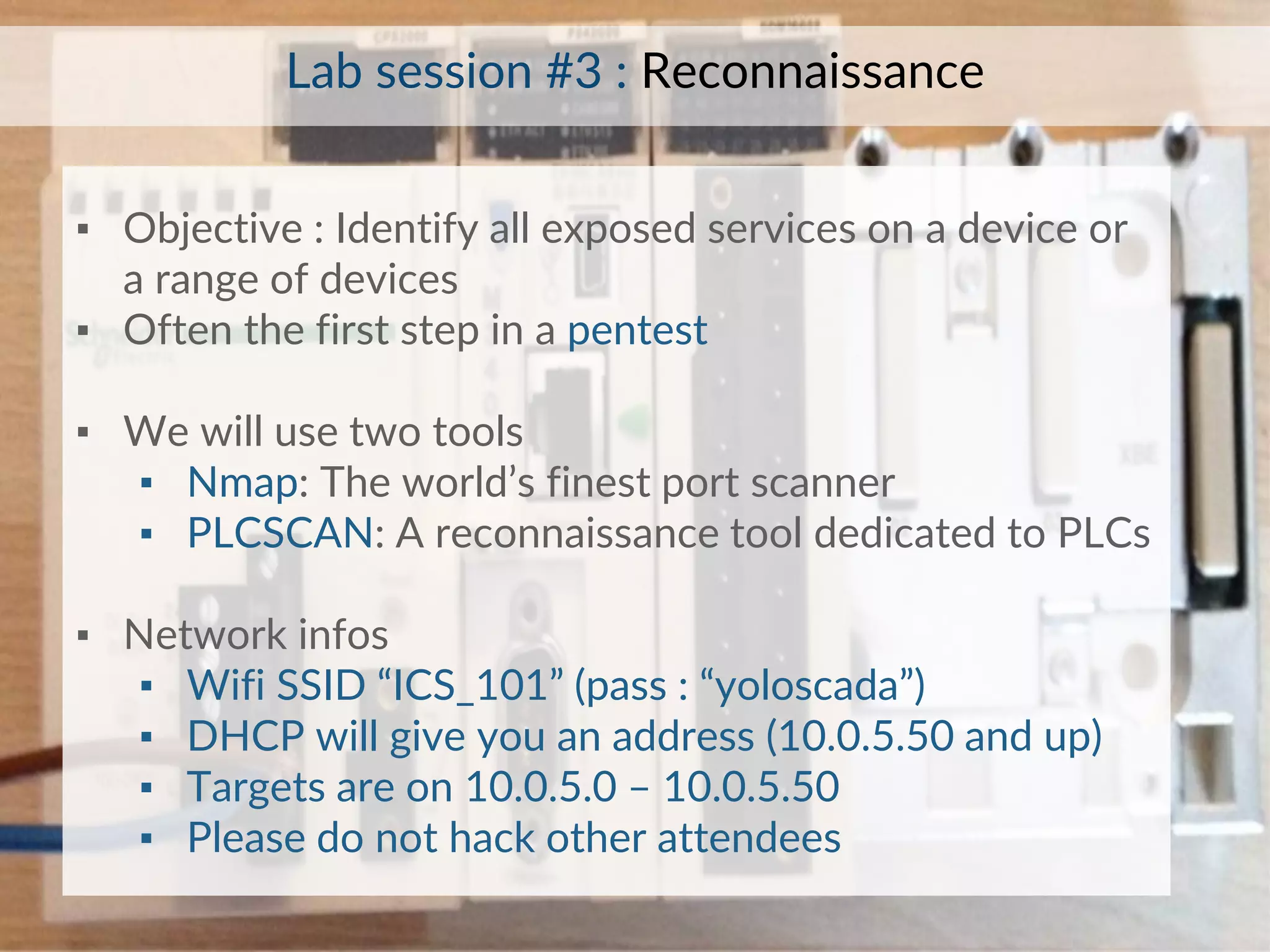

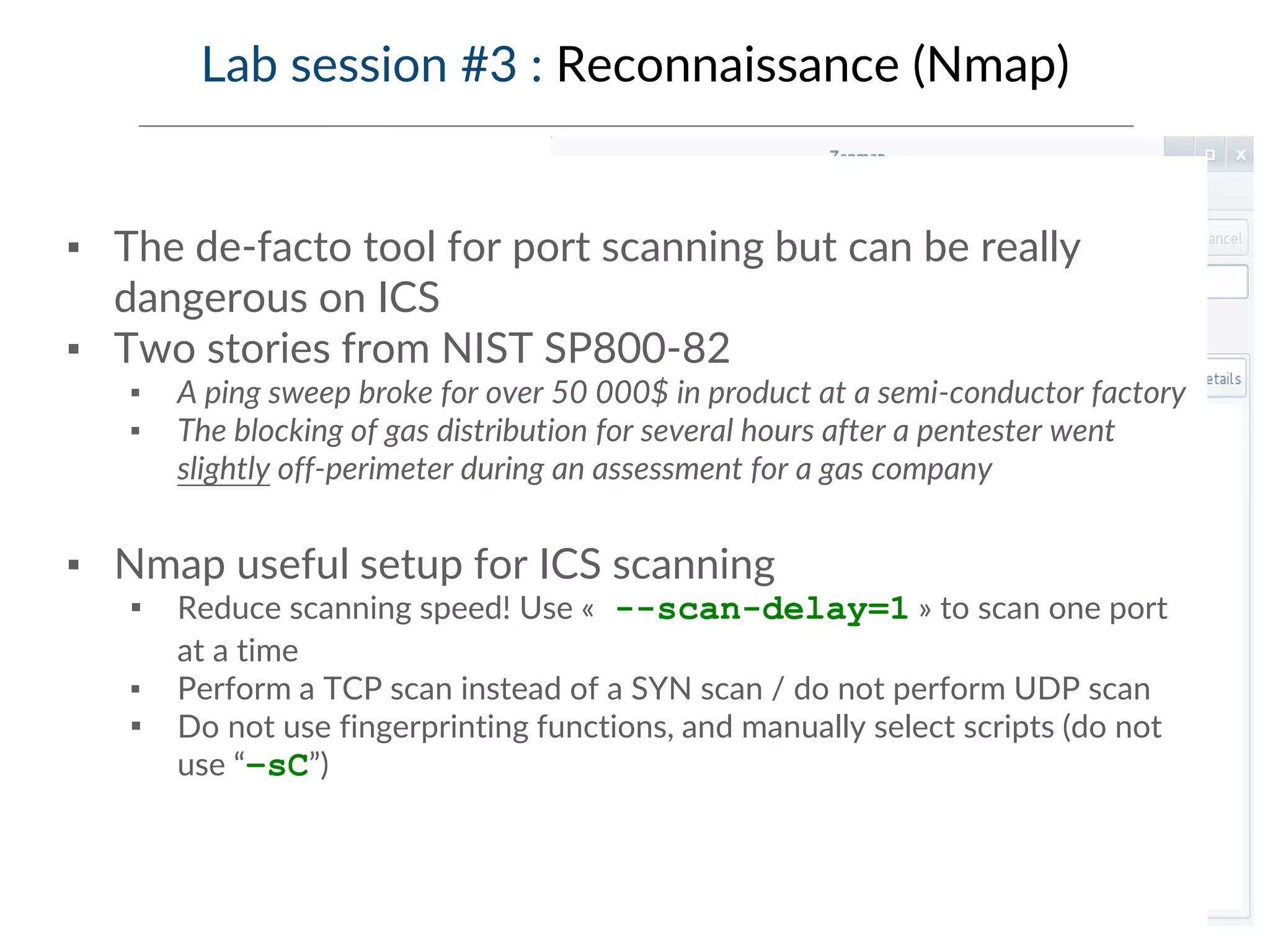

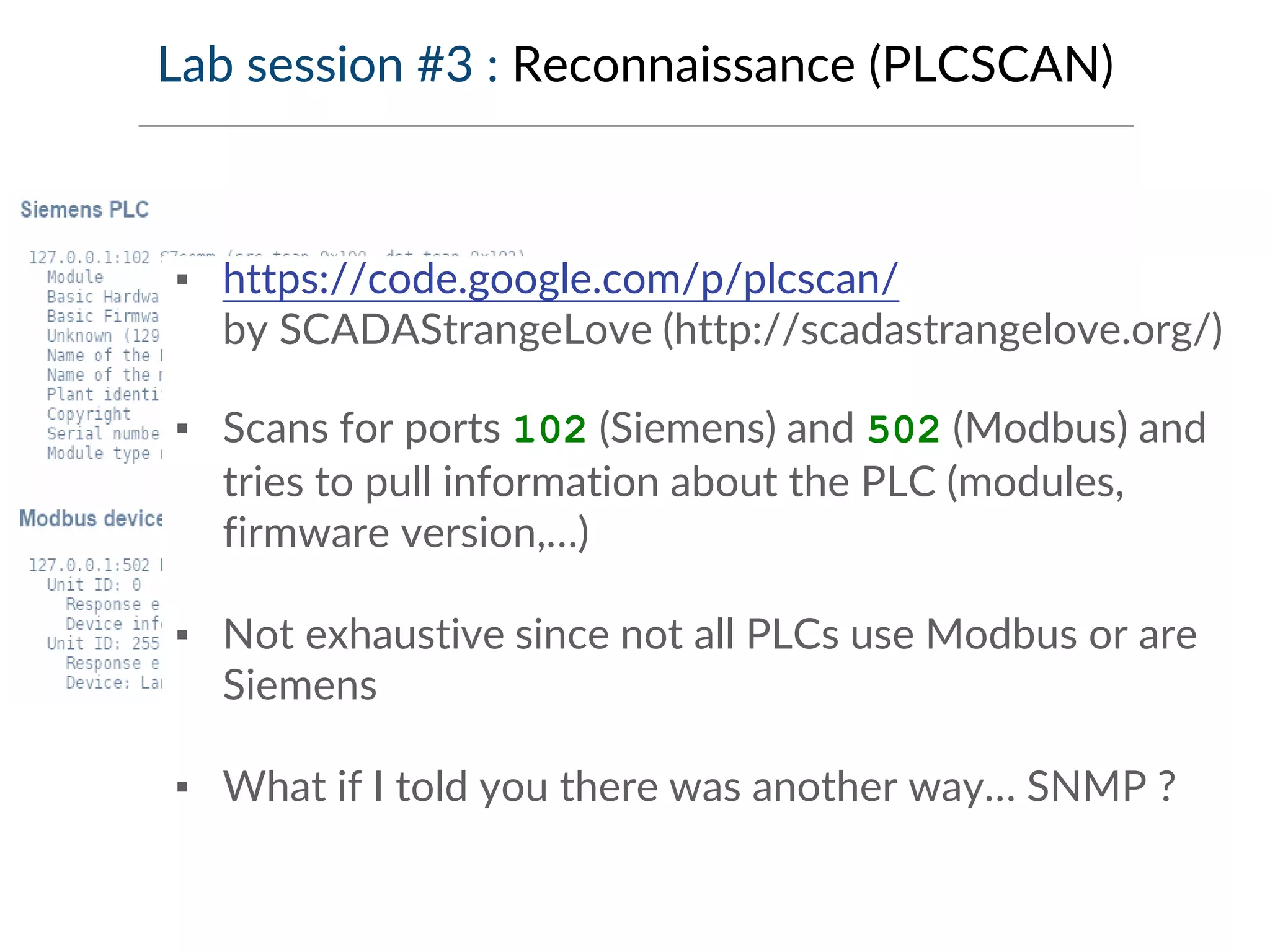

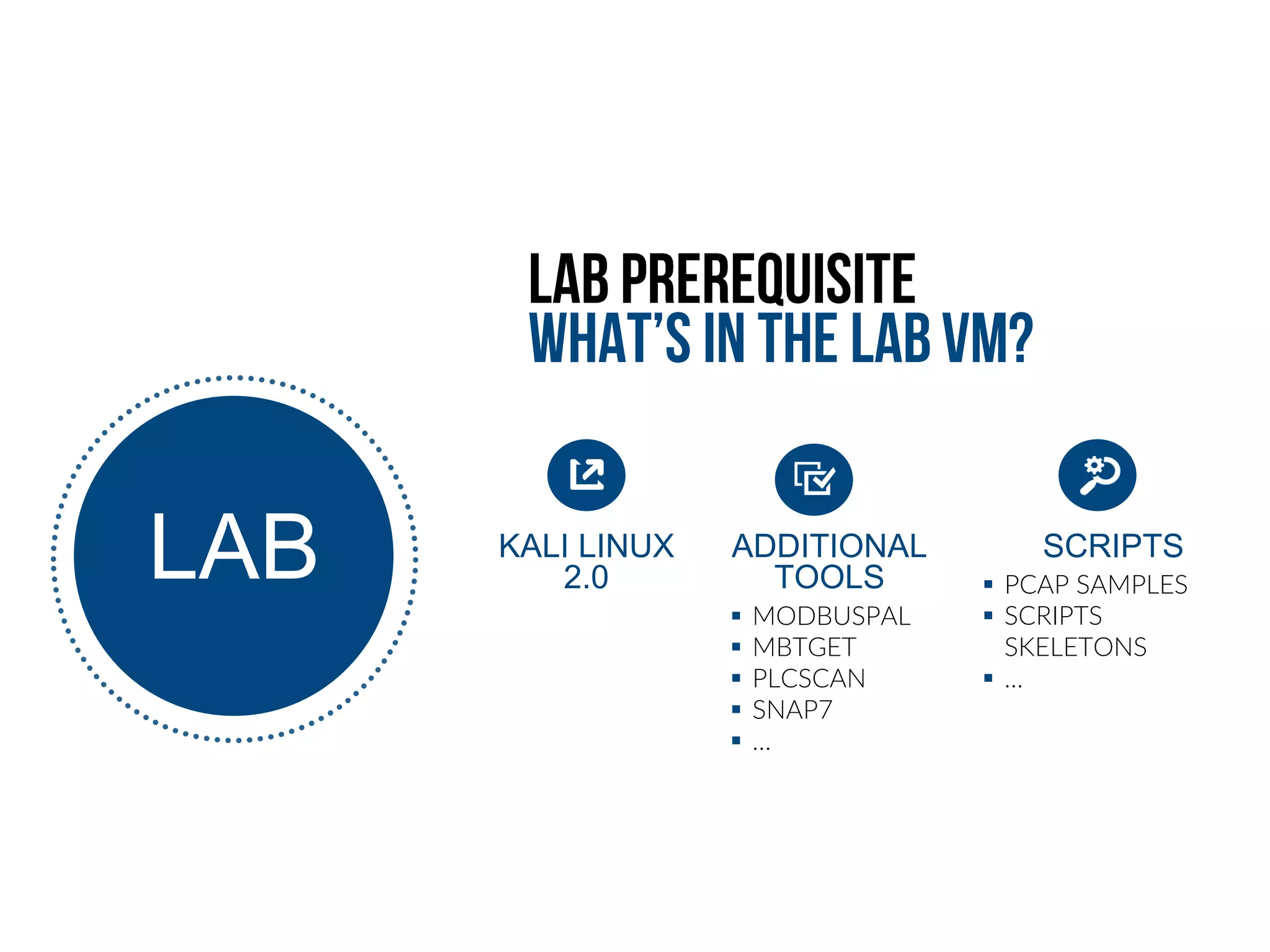

