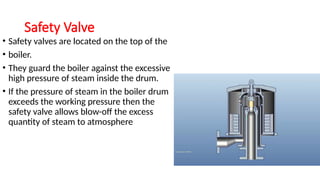

The document outlines the various boiler mountings and accessories essential for the efficient and safe operation of a boiler. Key mountings include the water level indicator, safety valve, pressure gauge, and fusible plug, while accessories such as feed pumps and economizers enhance the boiler's efficiency. It emphasizes the functions of these components in managing water levels, steam pressure, and preventing overheating.