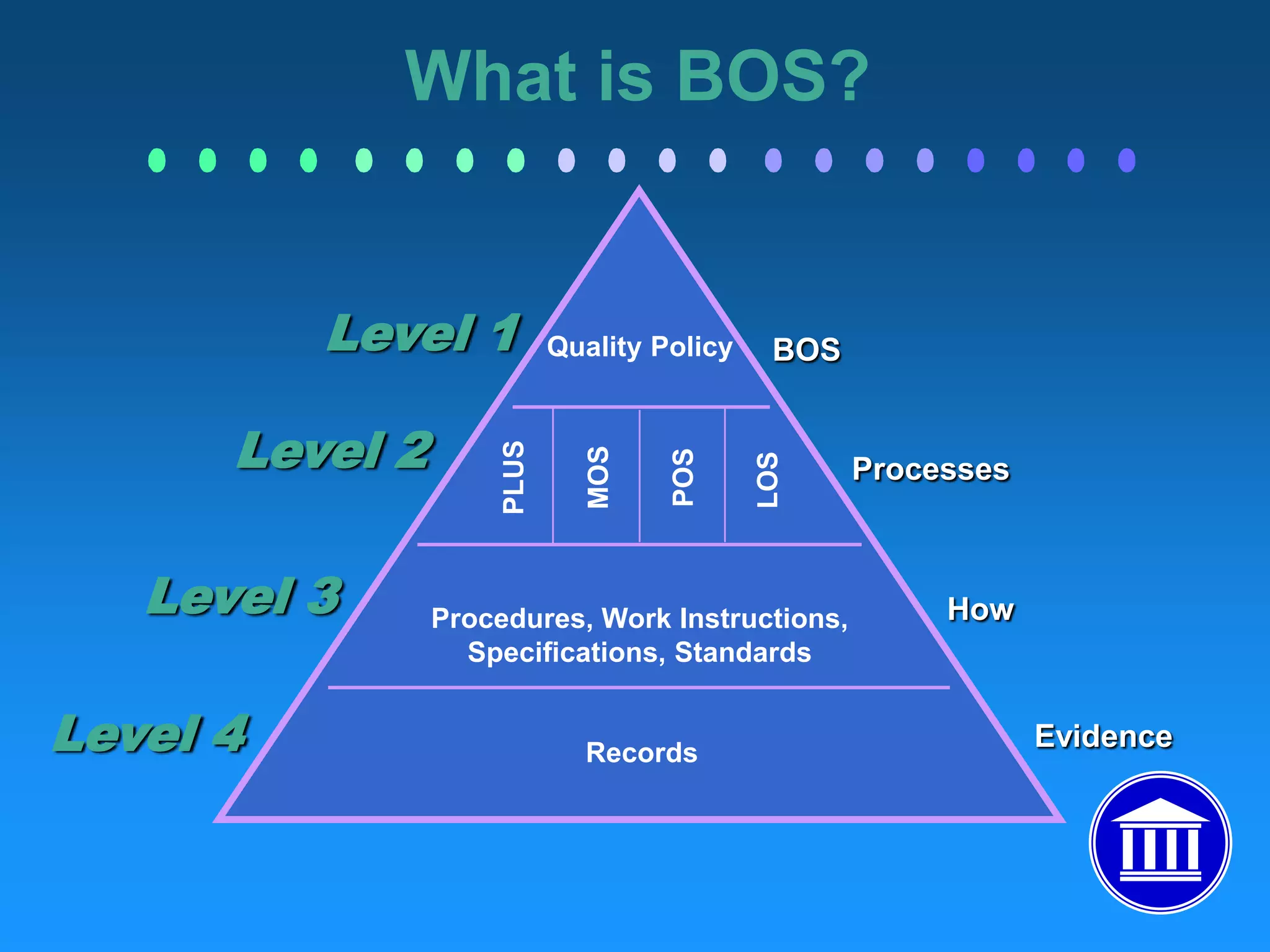

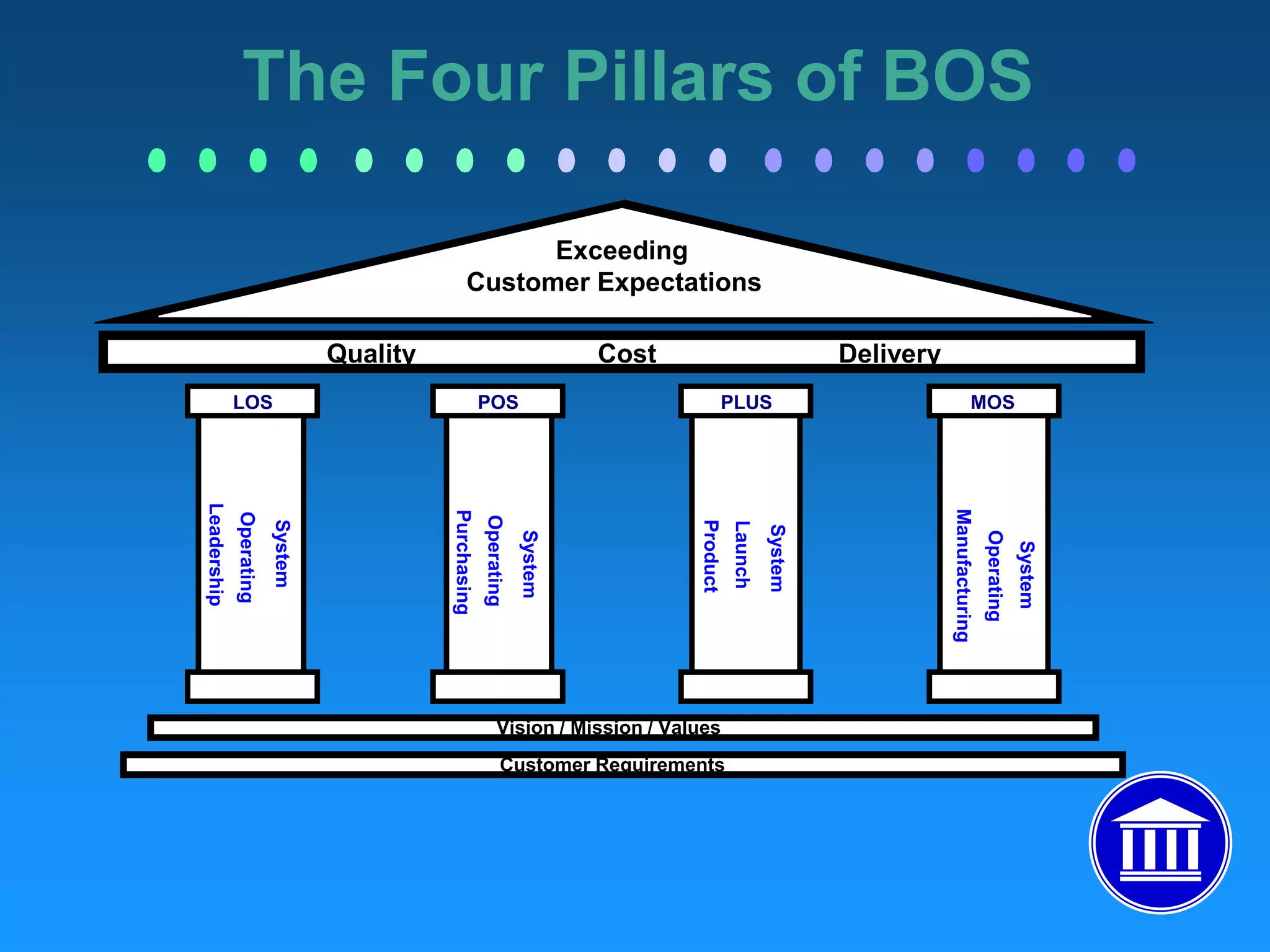

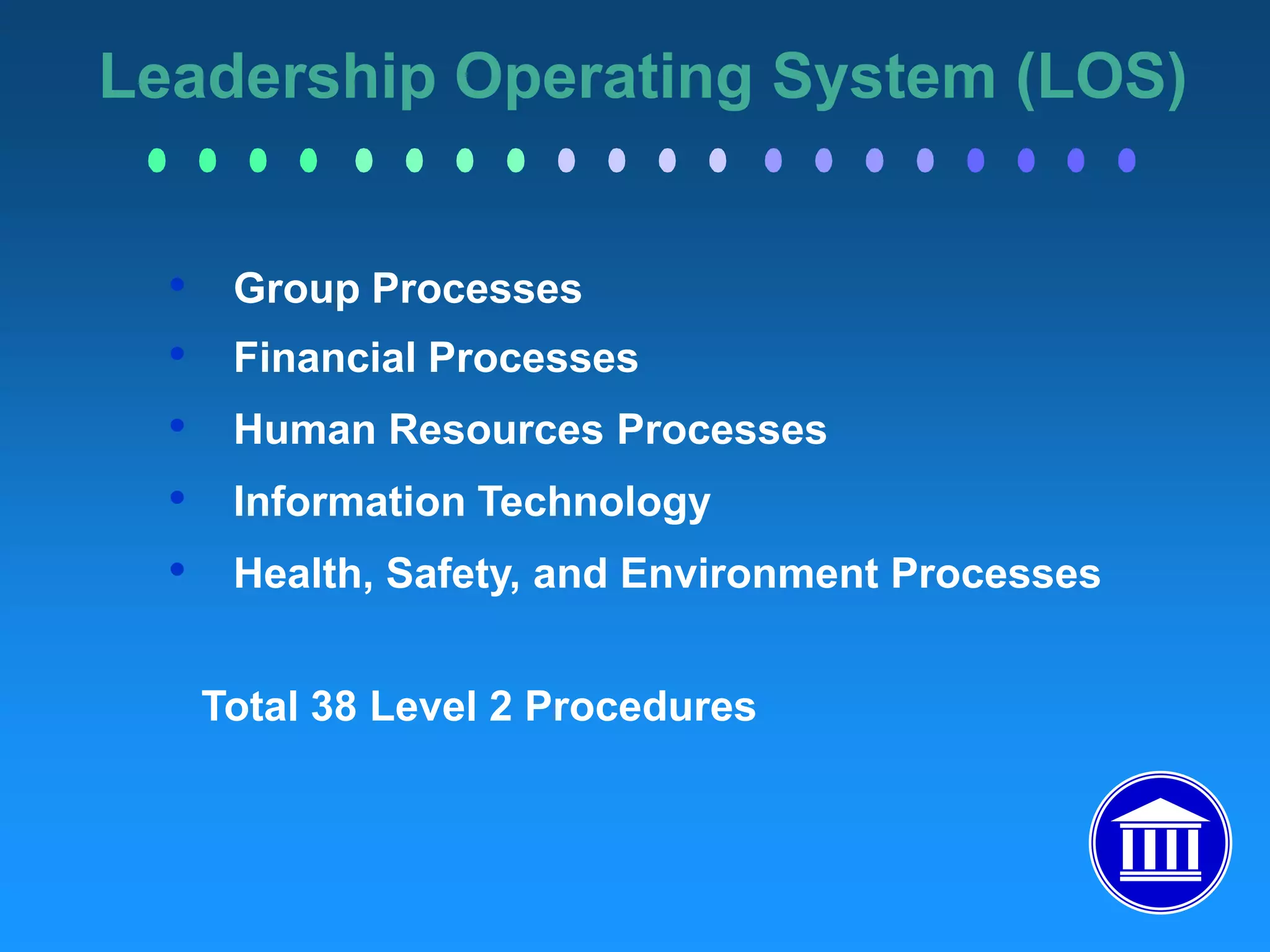

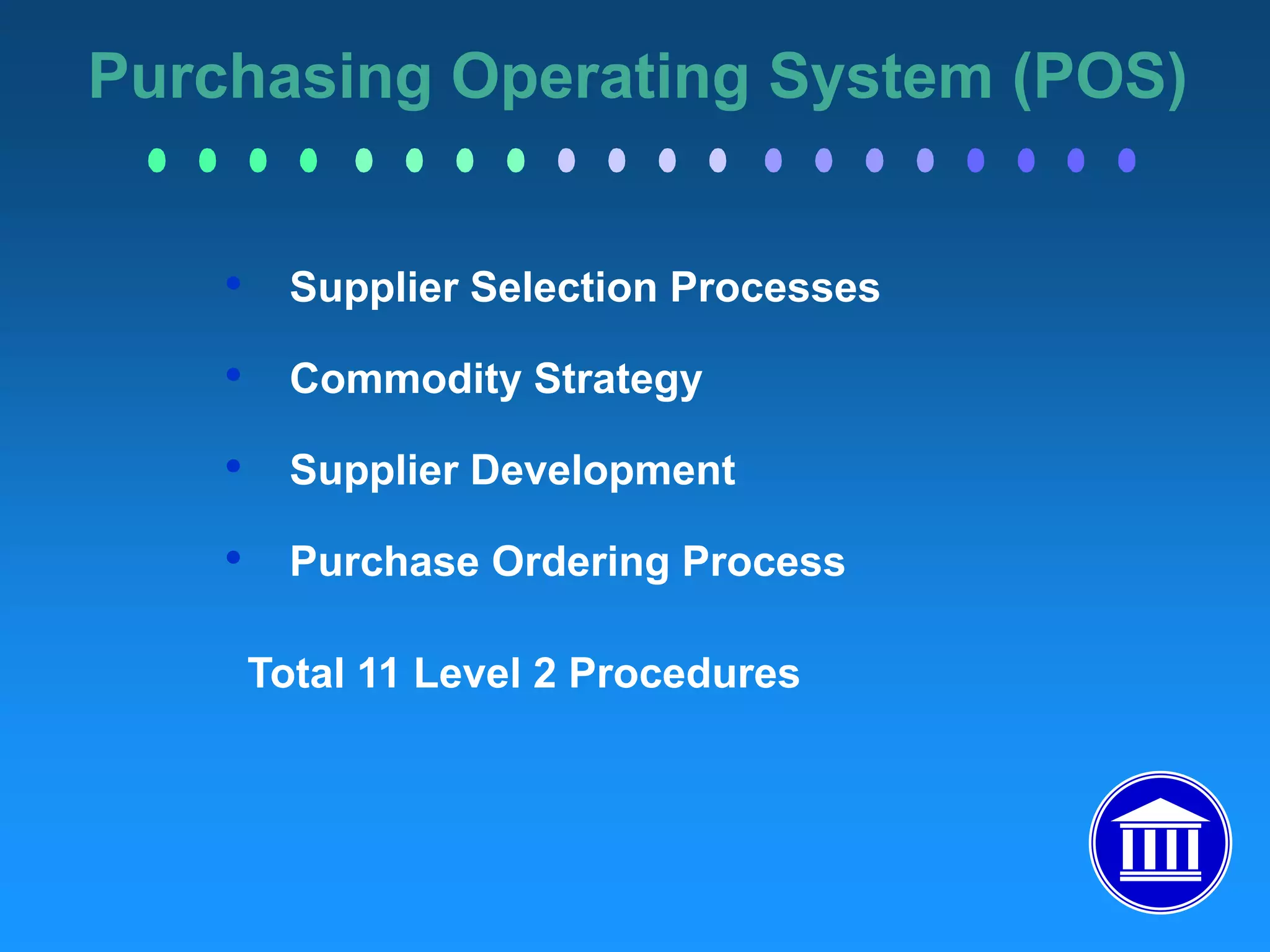

