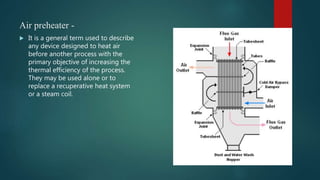

This document discusses boiler mountings, accessories, and types of high pressure boilers. It describes key boiler mountings like the water level indicator, pressure gauge, and safety valves. It also covers boiler accessories that improve efficiency, such as economizers, superheaters, and air preheaters. Finally, it summarizes common high pressure boiler types including La-Mont, Loeffler, and Benson boilers, and notes advantages of high pressure boilers over conventional designs.