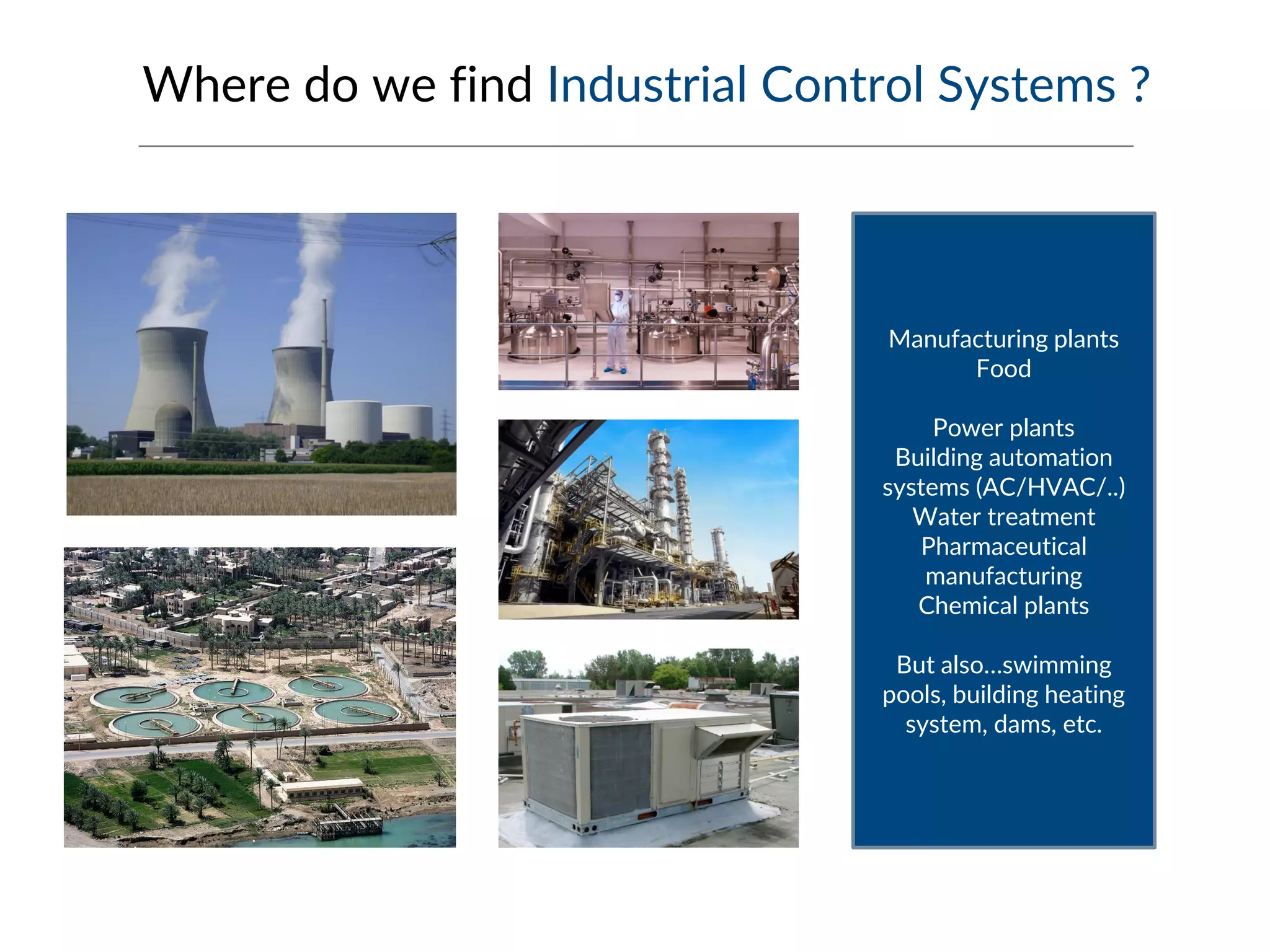

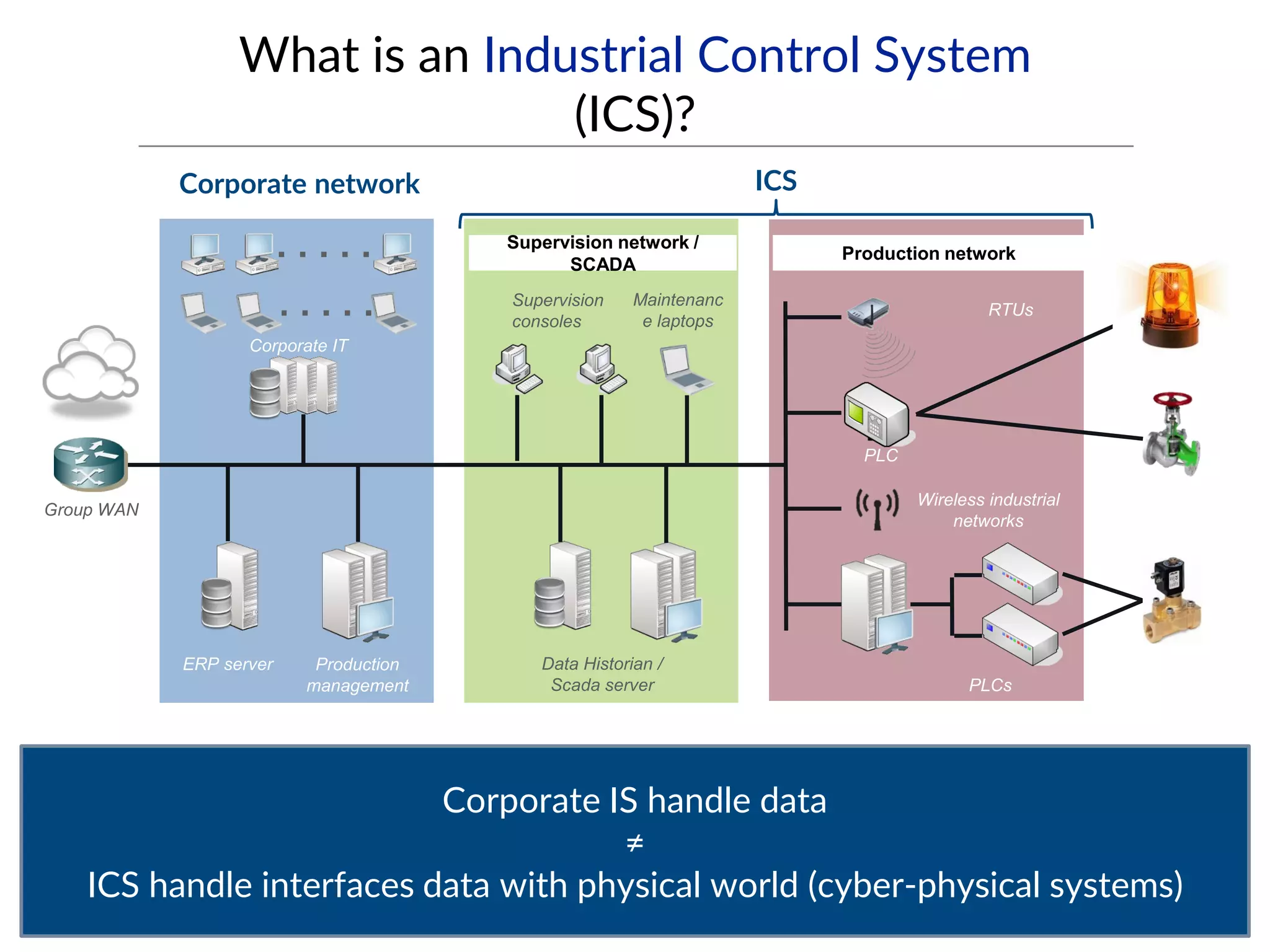

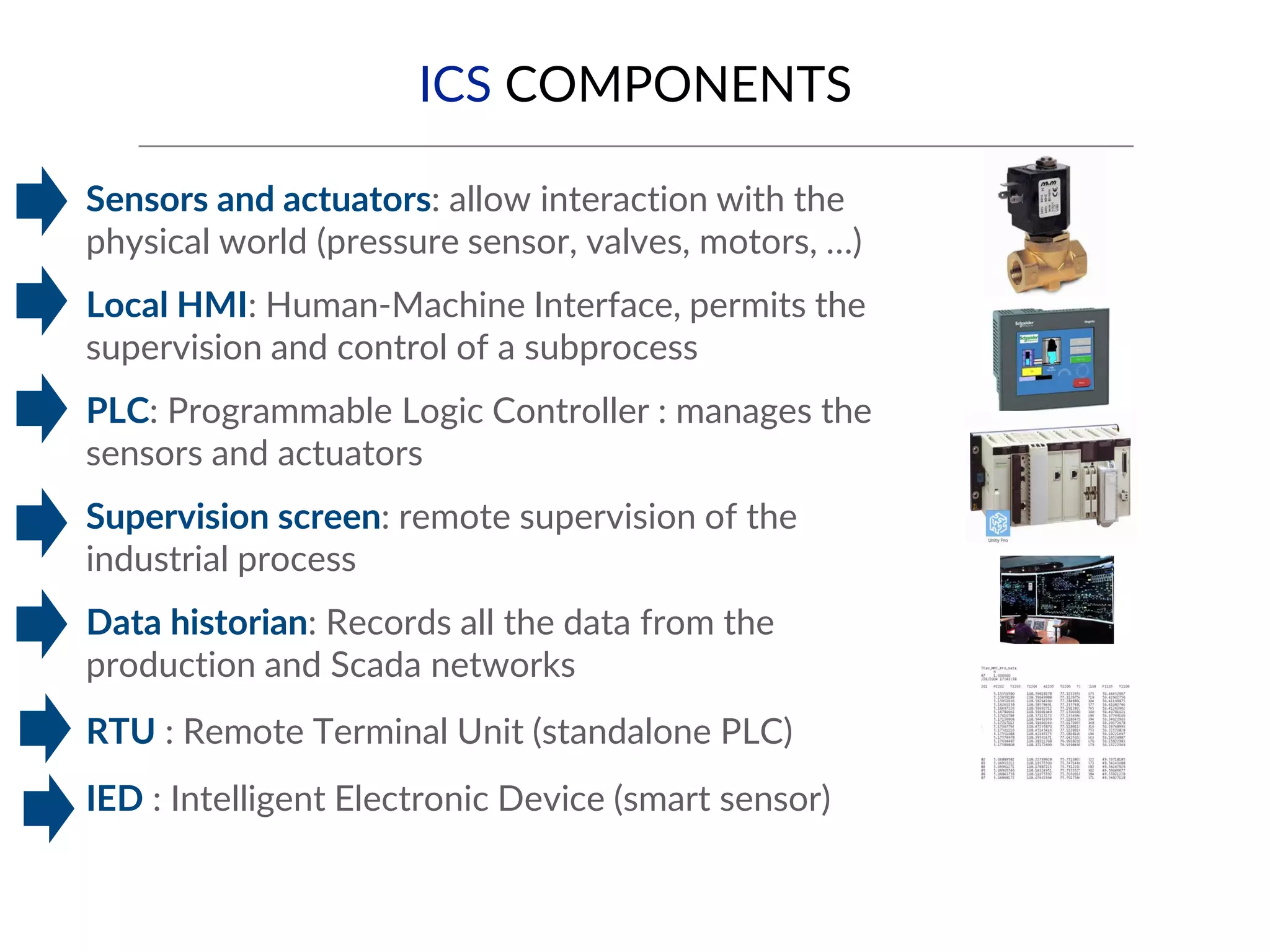

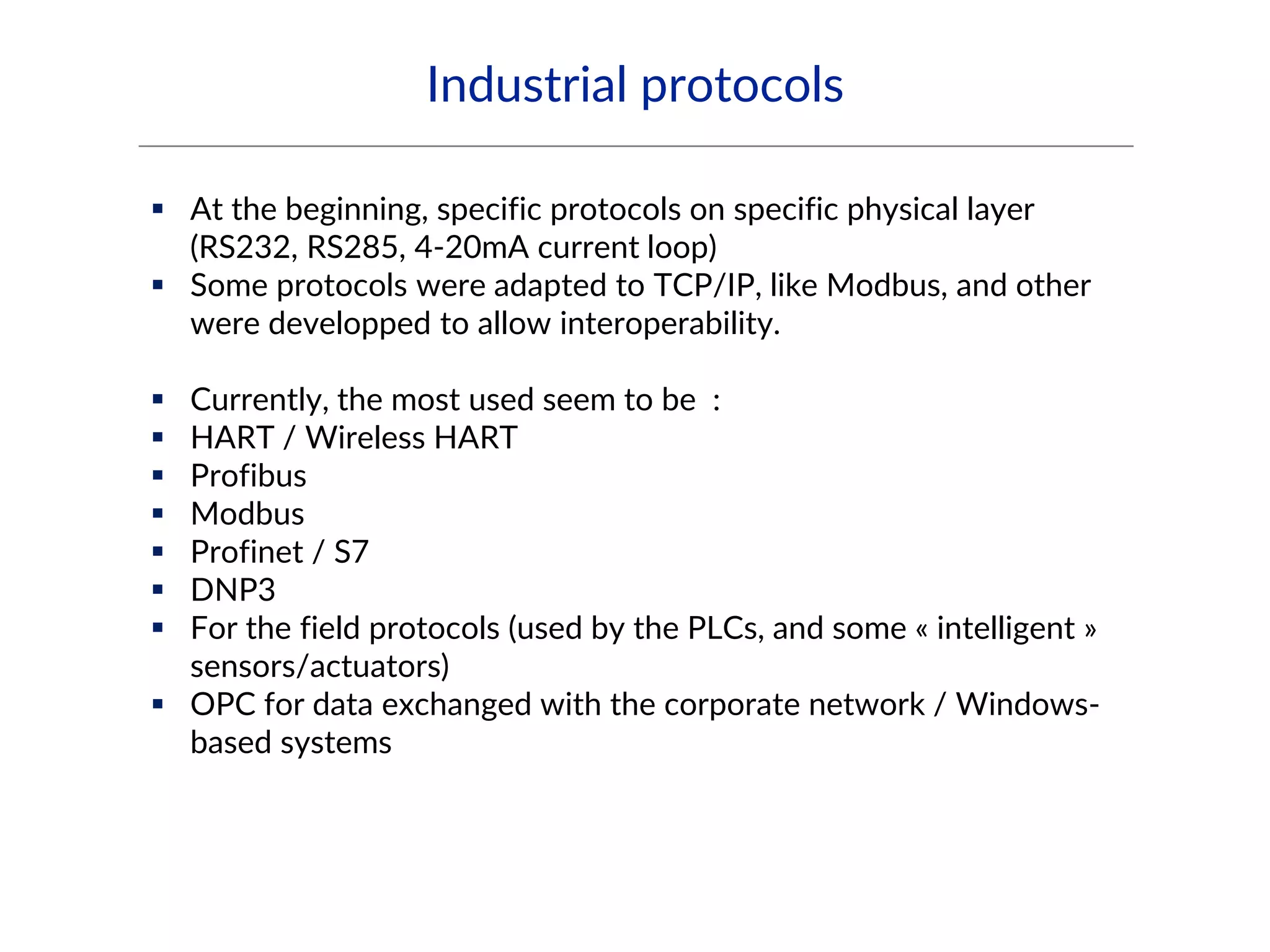

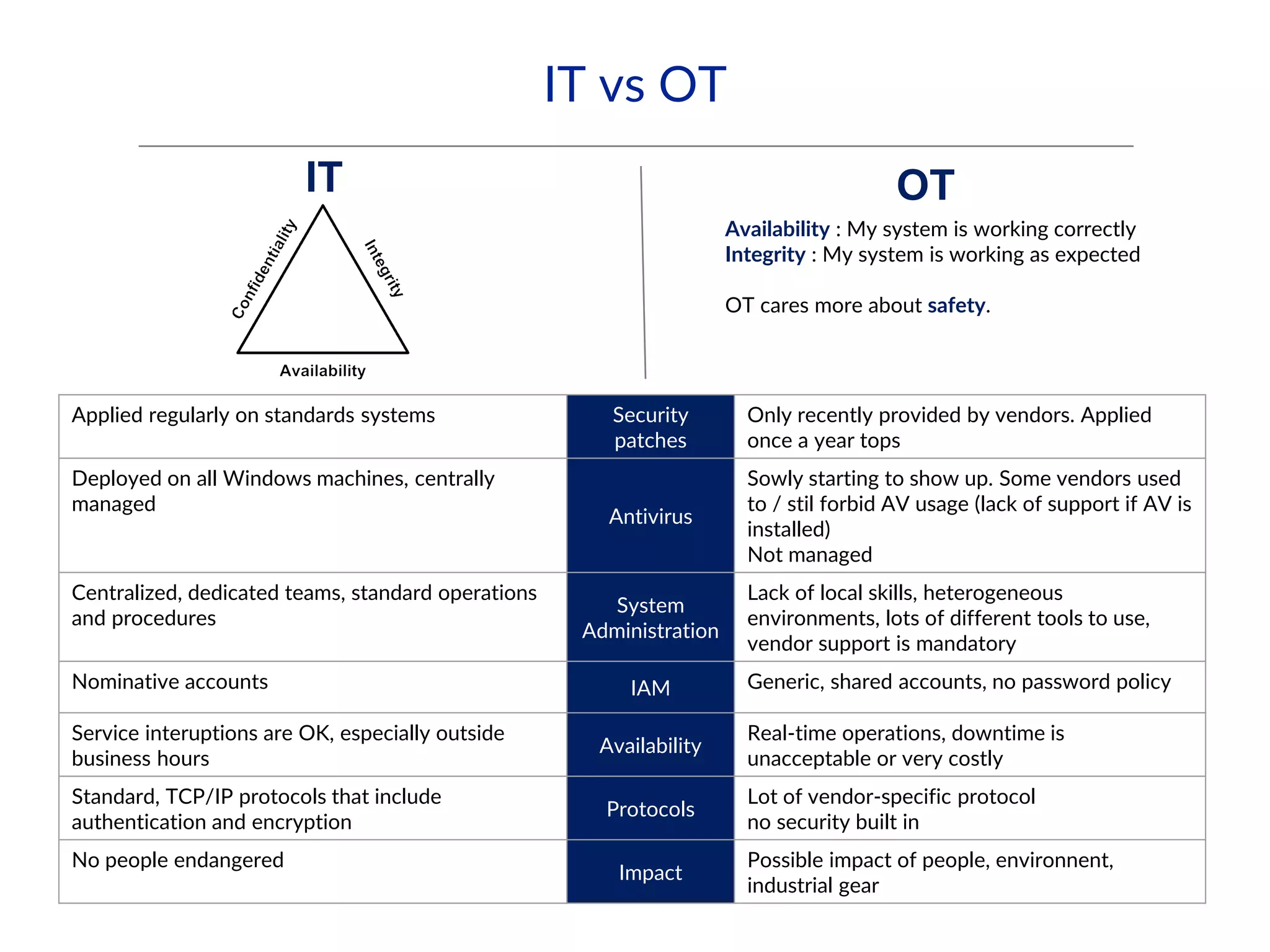