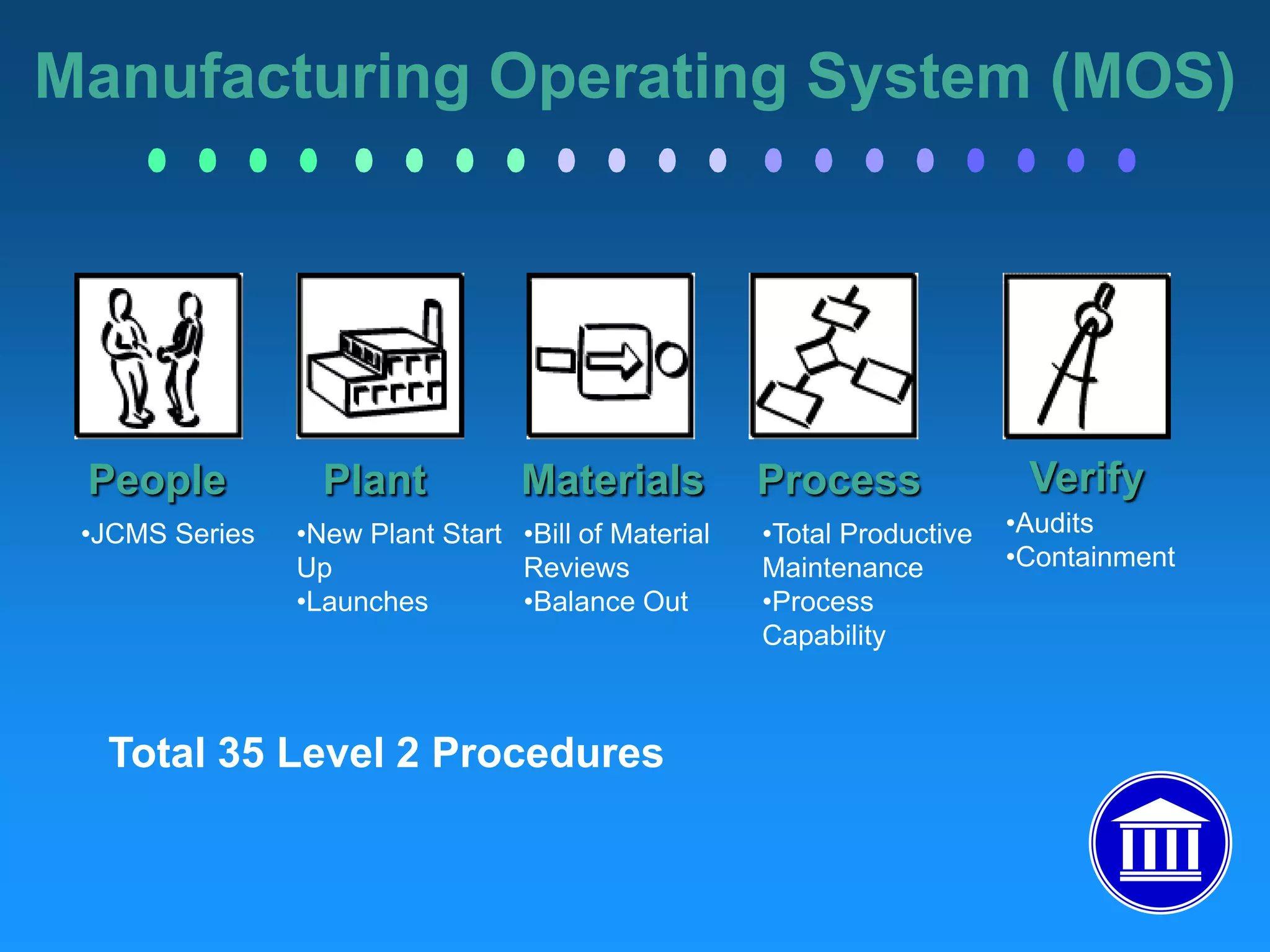

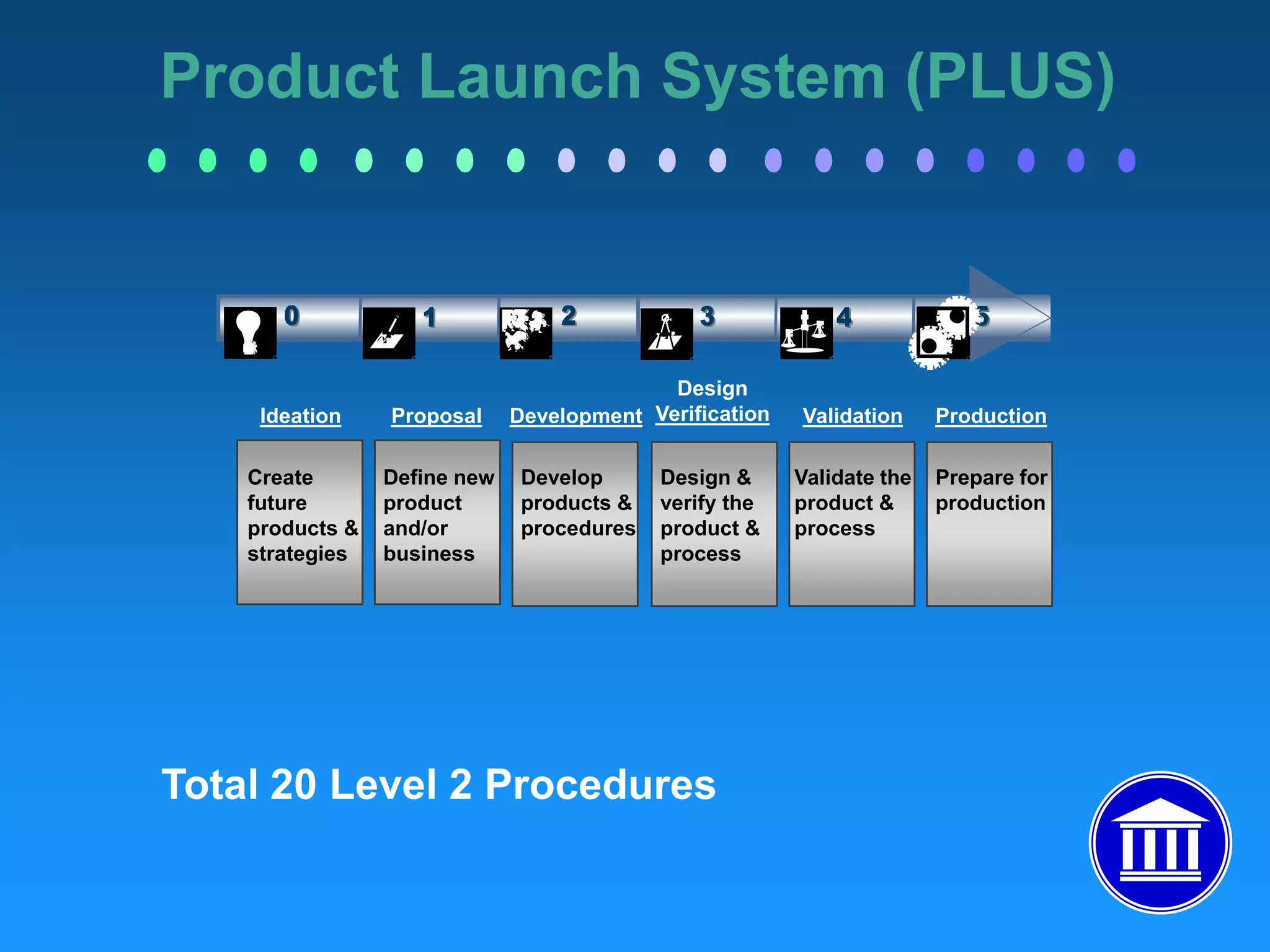

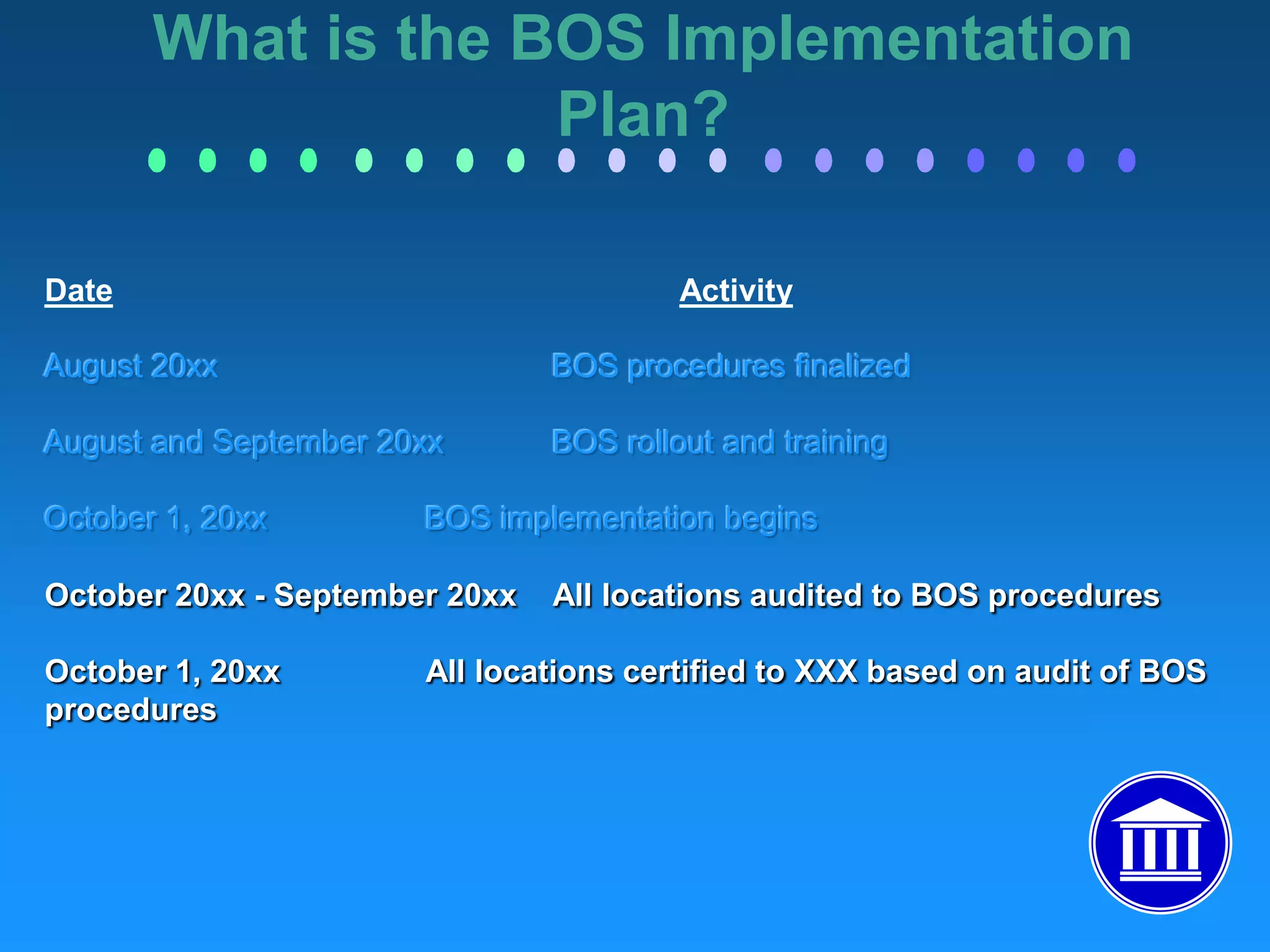

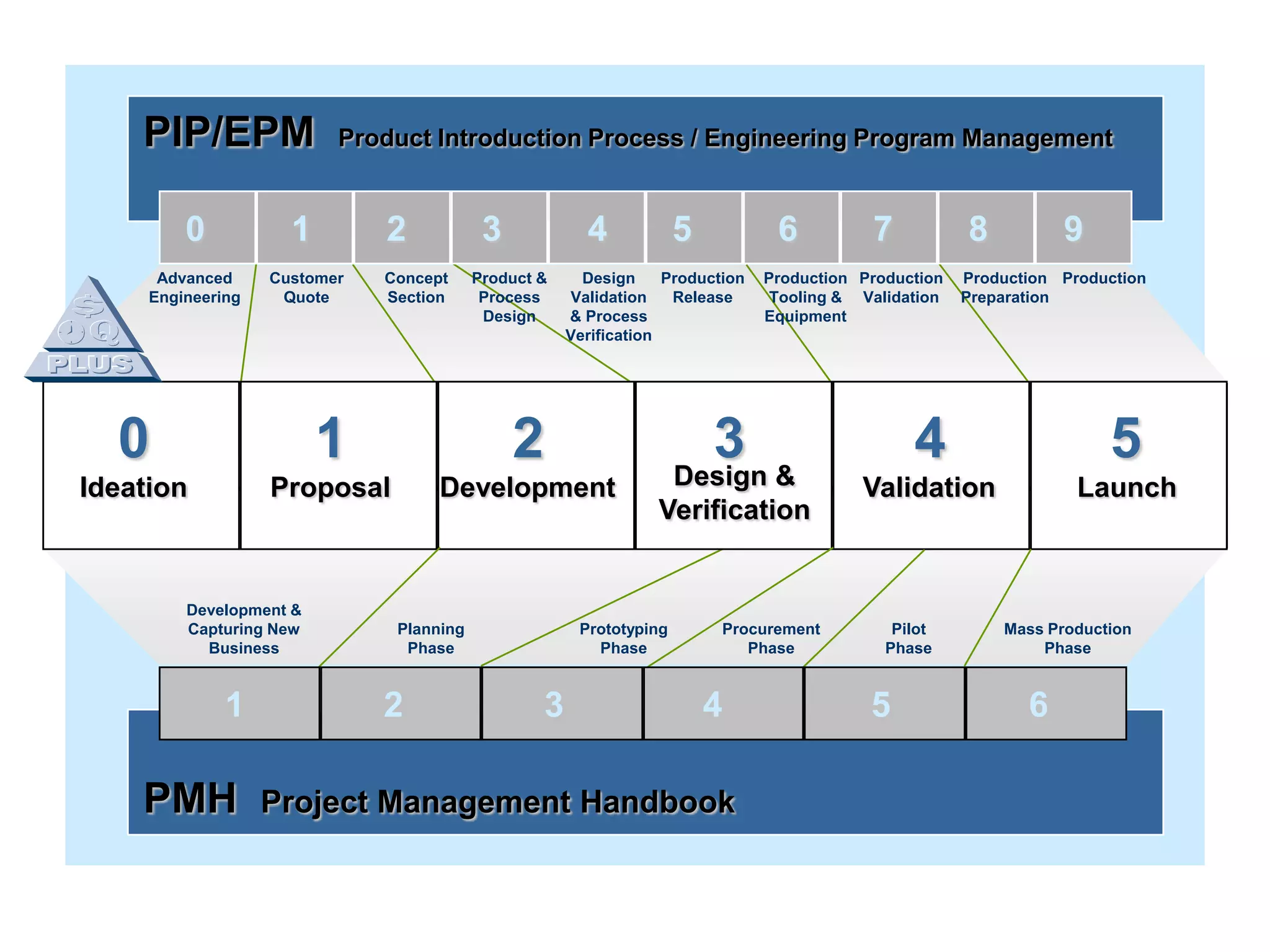

