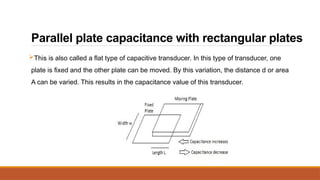

Capacitive transducers are sensors that measure changes in capacitance to detect various physical parameters such as displacement, pressure, and humidity. They operate on the principle of variable capacitance, with movable plates allowing for changes in distance and area that affect capacitance. Capacitive transducers are advantageous due to their high sensitivity and accuracy but can be sensitive to temperature and humidity.