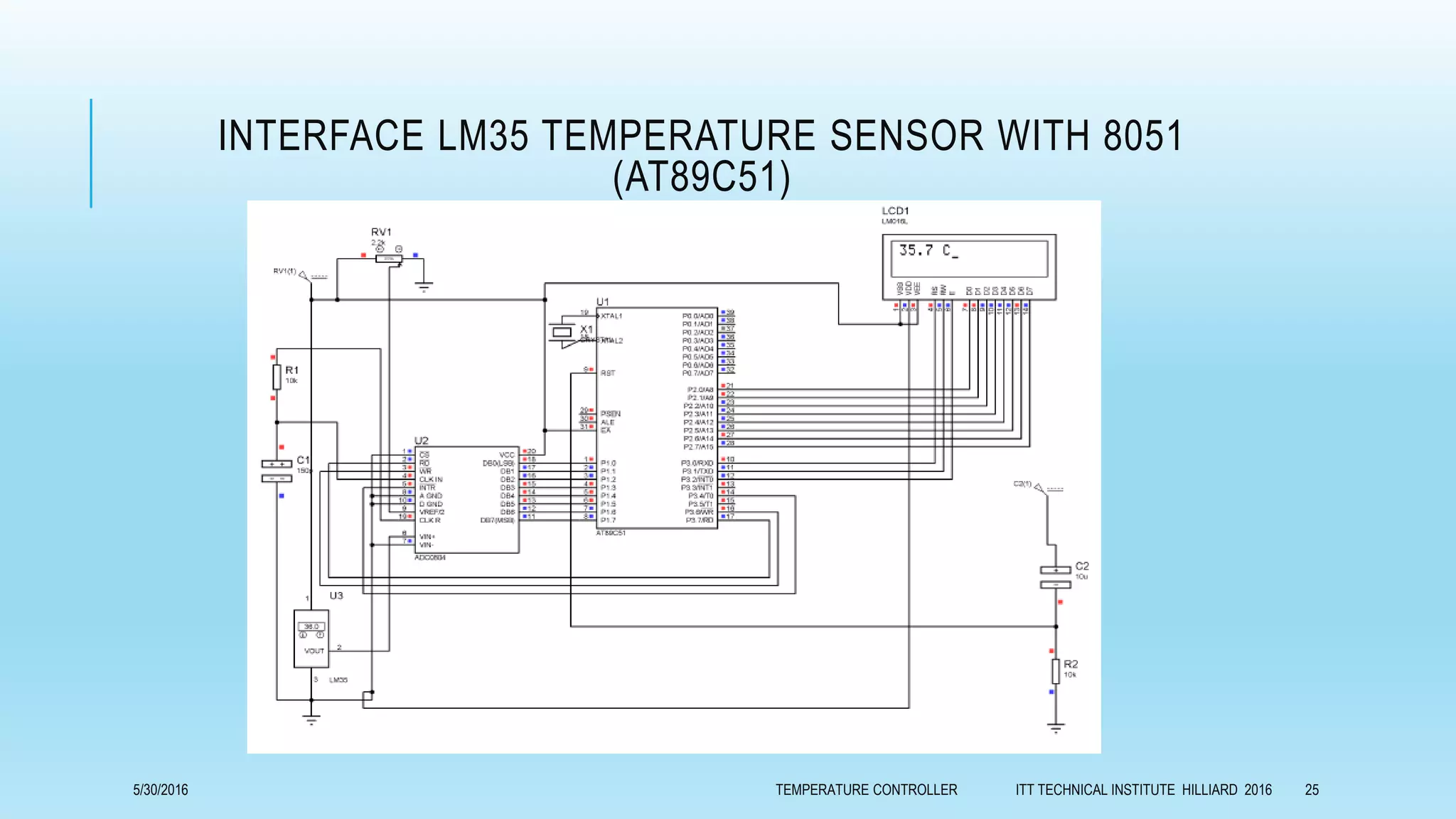

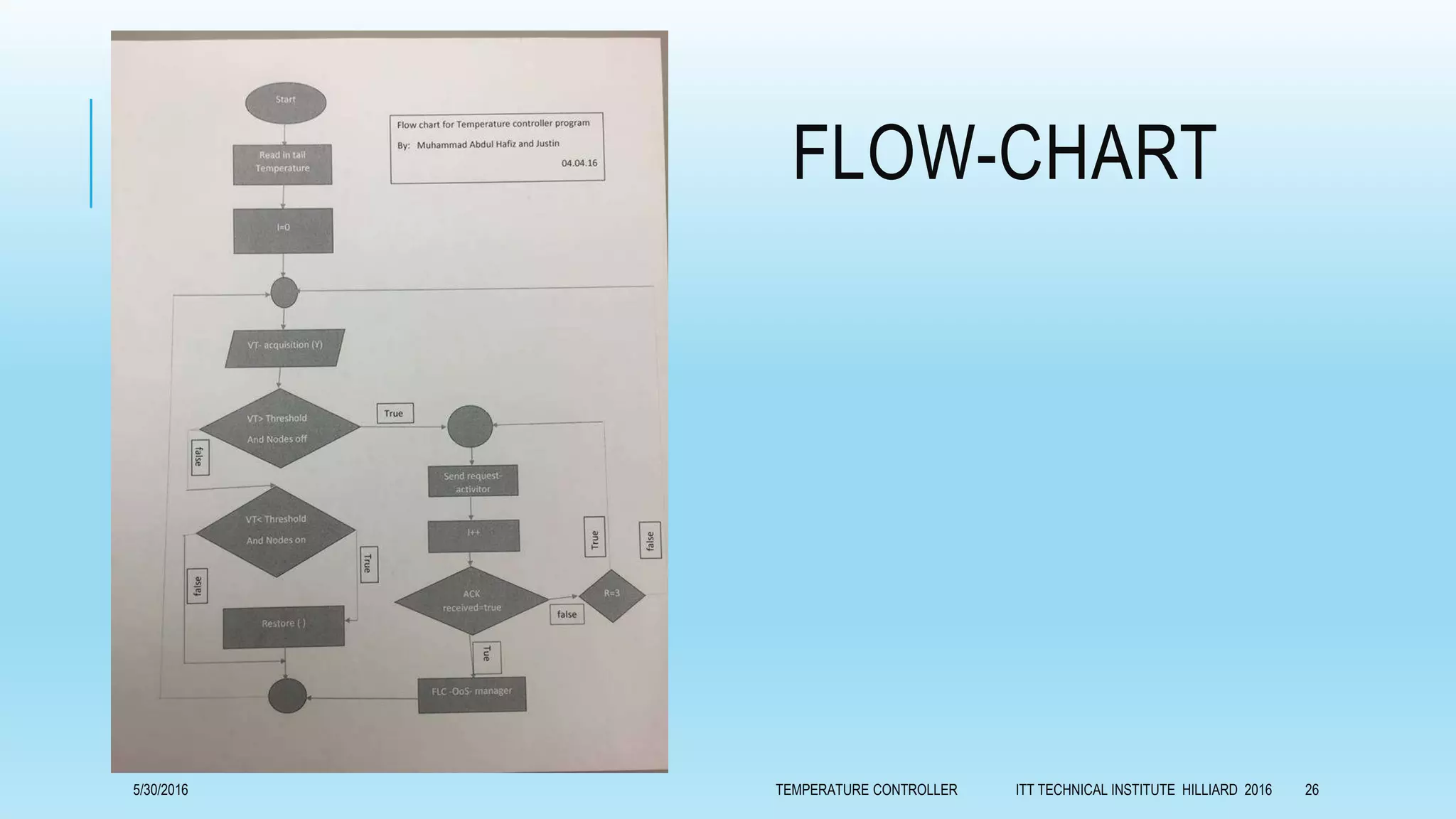

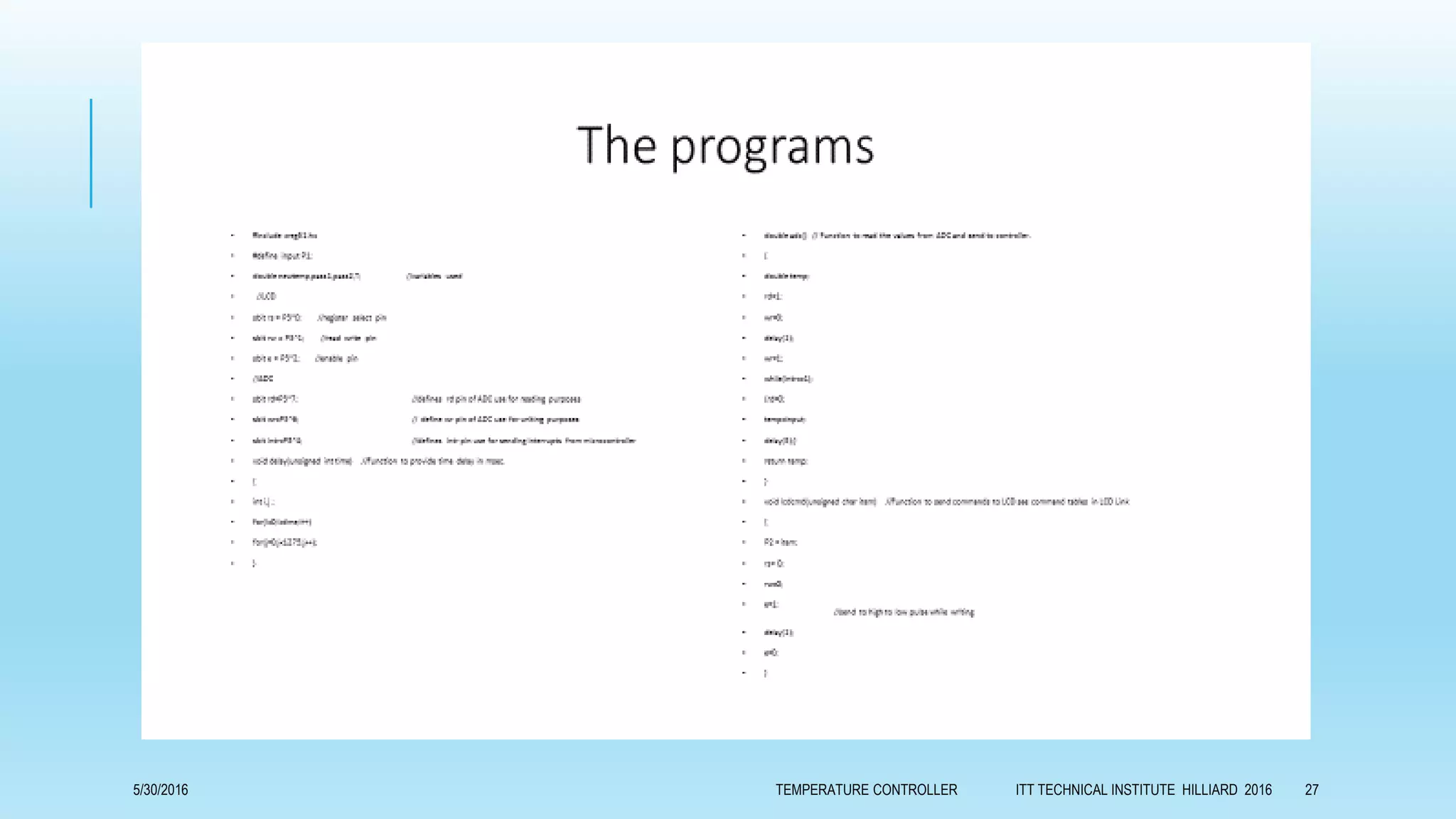