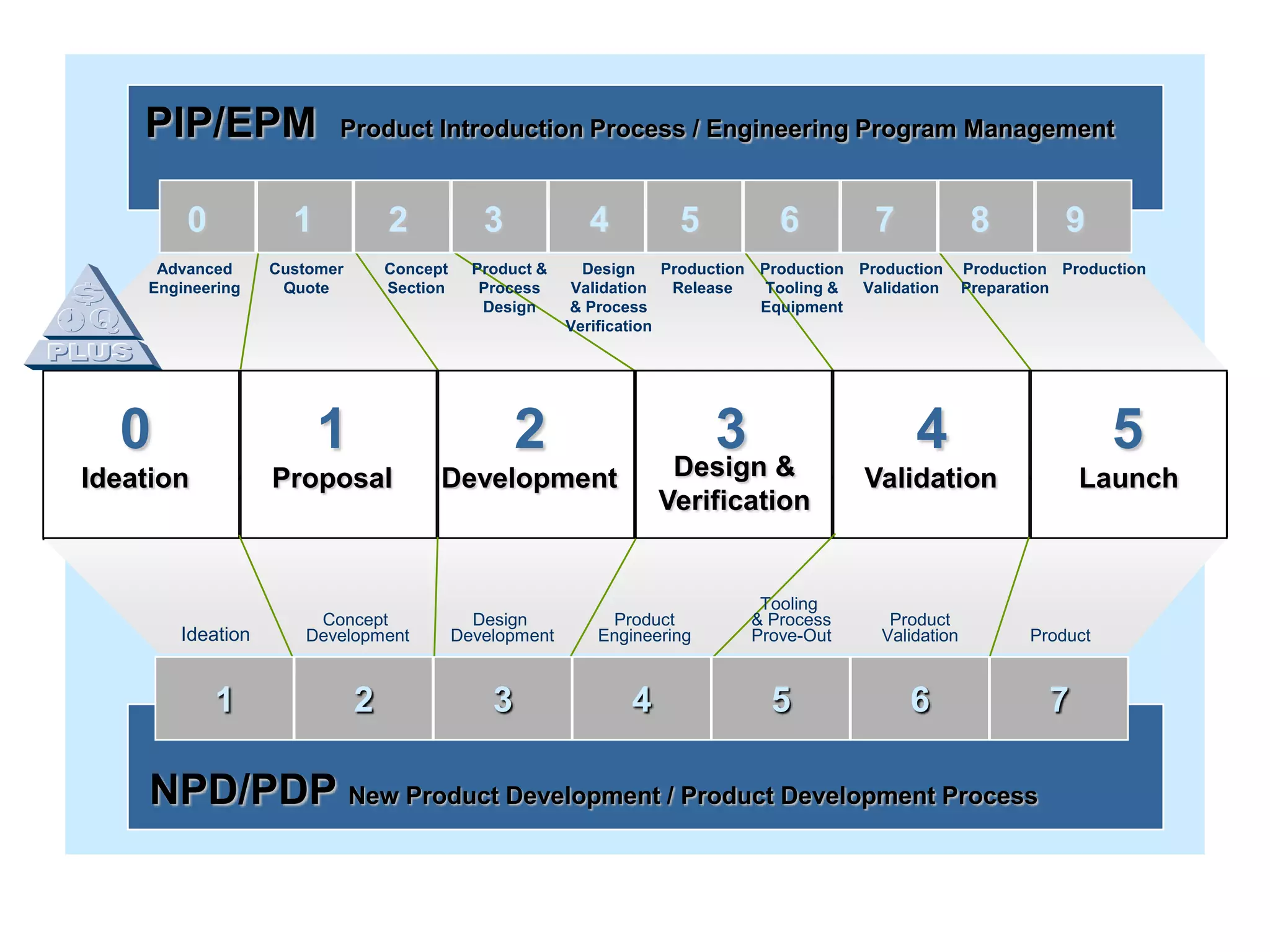

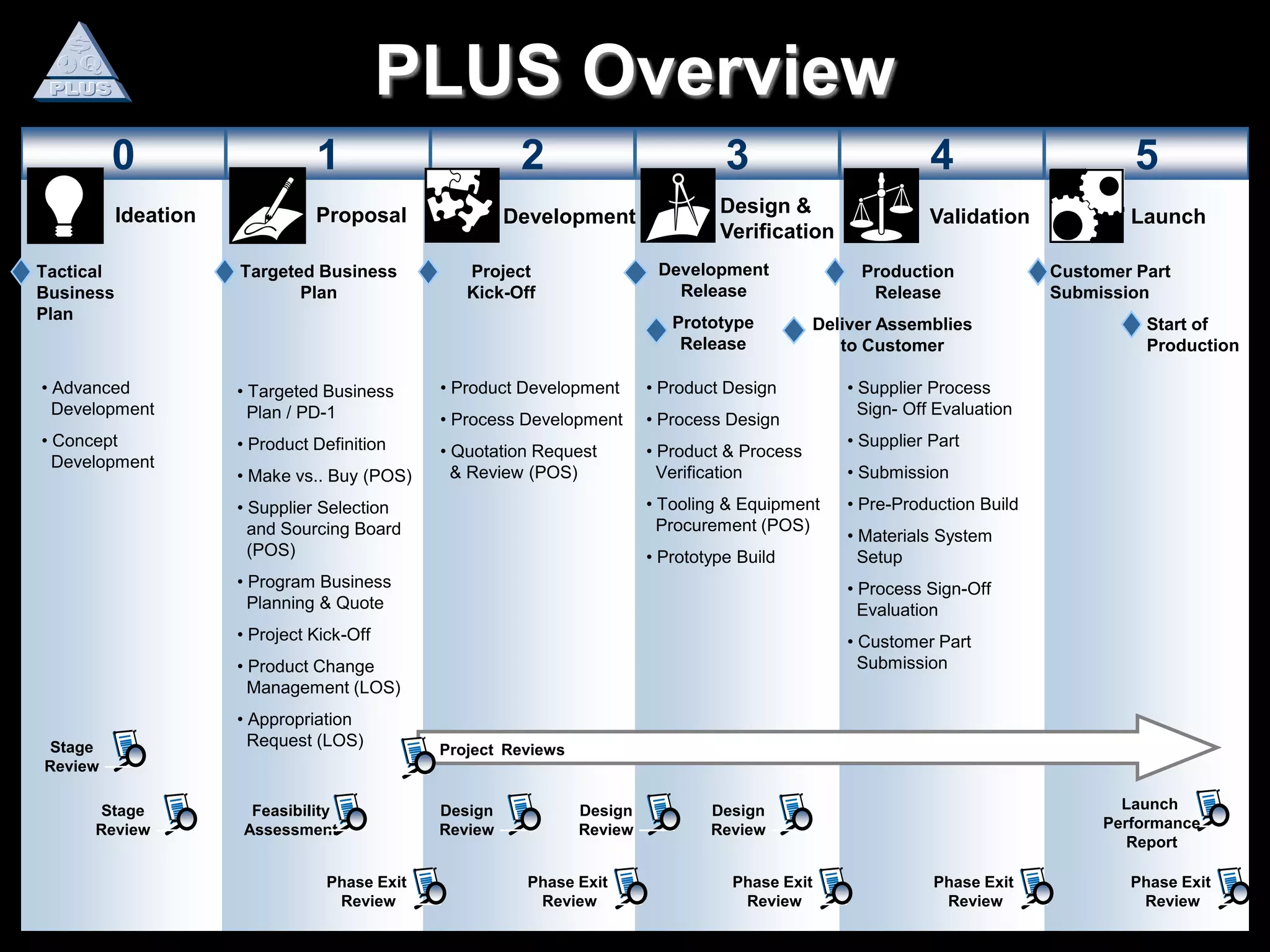

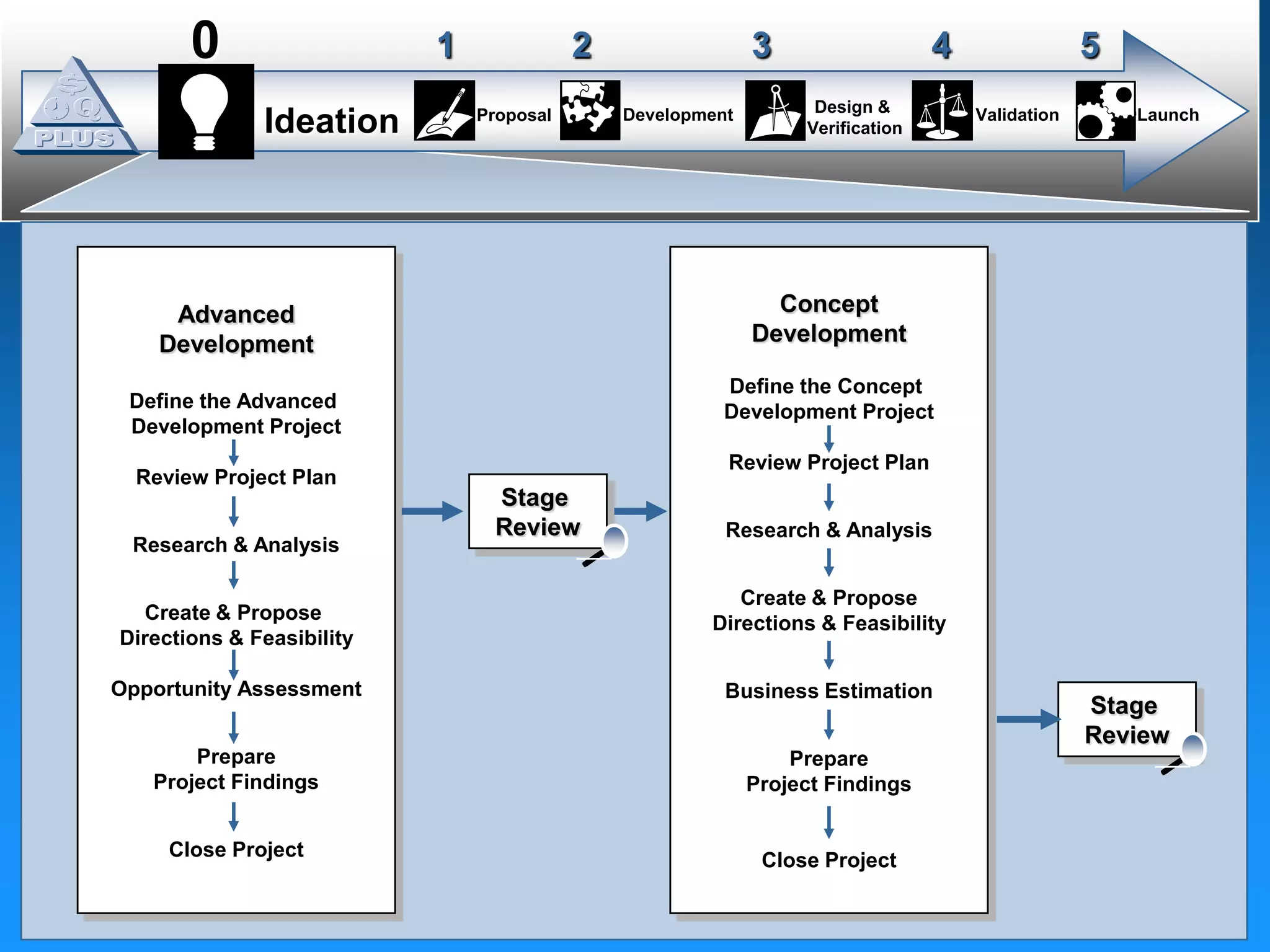

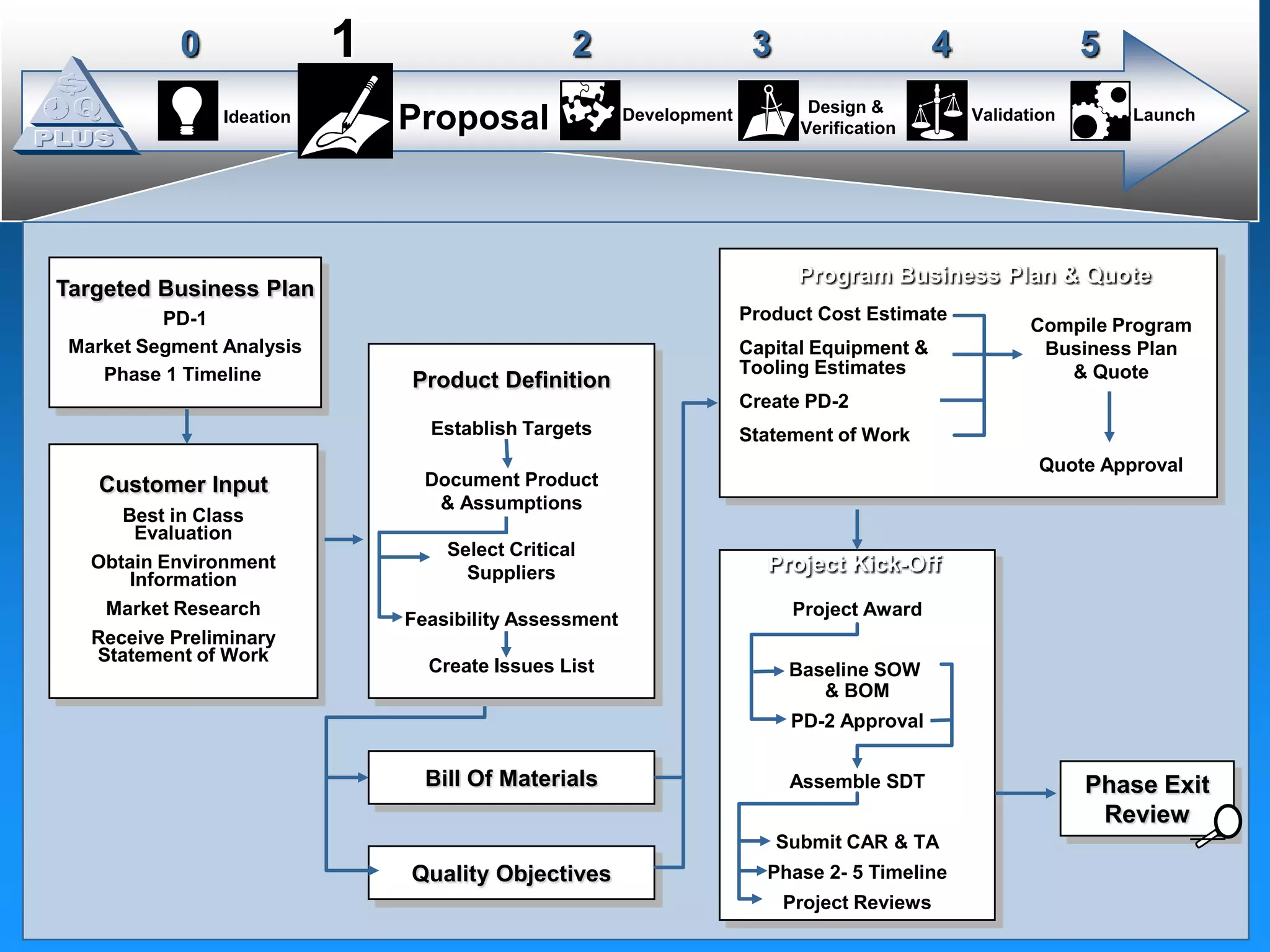

