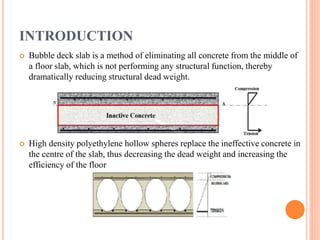

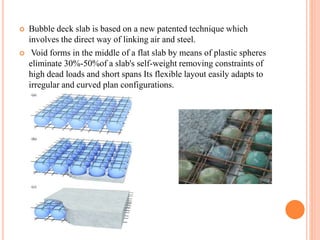

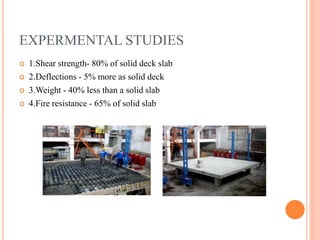

This document presents information on bubble deck slabs. It discusses that bubble deck slabs reduce the weight of concrete floor slabs by replacing concrete in the middle with hollow plastic spheres. This reduces the slab weight by 30-50% while maintaining similar structural properties. Experimental studies found bubble deck slabs have 80% of the shear strength and are 5% more flexible than solid slabs, but are 40% lighter. Bubble deck slabs could be used for constructing tall buildings, auditoriums, and parking structures due to their lighter weight and increased spans.