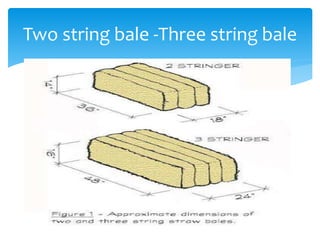

This document discusses straw bale construction. It describes how straw bales are used as structural elements and insulation in buildings. Straw bale construction has been used since ancient times, but was revived in the 1990s. There are two common types of straw bales used - those bound with two strings and those bound with three strings. The document outlines the basic steps to construct a straw bale house, including preparing the foundation, erecting a frame, building the straw bale walls, and plastering. It also discusses common materials, advantages like insulation and cost effectiveness, disadvantages like moisture issues, and precautions needed during construction.