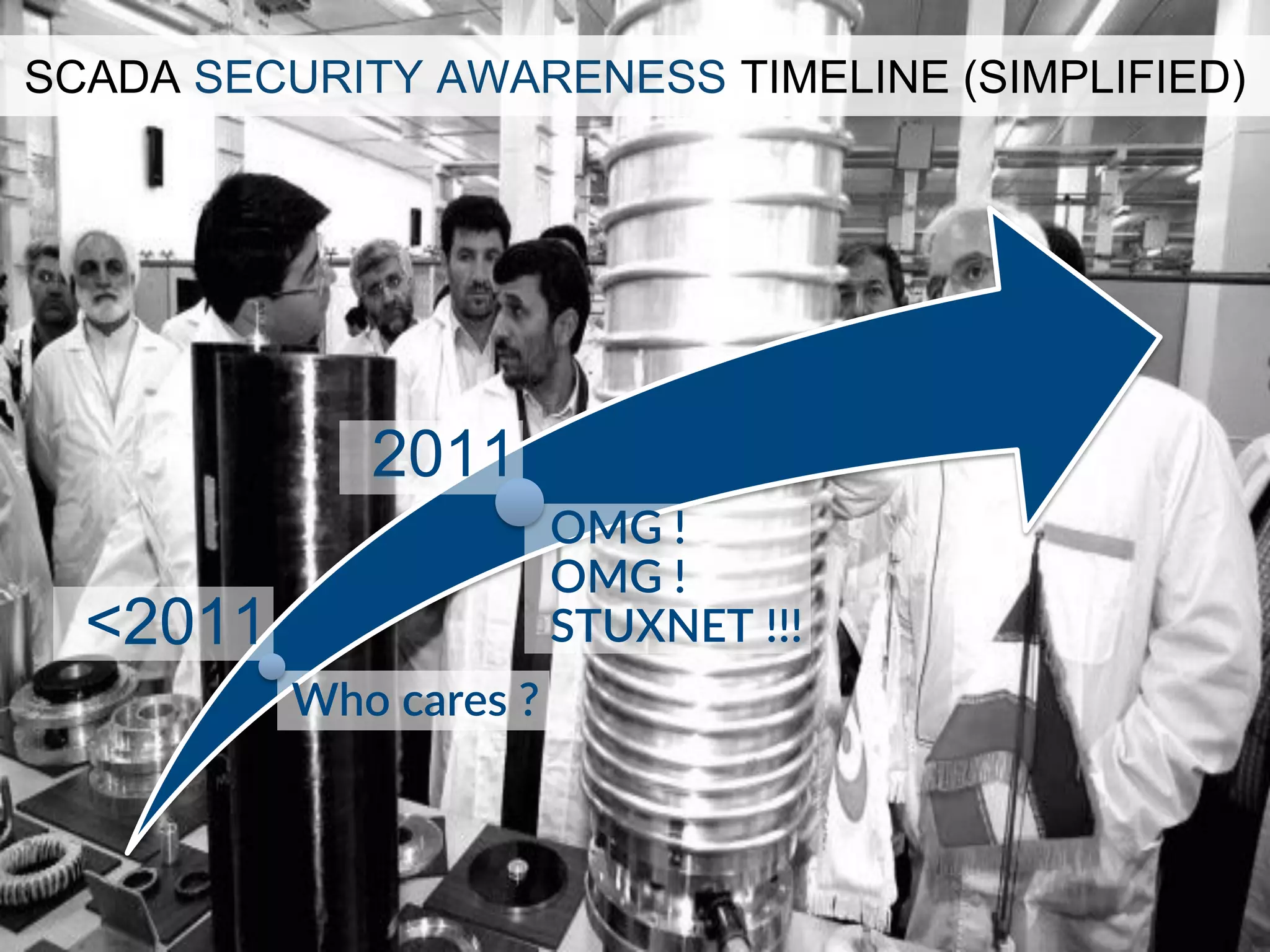

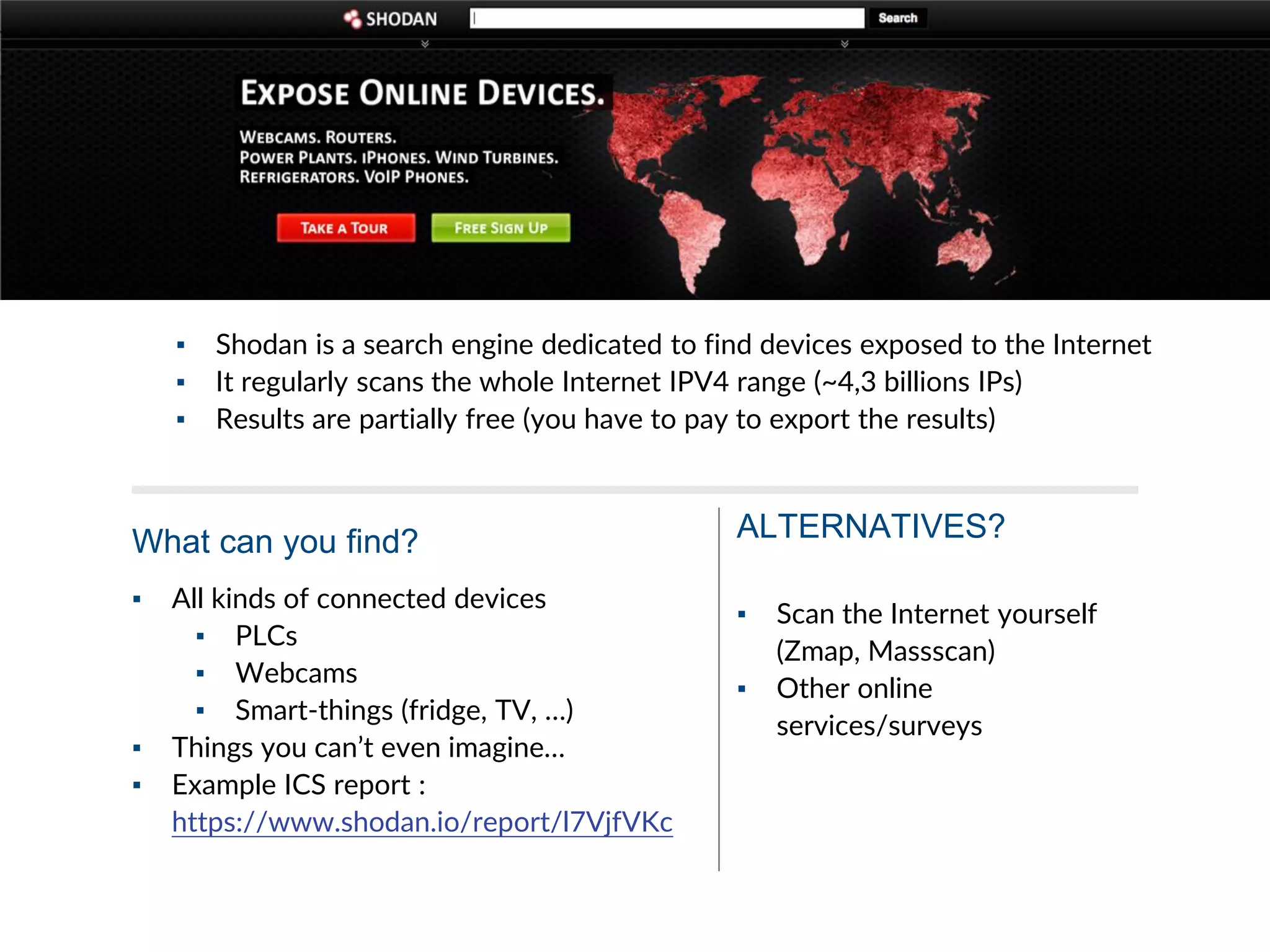

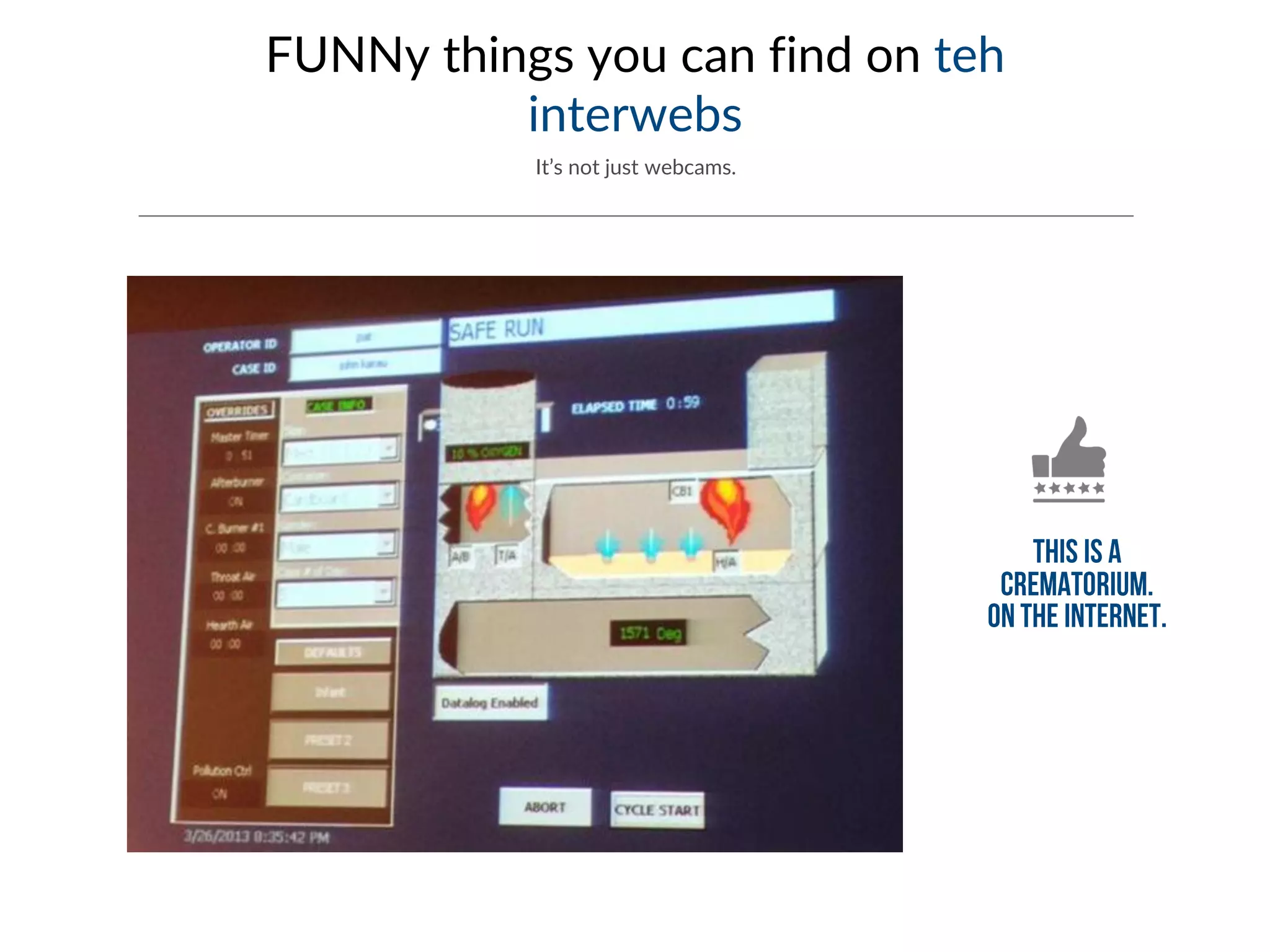

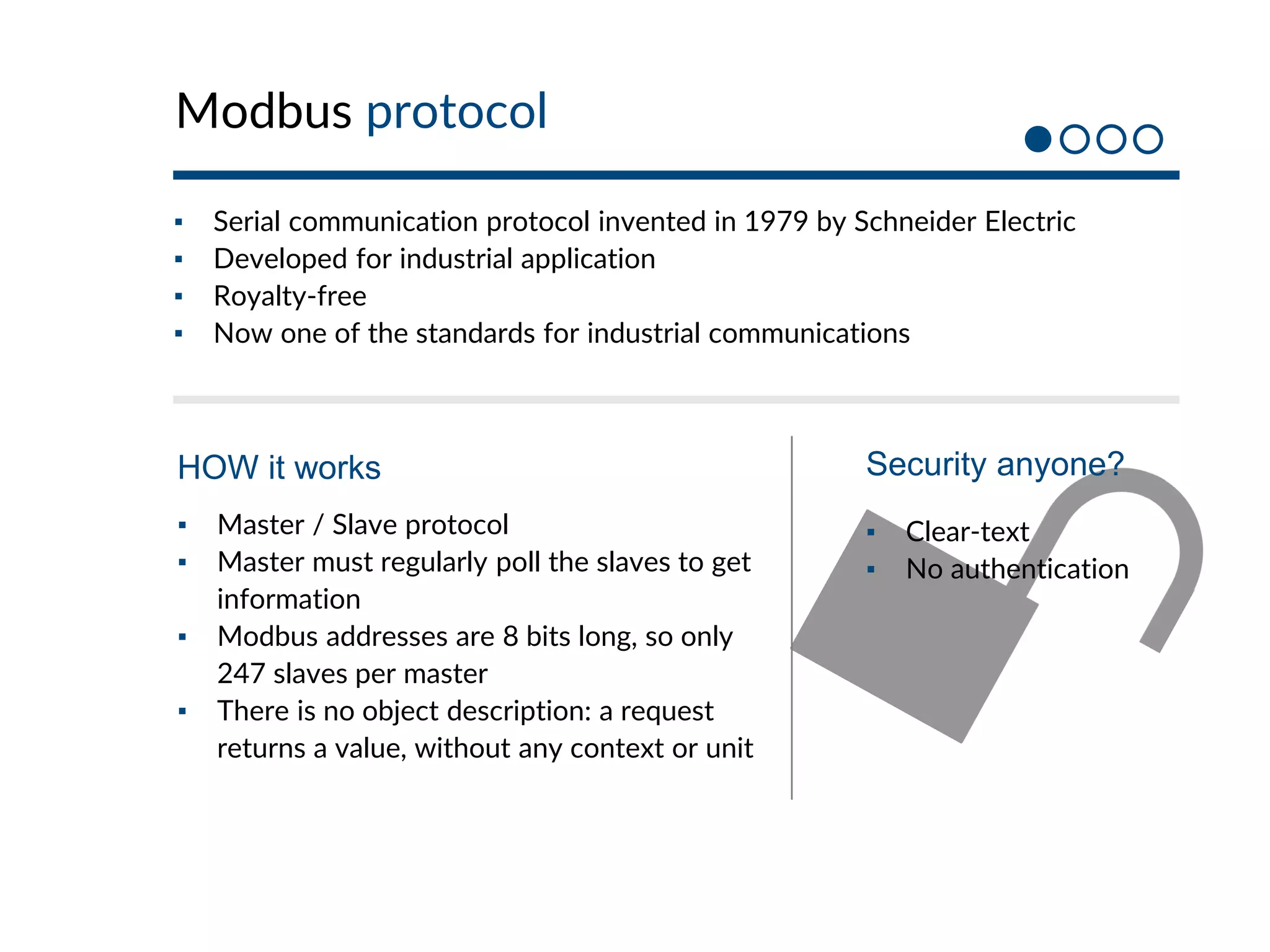

