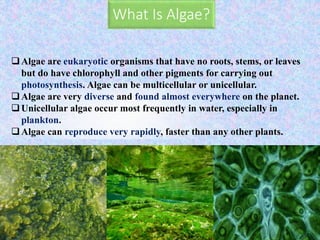

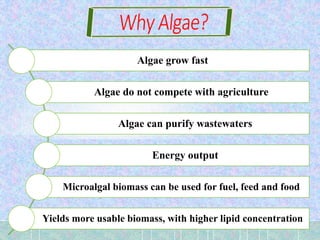

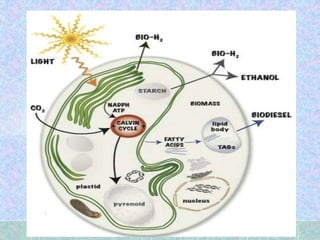

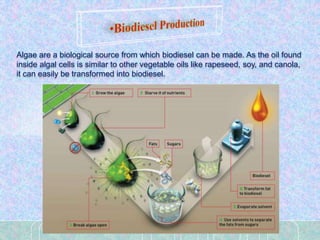

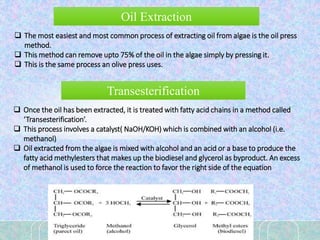

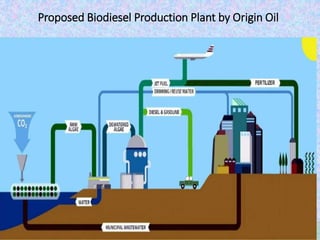

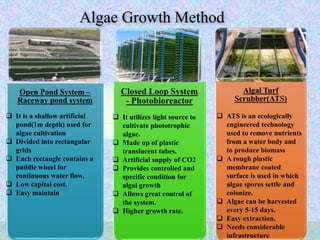

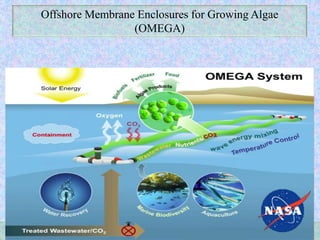

Algae can be used to produce biodiesel through a multi-step process. Algae grow rapidly and can be harvested for their oil, which can then be extracted and treated through transesterification to produce biodiesel. This biodiesel production from algae has advantages over fossil fuels as algae are renewable and do not compete with food sources. Open ponds and closed photobioreactor systems can be used to cultivate the algae. Bangladesh's climate and available resources make it suitable for large-scale algae cultivation and biodiesel production.