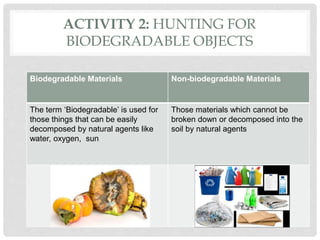

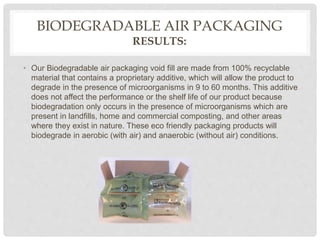

This document outlines activities exploring biodegradable materials. It describes comparing packaging materials and their degradation rates. Processing gelatin into films and testing mechanical properties is discussed. Designing a medicine release capsule that simulates drug delivery in the human body is proposed. A final project proposes biodegradable air packaging as an environmentally-friendly alternative to plastic packaging that degrades within 9-60 months. The document concludes that biodegradable materials can be broken down rapidly by microorganisms.