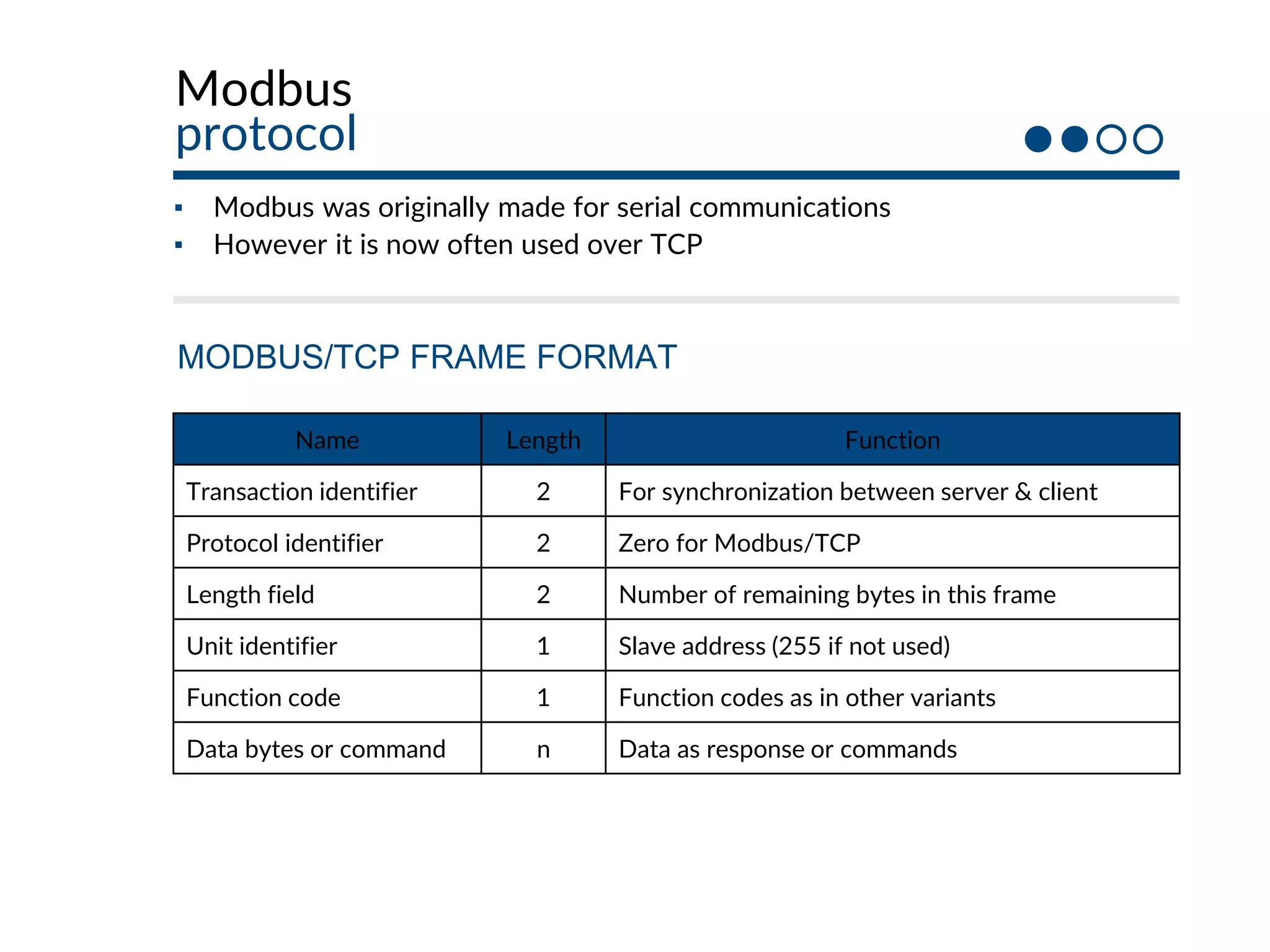

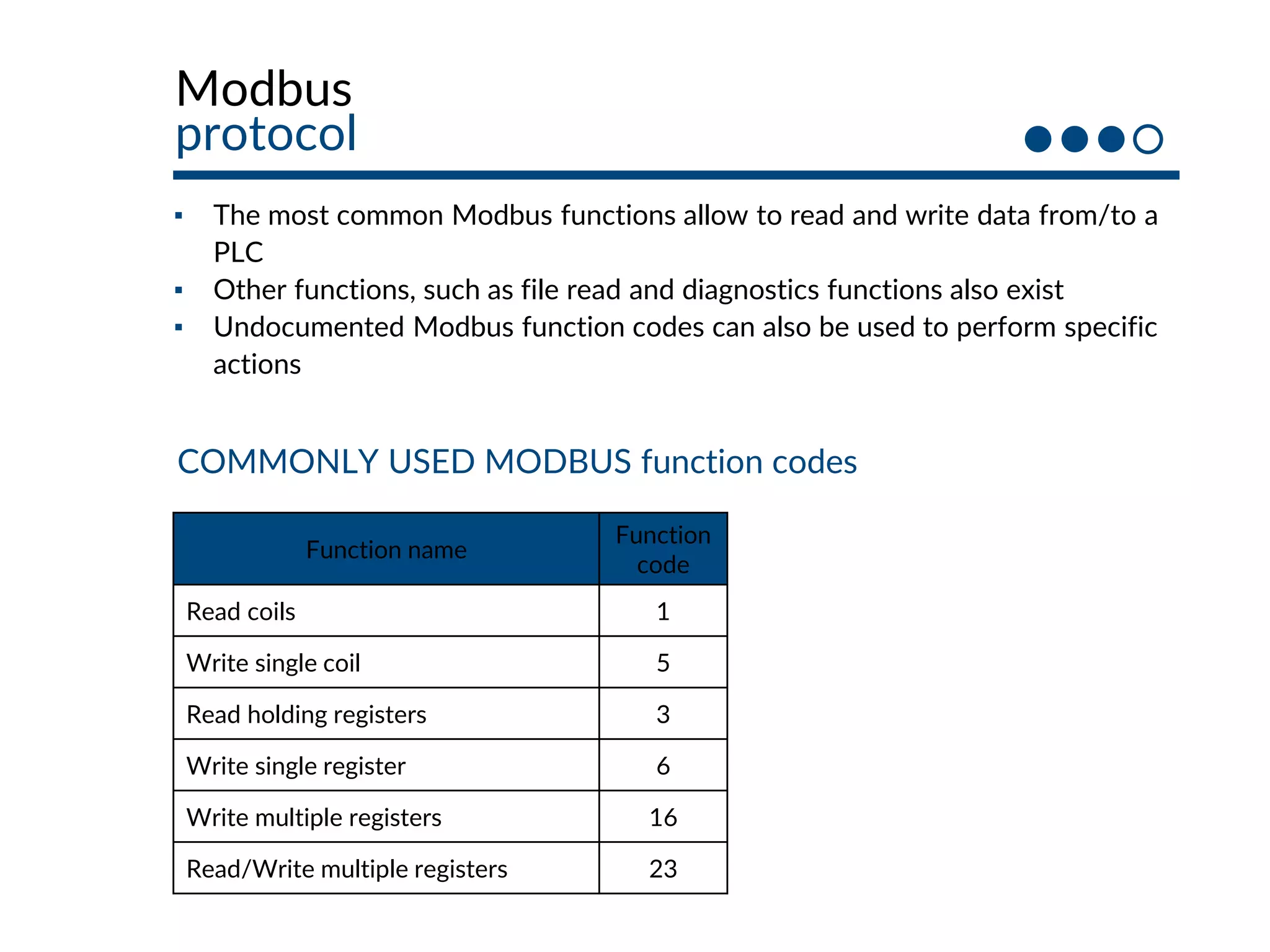

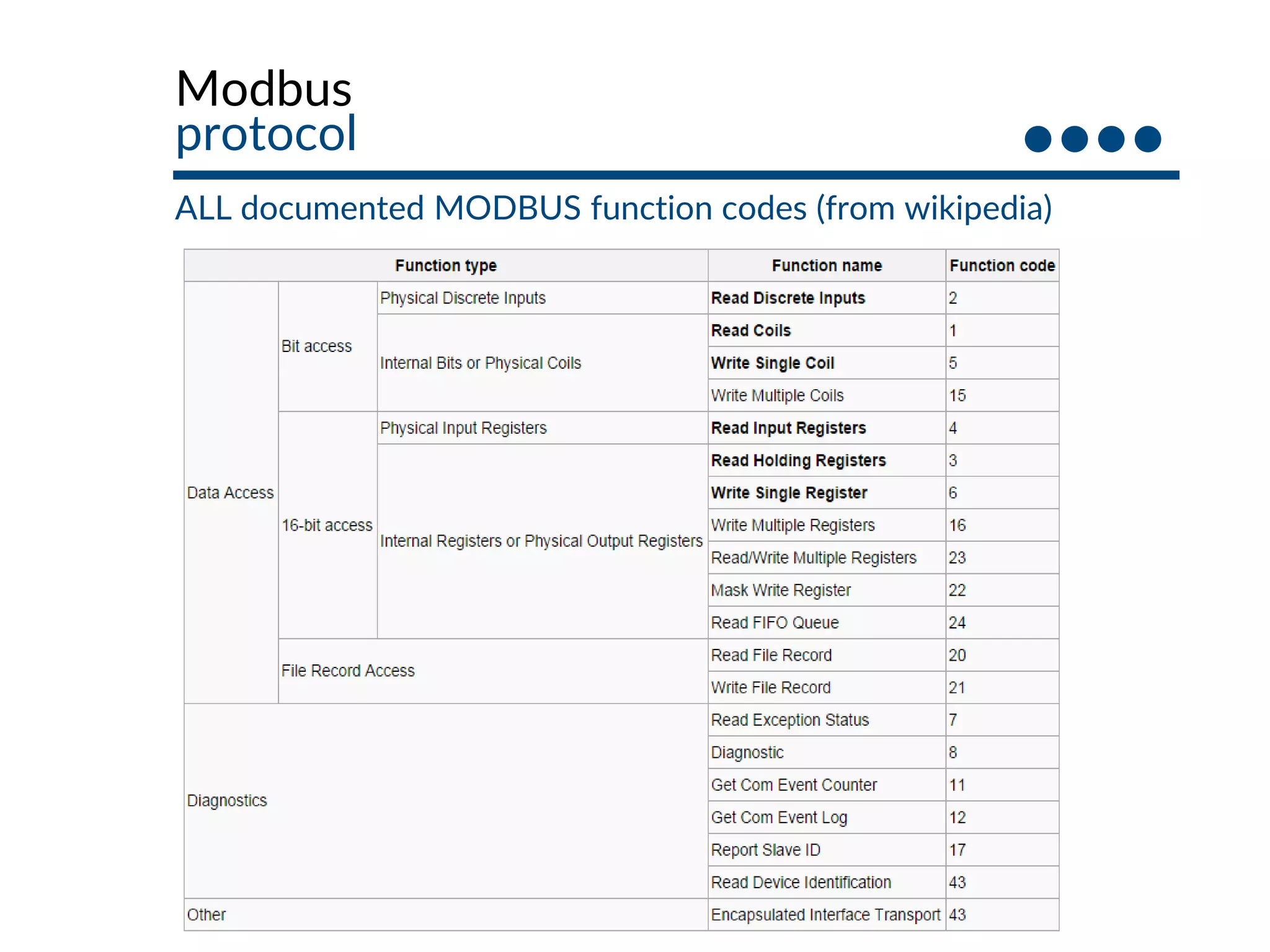

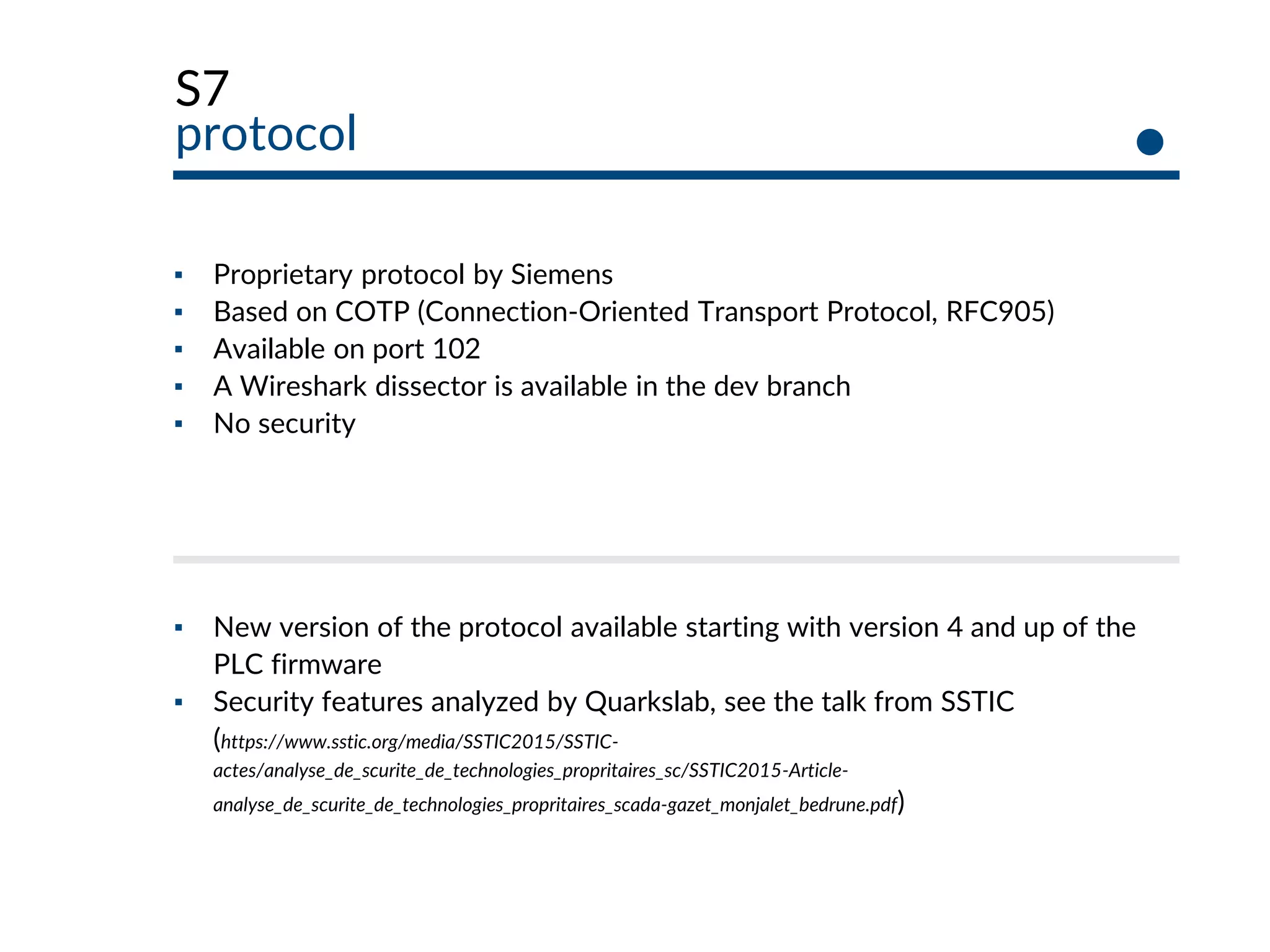

