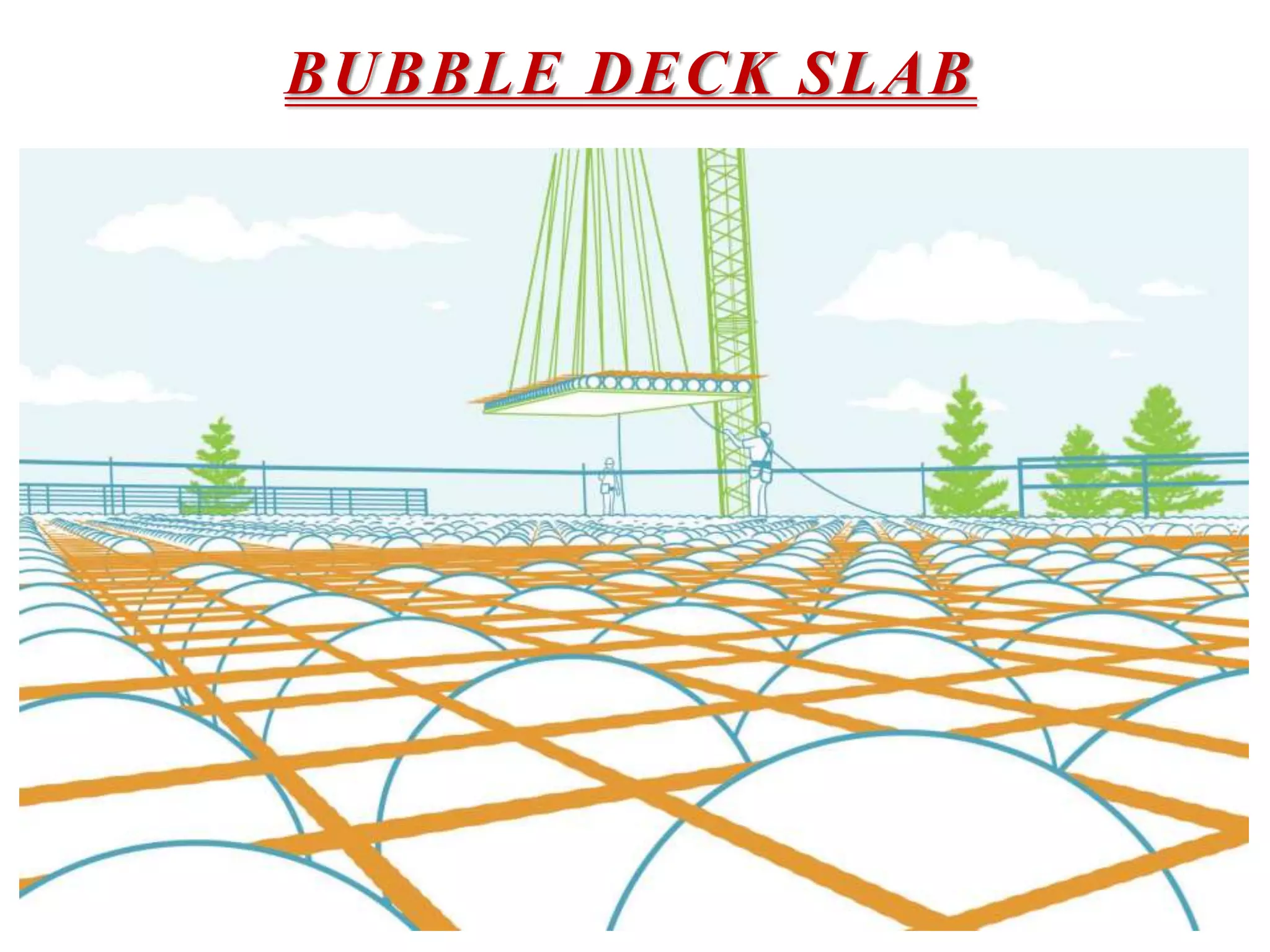

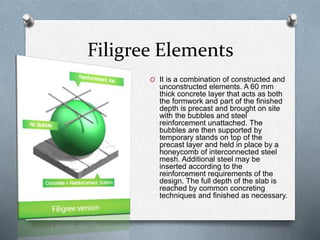

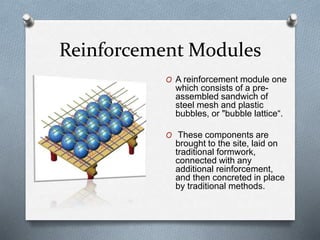

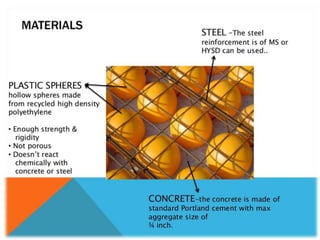

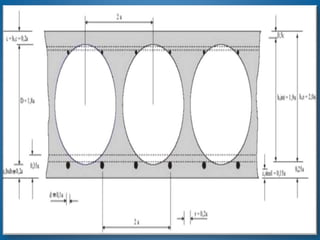

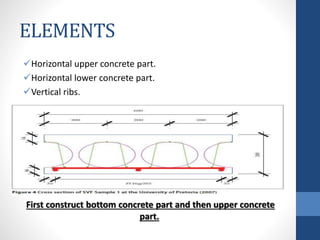

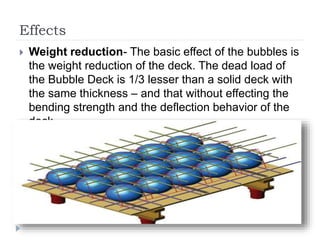

The document discusses bubble deck slabs, which are hollow concrete slabs that use plastic spheres to replace ineffective concrete. There are three main types - filigree elements, reinforcement modules, and finished planks. Bubble deck slabs are lighter than traditional slabs, stronger, allow for larger spans, and use less material. They also provide benefits like reduced construction time and costs as well as being more environmentally friendly through lower CO2 emissions.