Embed presentation

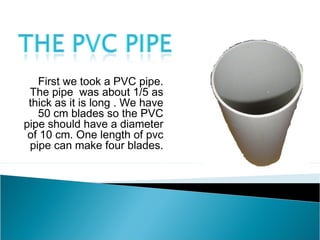

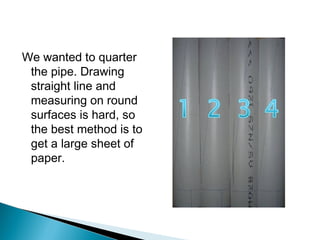

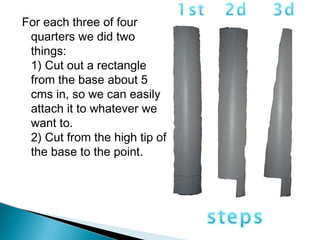

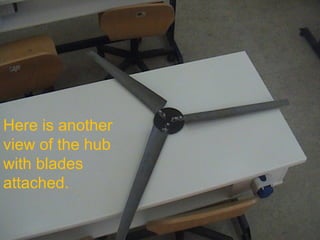

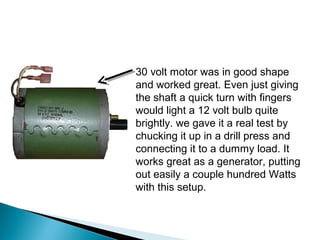

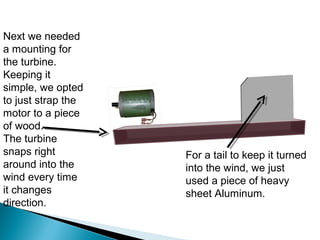

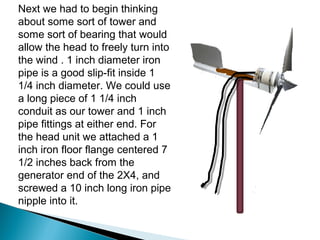

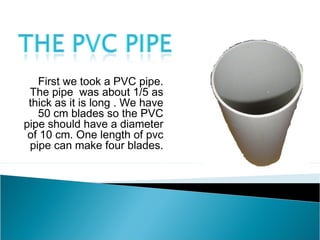

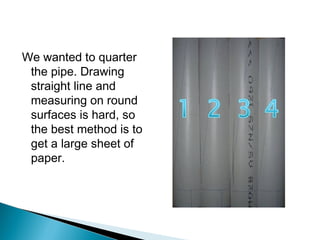

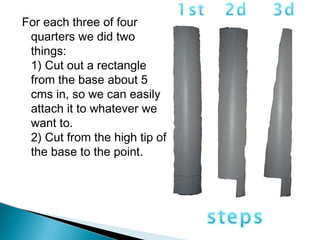

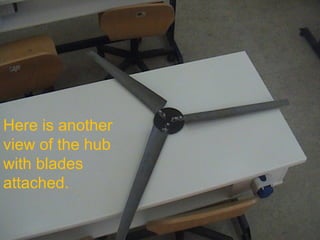

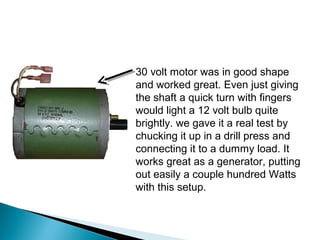

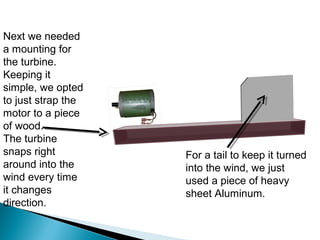

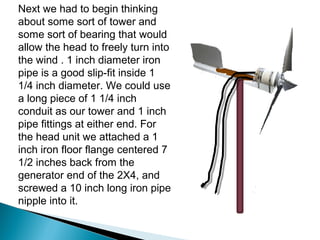

The document describes the process of making wind turbine blades out of PVC pipe. It explains how to quarter the pipe into four equal sections to make blades. It also discusses attaching the blades to a hub and mounting a 30V motor that acts as a generator when spun by the wind. Finally, it mentions using a wooden mount, aluminum tail, and iron pipe tower to support the turbine head unit above the ground.