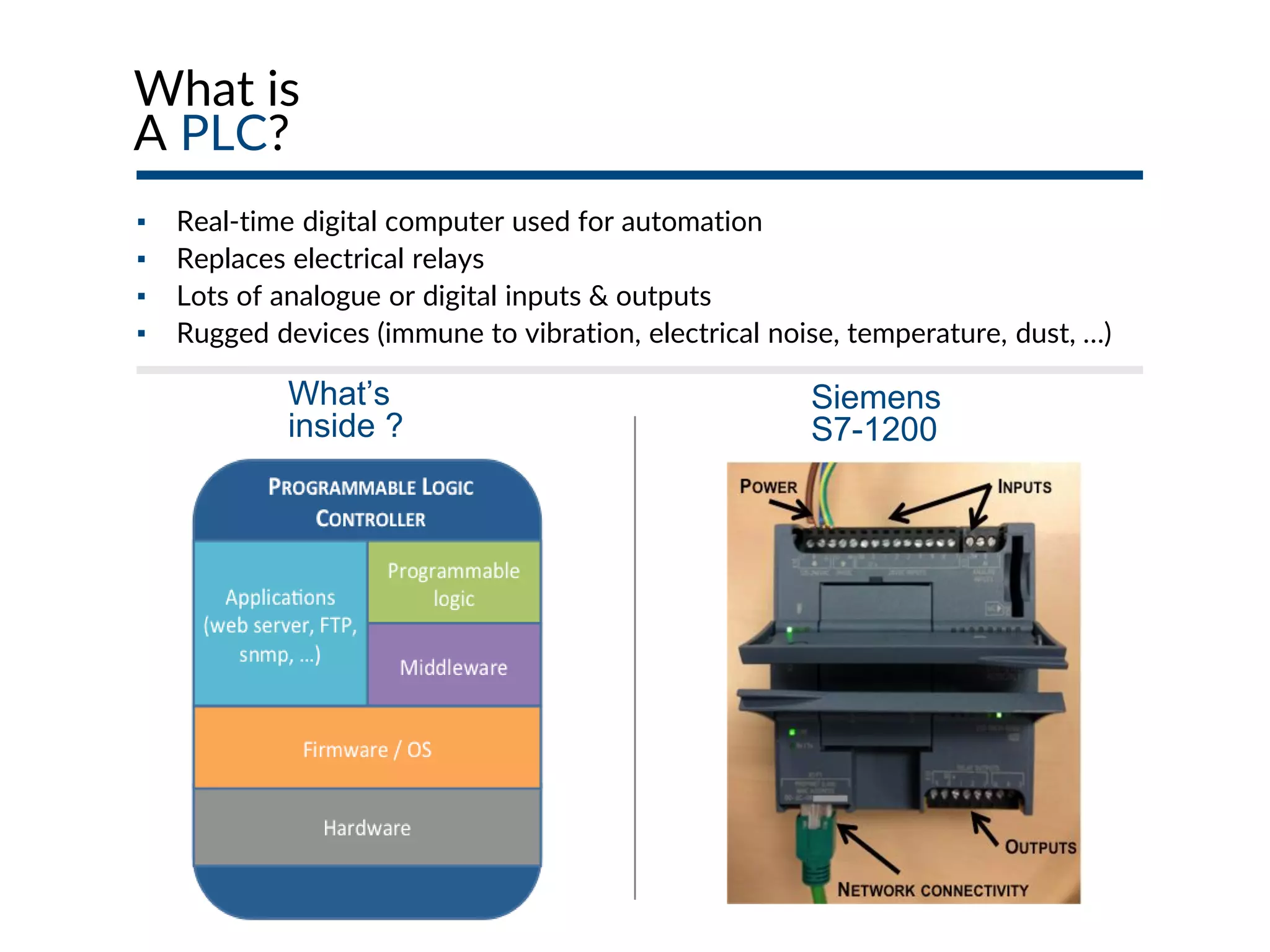

This document provides an overview of industrial control systems (ICS) and SCADA security. It introduces the speakers and defines key ICS terminology. It discusses the evolution of ICS and protocols like Modbus and S7. It outlines ICS components and the differences between IT and OT environments. It also summarizes various tools that can be used for ICS reconnaissance and protocol interaction, and provides an agenda for hands-on lab sessions covering topics like port scanning, protocol analysis and attacks.

