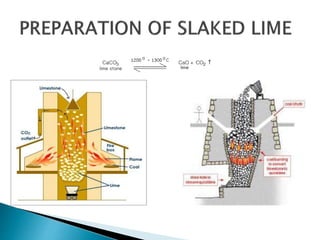

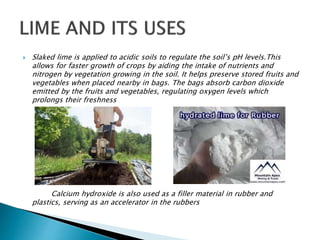

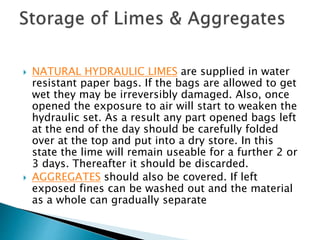

Lime is one of the oldest and most widely used chemicals. It is made by heating limestone to produce quicklime, then hydrating it to produce slaked lime or calcium hydroxide. Slaked lime regulates soil pH and aids plant growth. It also helps preserve fruits and vegetables. Lime mortar, composed of lime, sand, and water, is an ancient type of mortar dating back to ancient Rome and Greece.