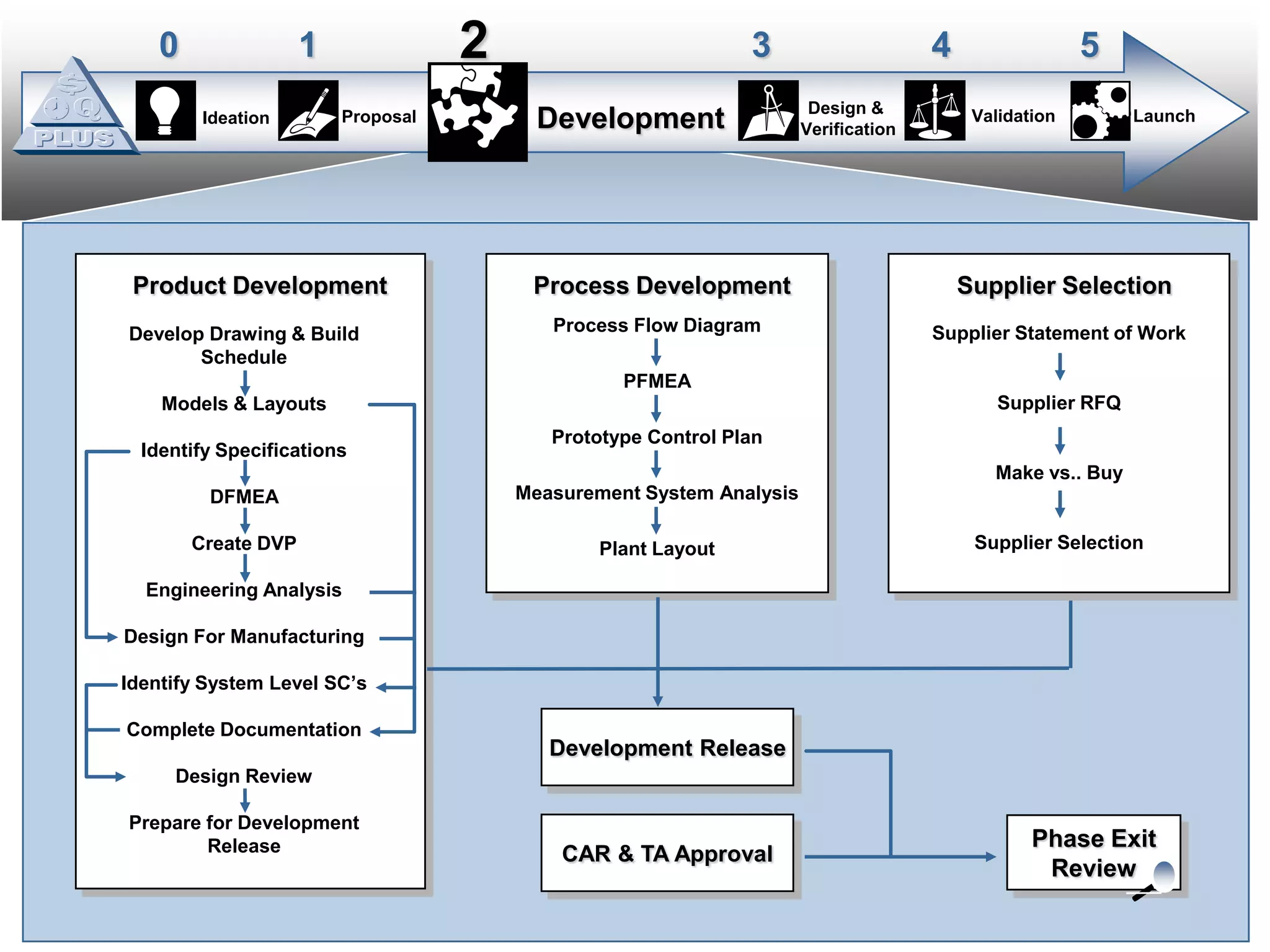

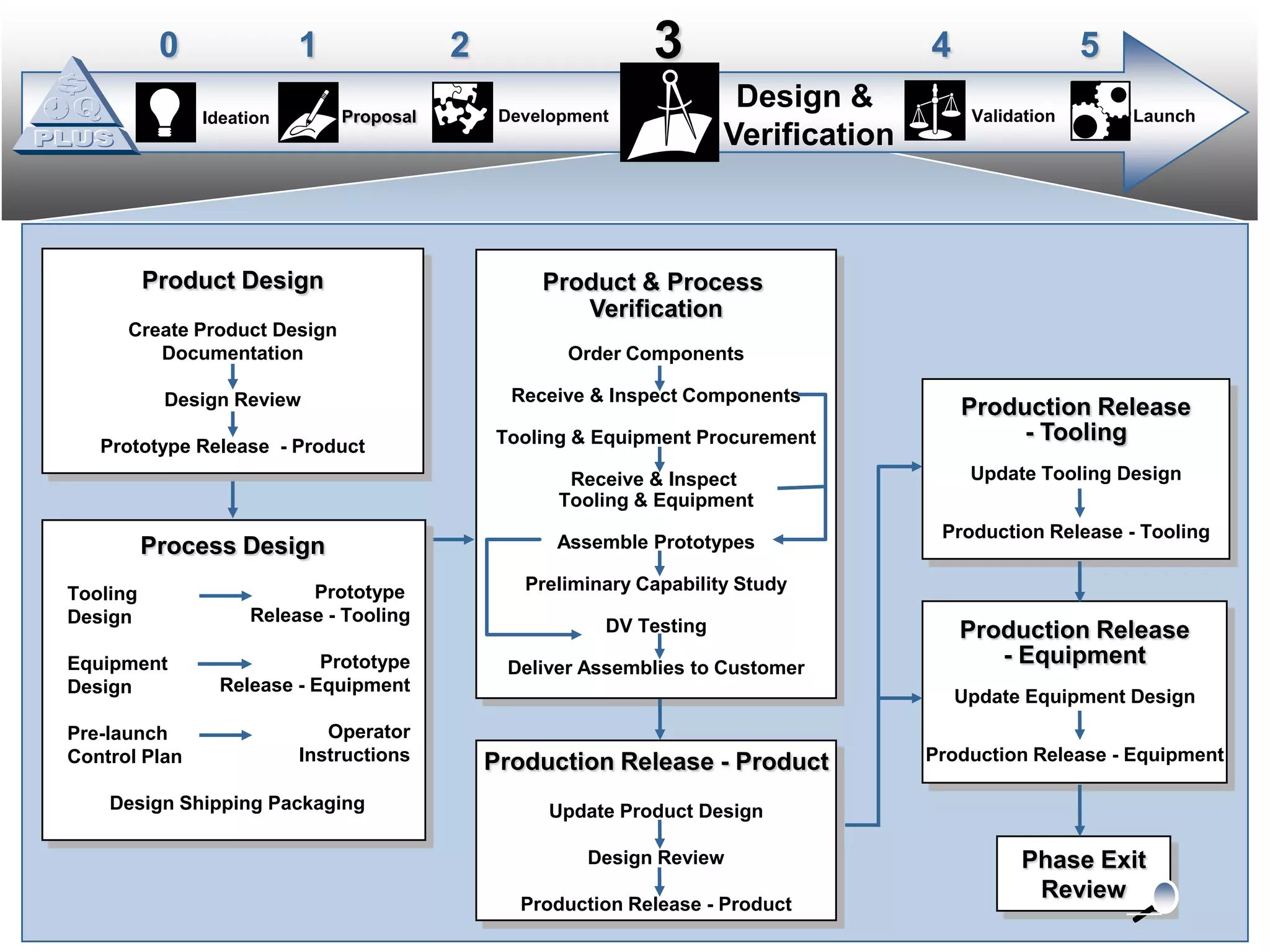

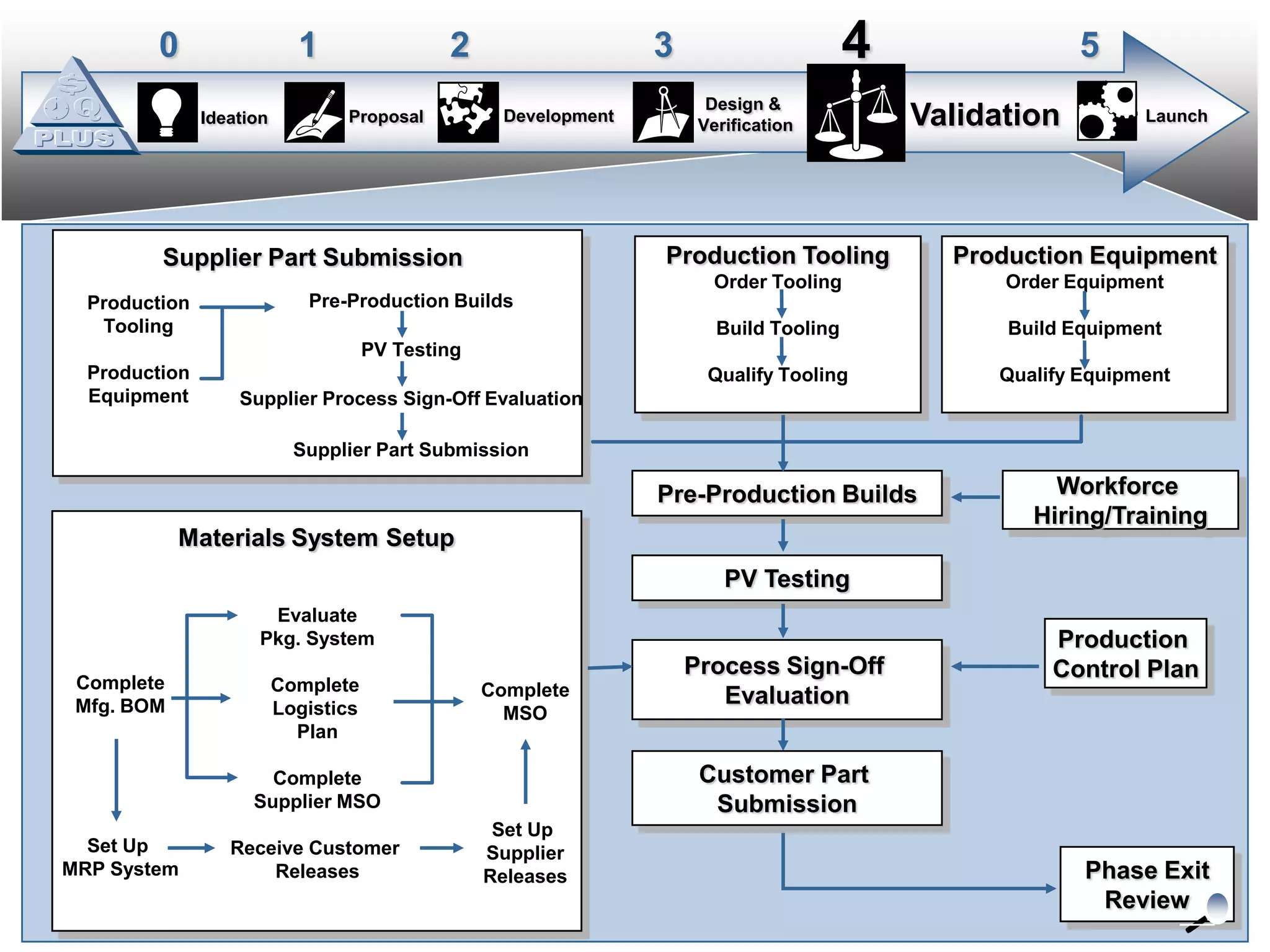

