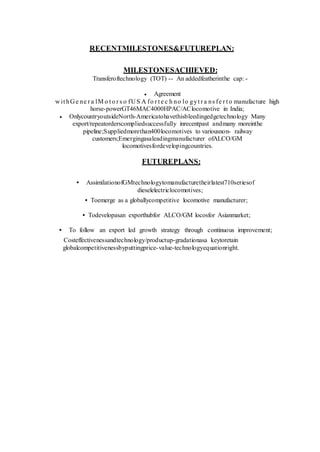

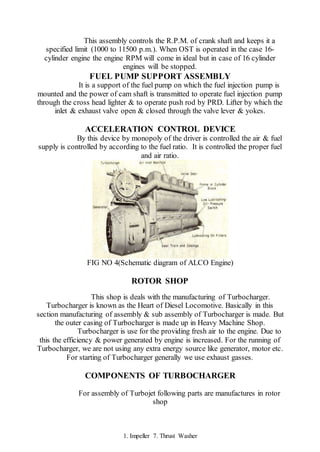

This document summarizes an industrial training project completed by Bheekam Gaur at the Diesel Locomotive Shed in Tughlakabad, New Delhi from June 20, 2016 to July 16, 2016. The 4-week training was part of the requirements for a Bachelor of Technology degree in Mechanical Engineering from the Greater Noida Institute of Technology. The document provides details about the various departments and processes at the locomotive shed, including design office, material control office, production shops for blocks, engines and locomotives, services shops, and personnel, health, civil, and electrical departments. It also discusses the history of the locomotive shed, products manufactured, and future plans.

![TABLE OF CONTENTS

CHAPTER-1

Introduction to Indian Railway………………………………….

CHAPTER 2

History…………………………………………

CHAPTER 3

[3.1].

Conclusion..………………………………………………….CHAPTER

4

[4.1]. Future scope…..………………...…………………………….

[4.2].Bibliography….………………………………………………](https://image.slidesharecdn.com/bh-161020143235/85/Bh-5-320.jpg)