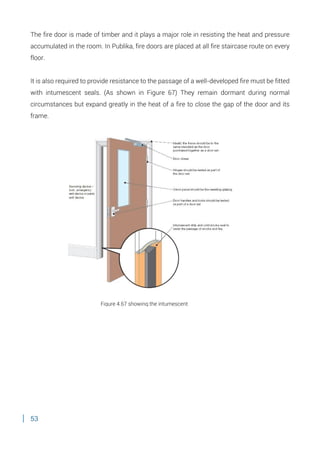

This document provides a detailed overview of the fire protection systems at Publika Solaris Dutamas, a shopping mall and residential development in Kuala Lumpur, Malaysia. It describes both the active and passive fire protection components, including the fire detection system of heat detectors, smoke detectors, and alarm devices. The fire suppression systems such as sprinklers, dry risers, and portable extinguishers are also examined. Compartmentalization techniques like fire doors, smoke curtains and fire escapes are evaluated as part of the passive protection. The document provides information on the relevant codes and regulations in Malaysia and includes diagrams to illustrate the systems.