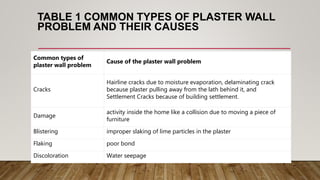

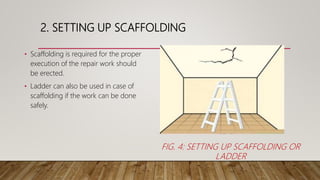

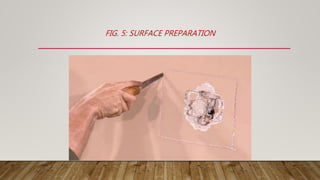

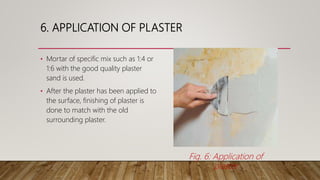

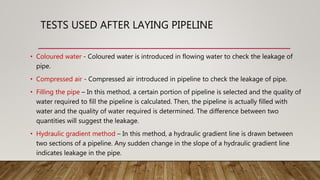

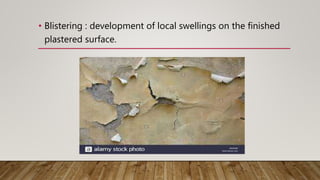

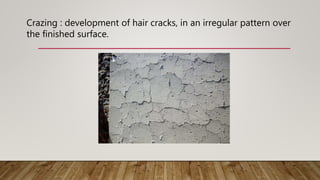

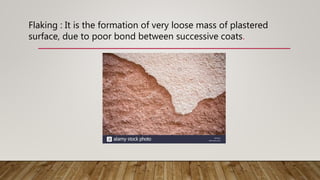

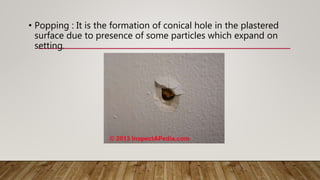

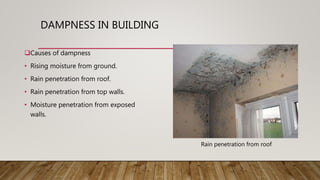

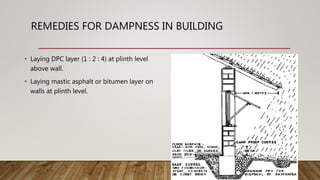

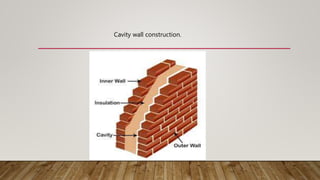

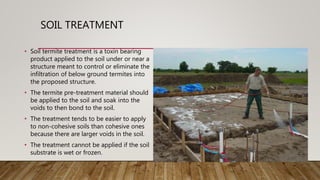

The document discusses the importance of building maintenance, outlining causes of structural failure, types of maintenance works, and specific repair techniques. It covers aspects such as preventative measures, inspection requirements, and the conditions affecting durability, as well as detailed procedures for common repairs like plastering and replacing door frames. Additionally, it addresses common defects in buildings and remedies for issues such as dampness and termite attacks.