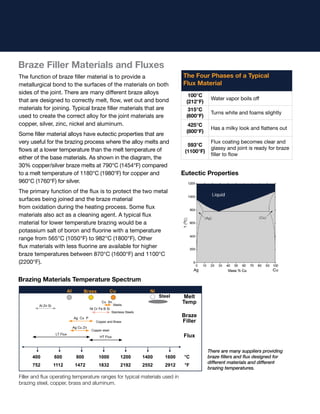

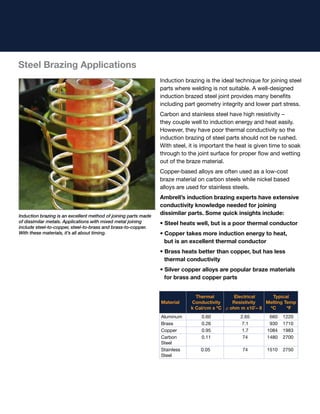

The document provides an overview of induction brazing, a process that joins metals using a filler material at lower temperatures to create strong joints without melting the base metals. It highlights the advantages of induction brazing over traditional methods like torch and furnace brazing, including improved safety, efficiency, and reduced part distortion. Ambrell offers customized systems and expert support for various brazing applications, ensuring high-quality results in manufacturing.