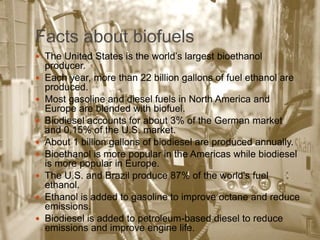

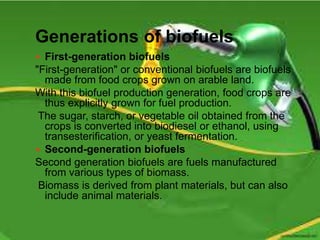

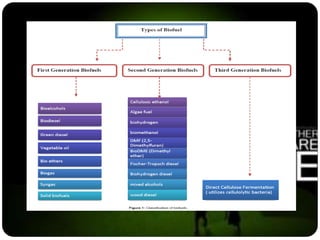

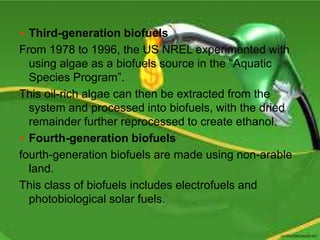

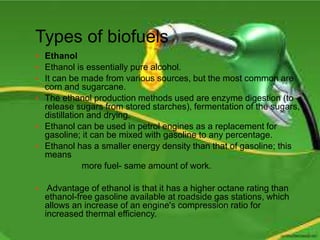

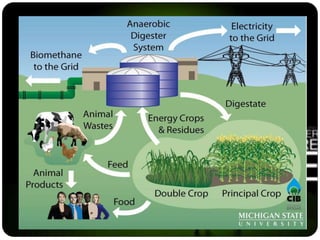

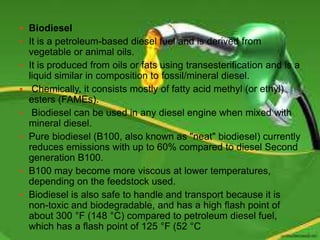

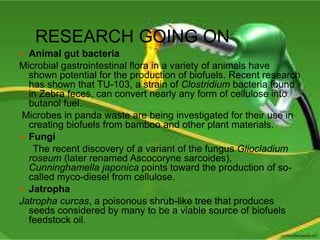

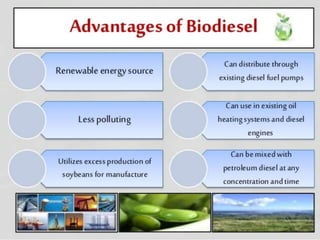

This document discusses biofuels, which are fuels produced from biological sources such as plants and waste. It describes various types of biofuels like ethanol, biodiesel, biogas, and their production methods. Ethanol is made from crops like corn and sugarcane, while biodiesel is made from vegetable oils or animal fats. The document also covers generations of biofuels and ongoing research into producing biofuels from new sources like algae and microbes.

![CONCLUSION

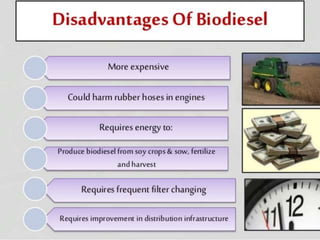

With the increasing demand for fuel and depleting

fossil fuel resources, biofuels can act as a perfect

substitute for gasoline and diesel in the future.

Derived from bio sources, these have least

environmental effects.

While biodiesel remains more expensive than regular

diesel, consumers need to look beyond the cost per

gallon to really gauge the economic benefits.

Biodiesel vehicles get 30 percent better fuel economy

than gasoline-powered vehicles [Consumer Reports].

Above all, biofuels can be readily considered as

renewable sources of energy.](https://image.slidesharecdn.com/biofuels-171128075130/85/Bio-fuels-25-320.jpg)