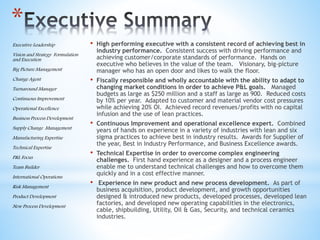

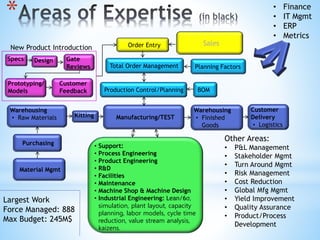

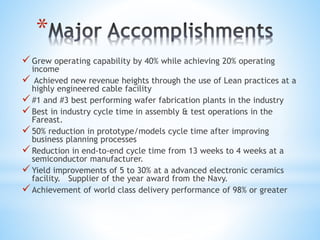

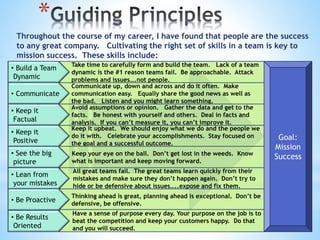

Mark Cortazzo is a high-performing executive with a consistent record of achieving best-in-industry performance across various industries such as electronics, utilities, oil and gas, and shipbuilding. He has expertise in operational excellence, continuous improvement, manufacturing, engineering, and turning around underperforming businesses. Cortazzo has managed large budgets and staff, implemented lean practices, and reduced costs while improving profits. He holds degrees in engineering and business management and certifications in project management and Lean Six Sigma.