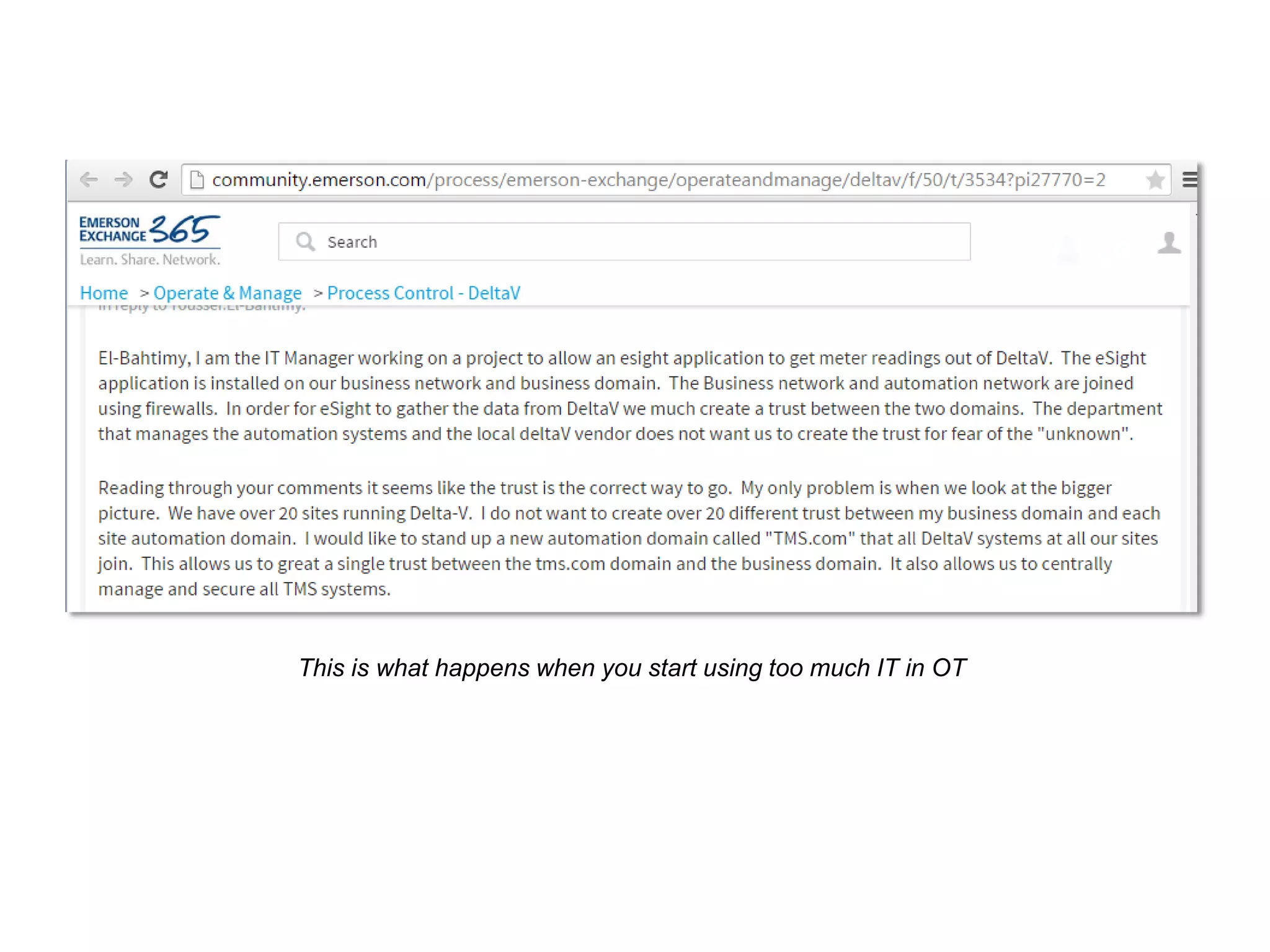

![PLC

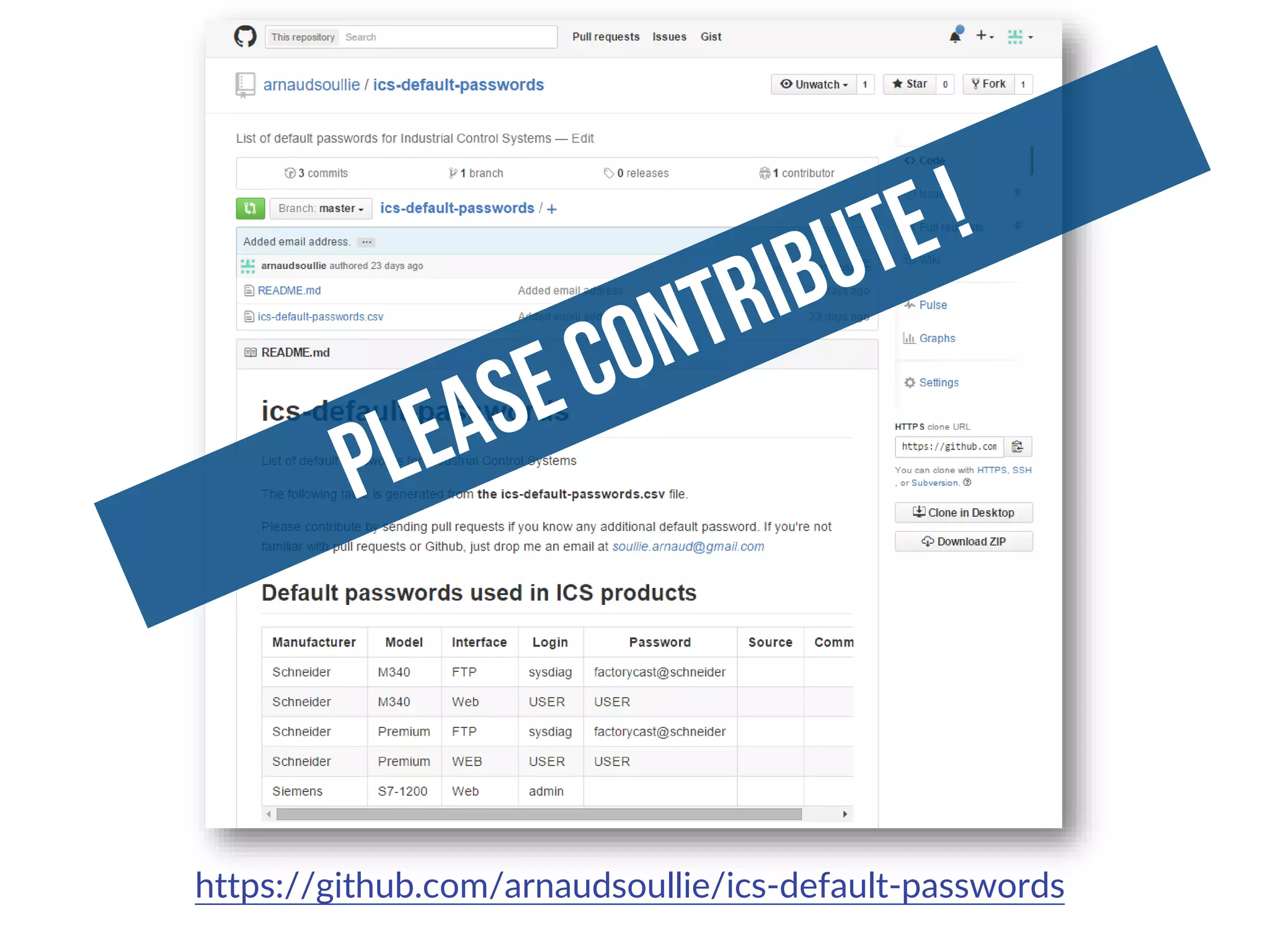

programming

▪ “Ladder Logic” was the first programming language for PLC, as it mimics the

real-life circuits

▪ IEC 61131-3 defines 5 programming languages for PLCs

▪ LD: Ladder Diagram

▪ FBD: Function Block Diagram

▪ ST: Structured Text

▪ IL: Instruction List

▪ SFC: Sequential Function Chart

Ladder diagram

example

Structured text

example

(* simple state machine *)

TxtState :=

STATES[StateMachine];

CASE StateMachine OF

1: ClosingValve();

ELSE

;; BadCase();

END_CASE;

LD Speed

GT 1000

JMPCN VOLTS_OK

LD Volts

VOLTS_OK LD 1

ST %Q75

Instruction list

example](https://image.slidesharecdn.com/brucon2015-pentestingics101-v1-151018085458-lva1-app6892/75/BruCON-2015-Pentesting-ICS-101-41-2048.jpg)