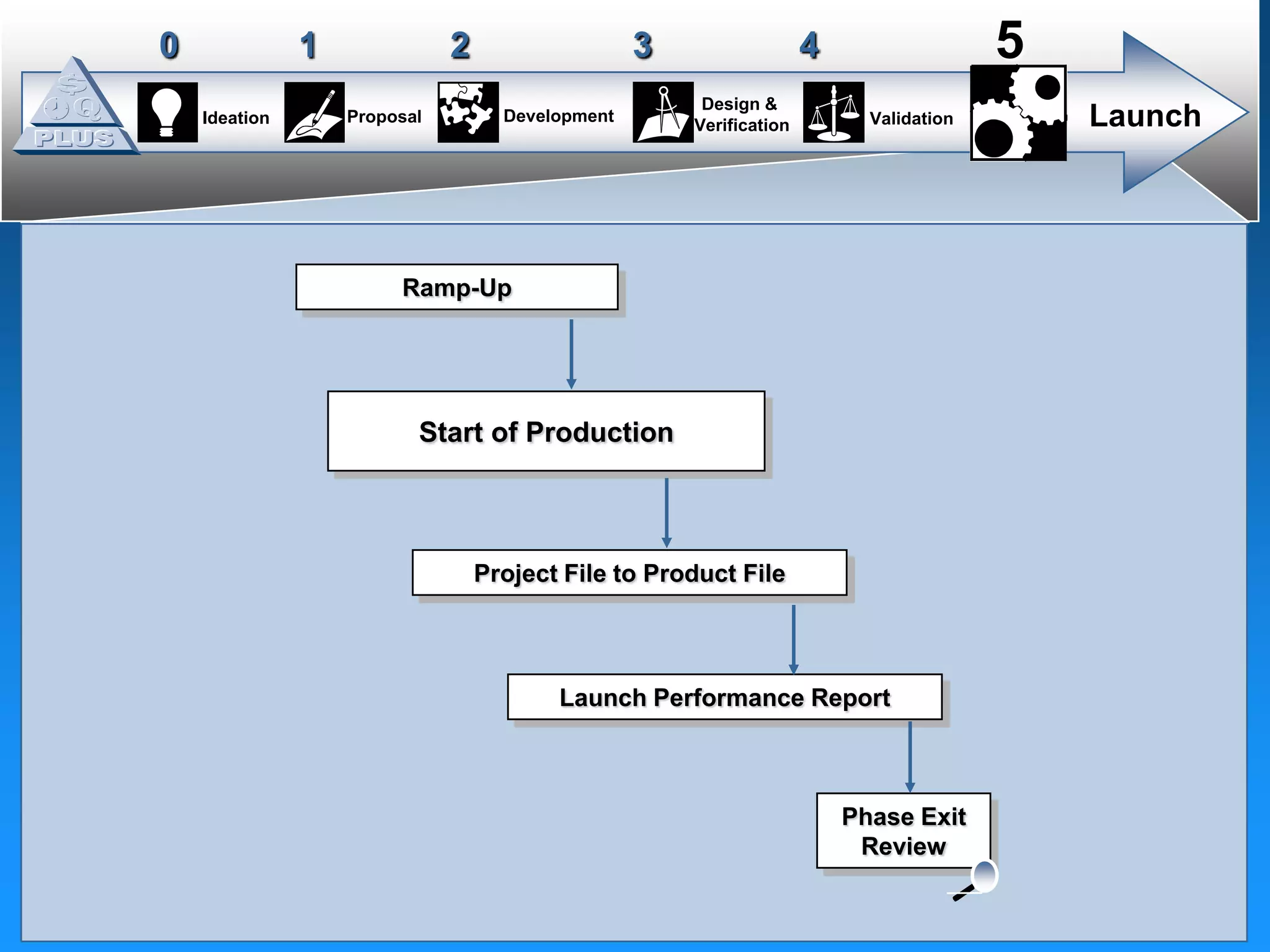

The Business Operating System (BOS) is a collection of global business processes that reflect best practices across the company. BOS replaces all existing operating procedures and includes processes for leadership, purchasing, manufacturing, and product launches. The objective is to create one team, one goal and one operating system. BOS affects all employees worldwide and standardizes functions like quality management, human resources, health and safety, and information technology. A cross-functional team developed BOS to streamline documentation, improve new product development, and meet quality standards globally.