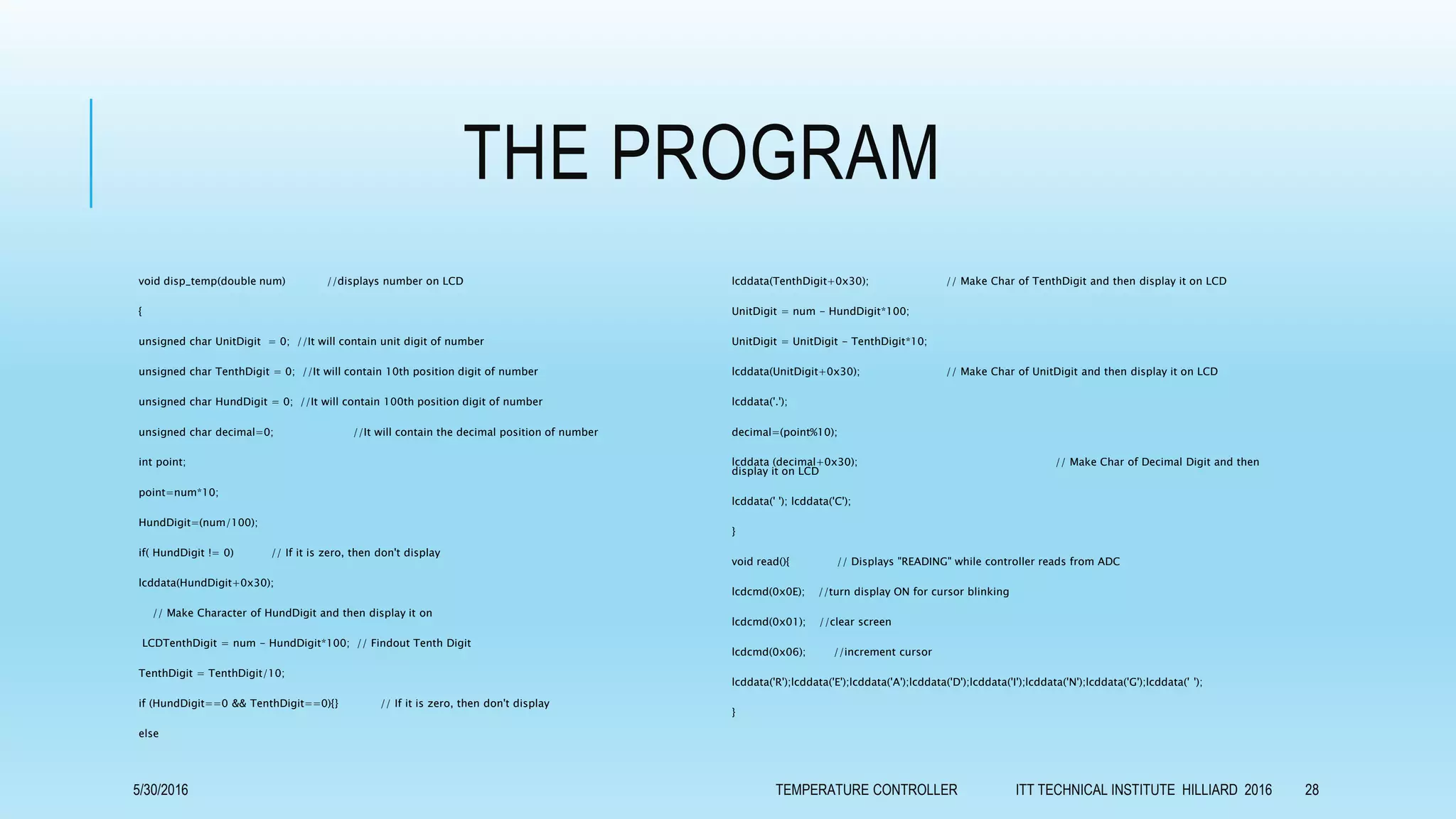

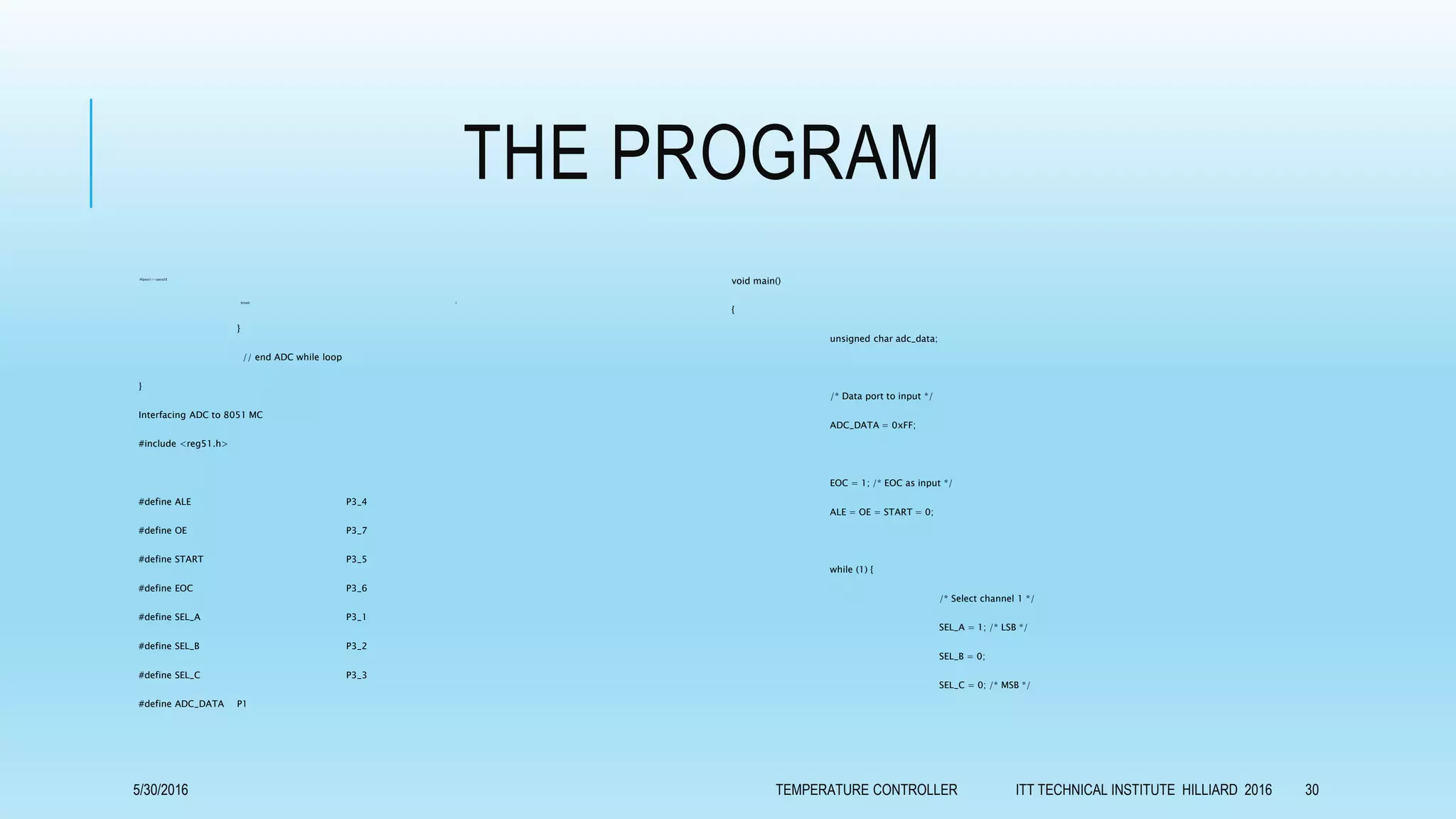

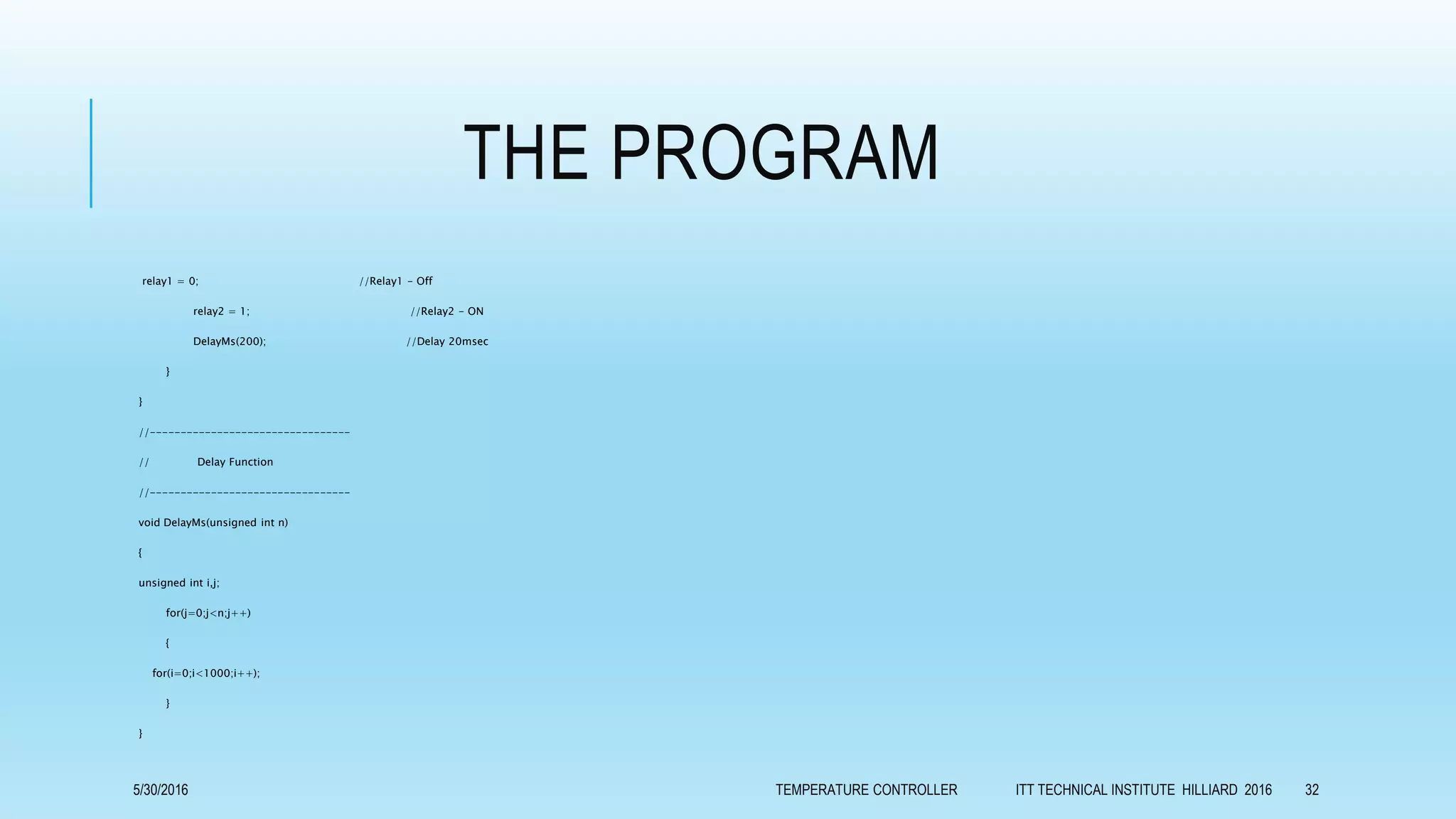

This document describes a student capstone project to create a generic temperature controller. It will use a microcontroller to monitor temperature using a sensor and control heating and cooling elements to maintain a set temperature. The goals are to achieve closed-loop temperature control and maintain a stable temperature regardless of environmental changes. It discusses the components, inputs, outputs, programming, and benefits of the temperature controller. The students aim to complete the hardware and software in six weeks to allow temperature control for laboratory and industrial applications.